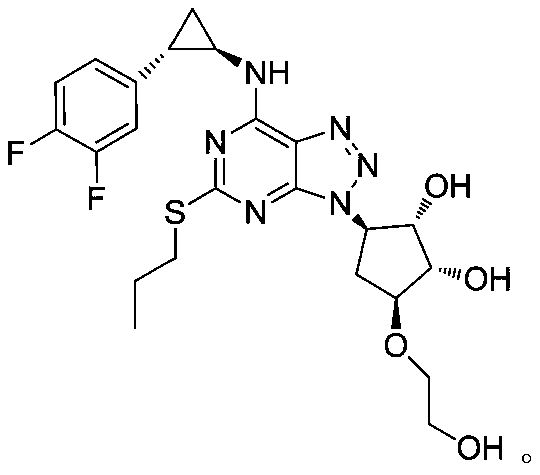

Method for synthesizing ticagrelor intermediate by micro-channel reactor

A technology of microchannel reactors and channel reactors, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical processes, etc., can solve low yield, low purity, exothermic Uncontrollable problems, to achieve the effect of increased purity and yield, reduced impurity content, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: the method for synthesizing ticagrelor intermediate in microchannel reactor.

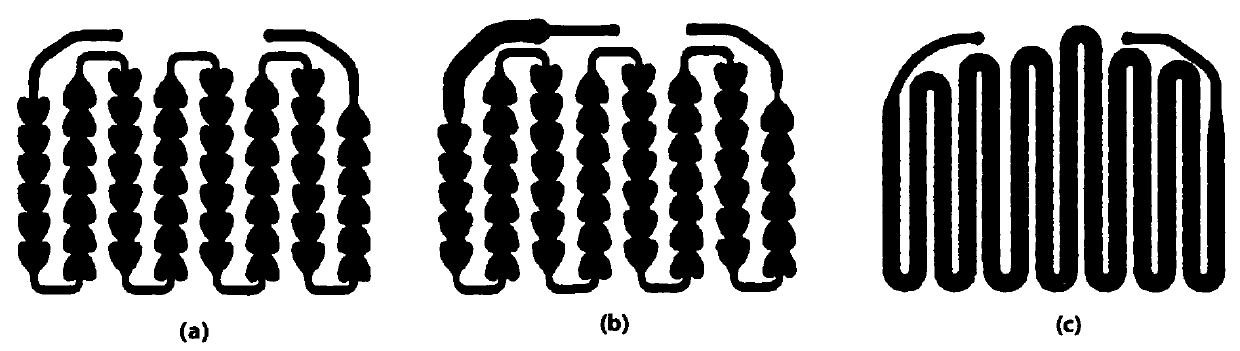

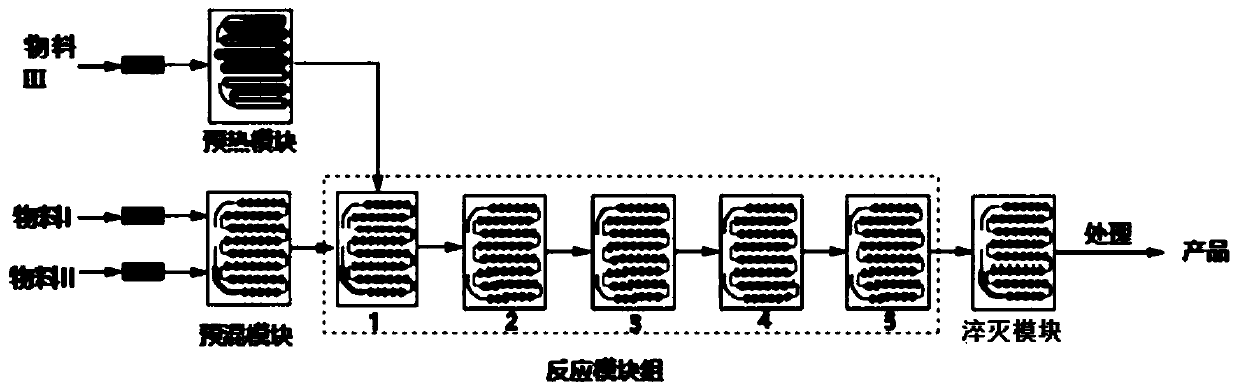

[0034] The present embodiment provides a kind of method that microchannel reactor synthesizes ticagrelor intermediate, such as figure 1 and figure 2As shown, the microchannel reactor adopted includes a preheating module, a premixing module, a reaction module group and a quenching module, wherein: the preheating module is connected in series with the reaction module group, the premixing module is connected in series with the reaction module group, and the reaction module group connected in series with the quenching module.

[0035] 1). Weigh the raw material (3aR,4S,6R,6aS)-6-aminotetrahydro-2,2-dimethyl-4H-cyclopenta-1,3-dioxolane-4- 300 g of alcohol was dissolved in 5 L of tetrahydrofuran to form material I, which was transported to the pre-mixing module of the microchannel reactor for preheating and mixing.

[0036] 2). Take 220g of sodium carbonate and dissolve it in 5L o...

Embodiment 2

[0039] Embodiment 2: the method for synthesizing ticagrelor intermediate in microchannel reactor.

[0040] This embodiment provides a kind of method that microchannel reactor synthesizes ticagrelor intermediate, such as figure 1 and figure 2 As shown, the microchannel reactor adopted includes a preheating module, a premixing module, a reaction module group and a quenching module, wherein: the preheating module is connected in series with the reaction module group, the premixing module is connected in series with the reaction module group, and the reaction module group connected in series with the quenching module.

[0041] 1). Weigh the raw material (3aR,4S,6R,6aS)-6-aminotetrahydro-2,2-dimethyl-4H-cyclopenta-1,3-dioxolane-4- Alcohol 260g is dissolved in the acetonitrile of 3.5L to form material I, and material I is delivered to preheating and mixing in the premixing module of microchannel reactor;

[0042] 2). Weigh potassium carbonate 310g and dissolve it in 5L of water ...

Embodiment 3

[0045] Embodiment 3: the method for synthesizing ticagrelor intermediate in microchannel reactor.

[0046] This embodiment provides a kind of method that microchannel reactor synthesizes ticagrelor intermediate, such as figure 1 and figure 2 As shown, the microchannel reactor adopted includes a preheating module, a premixing module, a reaction module group and a quenching module, wherein: the preheating module is connected in series with the reaction module group, the premixing module is connected in series with the reaction module group, and the reaction module group connected in series with the quenching module.

[0047] 1). Weigh the raw material (3aR,4S,6R,6aS)-6-aminotetrahydro-2,2-dimethyl-4H-cyclopenta-1,3-dioxolane-4- 280g of alcohol is dissolved in 4.2L of tetrahydrofuran to form material I, and material I is transported to the pre-mixing module of the microchannel reactor for preheating and mixing;

[0048] 2). Weigh 172g of sodium carbonate and dissolve it in 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com