Composite cationic polyacrylamide flocculant and preparation method thereof

A polyacrylamide and cationic technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of enhancing flocculation and sedimentation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

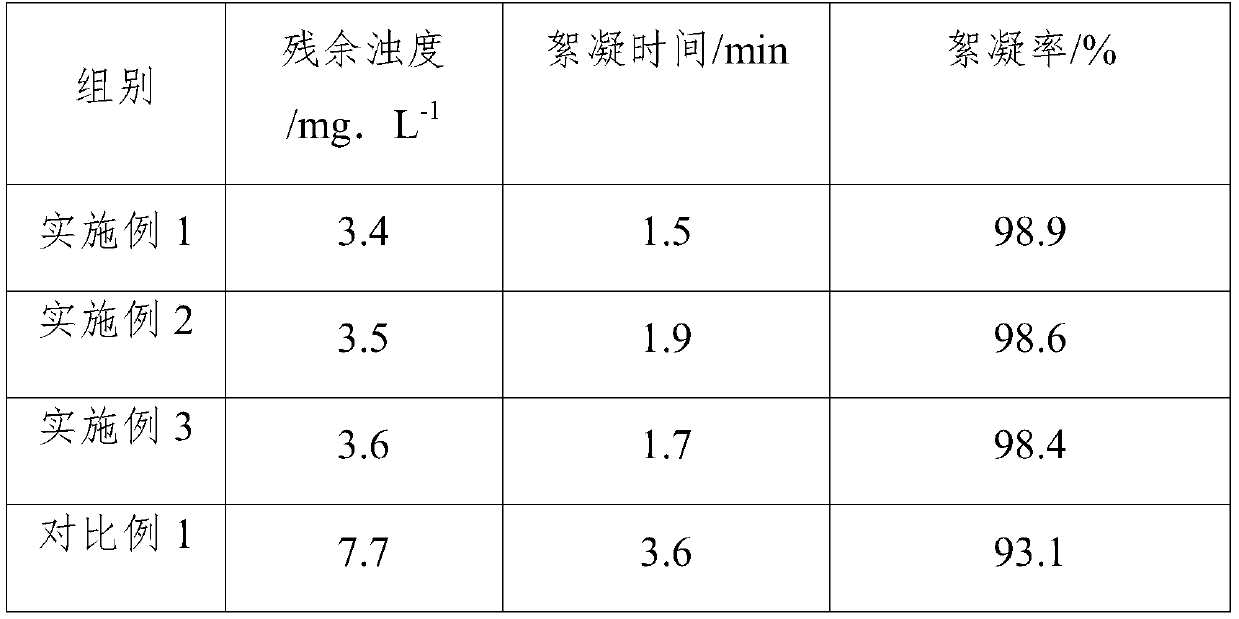

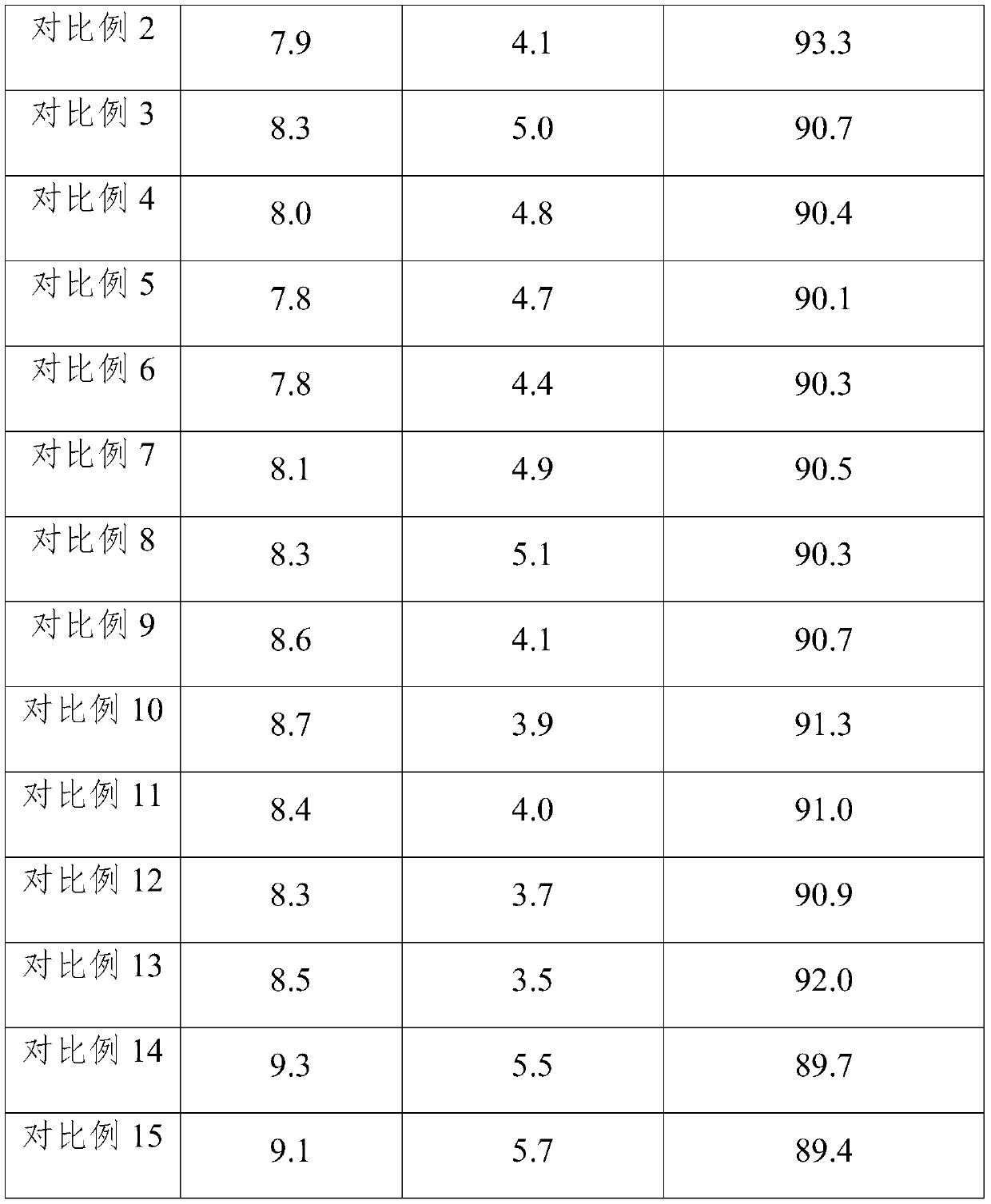

Examples

Embodiment 1

[0023] A composite cationic polyacrylamide flocculant. The composition of the composite cationic polyacrylamide flocculant includes the following raw materials in parts by weight: 65 parts of starch polyacrylamide, 35 parts of activated silicic acid, and 1.5 parts of liquid polyaluminum chloride , 0.7 parts of ammonium thiosulfate, 9 parts of zinc sulfate, 9 parts of magnesium sulfate, 3 parts of 0.1mol / l borax solution, and 95 parts of deionized water.

[0024] A preparation method of a composite cationic polyacrylamide flocculant, comprising the following steps:

[0025] (1) Weigh 1.5 parts of liquid polyaluminum chloride and add it to the reaction kettle, stir the liquid polyaluminium chloride at a speed of 750r / min, weigh and add 17 parts of activated silicic acid at the same time, to obtain Mixture A, standby;

[0026] (2) Weigh the remaining activated silicic acid in proportion, adjust the pH to 1.9 with dilute sulfuric acid, stir at room temperature at a speed of 750r / ...

Embodiment 2

[0029] A composite cationic polyacrylamide flocculant, the composition of the composite cationic polyacrylamide flocculant includes the following raw materials in parts by weight: 50 parts of starch polyacrylamide, 20 parts of activated silicic acid, and 0.9 parts of liquid polyaluminum chloride , 0.1 parts of sodium hypophosphite, 7 parts of zinc sulfate, 7 parts of magnesium sulfate, 1 part of 0.1mol / l borax solution, and 90 parts of deionized water.

[0030] A preparation method of a composite cationic polyacrylamide flocculant, comprising the following steps:

[0031] (1) Take liquid polyaluminum chloride in proportion and add it to the reaction kettle, stir the liquid polyaluminium chloride at a speed of 700r / min, weigh and add 11.25 parts of activated silicic acid at the same time, to obtain Mixture A, standby;

[0032] (2) Weigh the remaining activated silicic acid in proportion, adjust the pH to 1.8 with dilute sulfuric acid, stir for 1 hour at room temperature at a s...

Embodiment 3

[0035] A composite cationic polyacrylamide flocculant, the composition of the composite cationic polyacrylamide flocculant includes the following raw materials in parts by weight: 80 parts of starch polyacrylamide, 50 parts of activated silicic acid, and 2 parts of liquid polyaluminum chloride , 0.5 parts of sodium hydrosulfide, 12 parts of zinc sulfate, 12 parts of magnesium sulfate, 5 parts of 0.1mol / l borax solution, and 100 parts of deionized water.

[0036] A preparation method of a composite cationic polyacrylamide flocculant, comprising the following steps:

[0037] (1) Take liquid polyaluminum chloride in proportion and add it to the reaction kettle, stir the liquid polyaluminium chloride at a speed of 800r / min, weigh and add 20 parts of activated silicic acid at the same time, to obtain Mixture A, standby;

[0038] (2) Weigh the remaining activated silicic acid in proportion, adjust the pH to 2 with dilute sulfuric acid, stir for 1.5 hours at room temperature at a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com