Preparation method for producing acetaldehyde by catalyzing acetylene with ZAPO molecular sieve

A technology for catalyzing acetylene and acetaldehyde with molecular sieves, applied in the chemical field, can solve problems such as environmental hazards and general efficiency, and achieve the effects of reducing production costs, saving resources, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

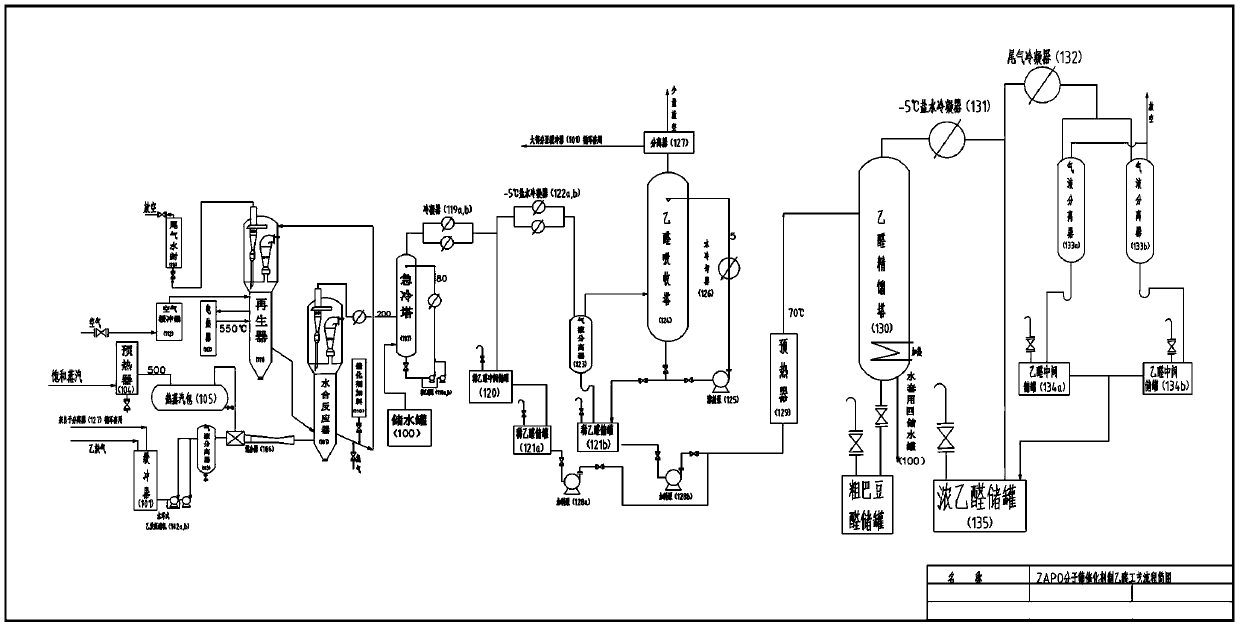

Image

Examples

Embodiment 1

[0032] Embodiment 1: in conjunction with the technological process shown in accompanying drawing, acetylene space velocity is 40.5ml / min 3ml catalyst, and the water and acetylene mole ratio in feed gas is 4.5, and the catalyst used for hydration reaction is ZAPO-5 (zinc aluminum phosphate) molecular sieve catalyst , where the molar ratio of Zn in the framework n(Zn):n(P 2 o 5 )=0.3, the temperature of the hydration reactor is 290°C. The composition and content of the acetaldehyde-based product obtained in the examples were determined by gas chromatography to calculate the conversion rate of acetylene and the selectivity of acetaldehyde.

[0033] The conversion rate of acetylene was measured to be 87.5%, and the selectivity of acetaldehyde was about 98%.

Embodiment 2

[0034] Example 2: In conjunction with the process flow shown in the accompanying drawings, the acetylene space velocity is 15.8ml / min·ml catalyst, the molar ratio of water and acetylene in the feed gas is 2.3, and the catalyst used for the hydration reaction is a ZAPO-5 molecular sieve catalyst, wherein Zn is in the framework The content molar ratio n(Zn):n(P 2 o 5 )=0.4, the temperature of the hydration reactor is 290°C. The composition and content of the acetaldehyde-based product obtained in the examples were determined by gas chromatography to calculate the conversion rate of acetylene and the selectivity of acetaldehyde.

[0035] The conversion rate of acetylene was measured to be 94.2%, and the selectivity of acetaldehyde was about 99%.

Embodiment 3

[0036] Embodiment 3: In conjunction with the technical process shown in the accompanying drawings, the space velocity of acetylene is 14.8ml / min·ml catalyst, the molar ratio of water and acetylene in the feed gas is 2.3, and the catalyst used for the hydration reaction is a ZAPO-5 molecular sieve catalyst, wherein Zn is in the framework The content molar ratio n(Zn):n(P 2 o 5 )=0.5, the temperature of the hydration reactor is 290°C. The composition and content of the acetaldehyde-based product obtained in the examples were determined by gas chromatography to calculate the conversion rate of acetylene and the selectivity of acetaldehyde.

[0037] The conversion rate of acetylene was measured to be 93.8%, and the selectivity of acetaldehyde was about 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com