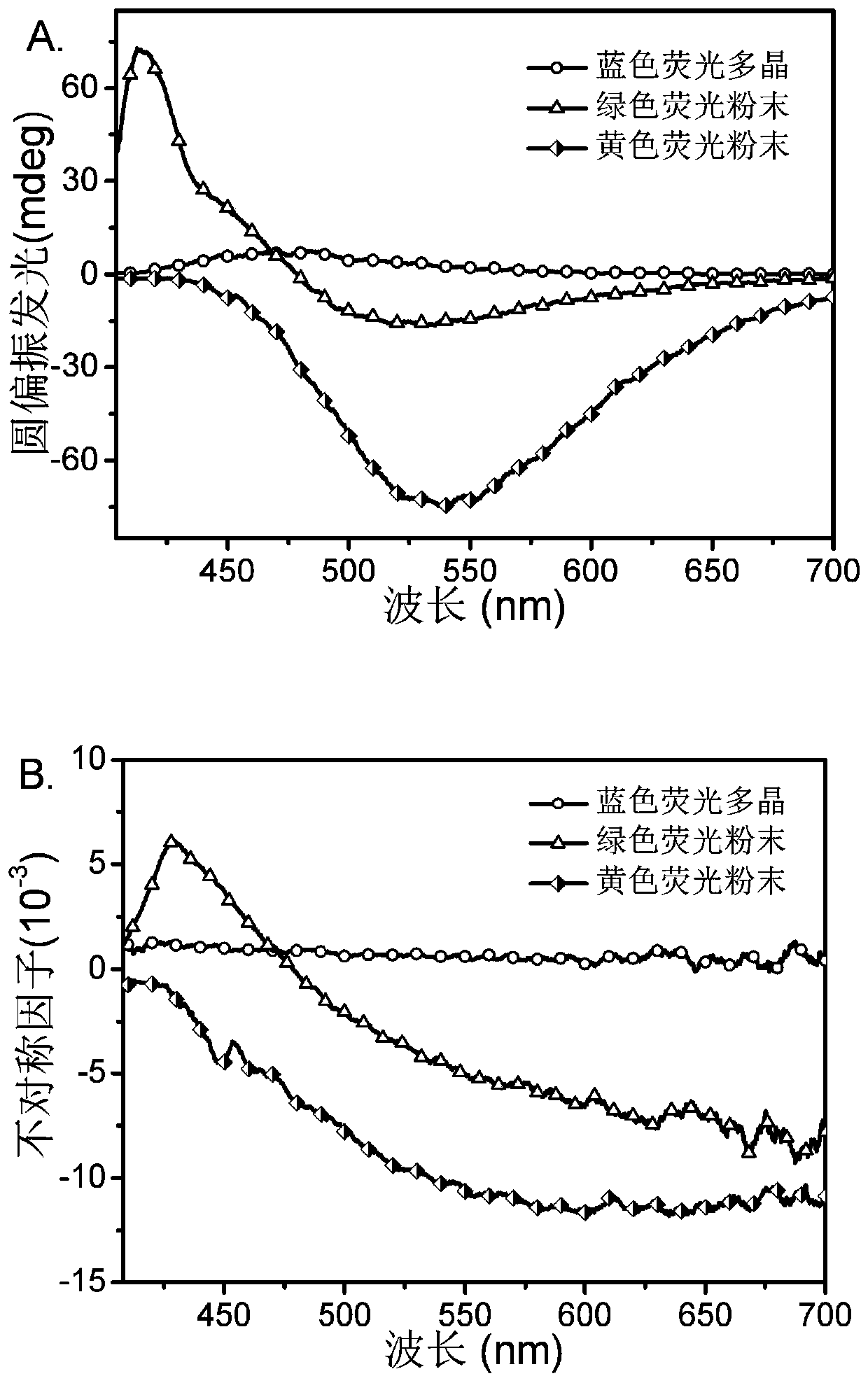

Circular polarization luminescent material with intelligent response multicolor conversion and preparation method and application thereof

A luminescent material and multi-color conversion technology, applied in the field of fluorescent materials, can solve the problems of lengthy and complicated process and low yield, and achieve high fluorescent quantum efficiency, good reversibility, and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Synthesis of circularly polarized luminescent material shown in formula (I)

[0039]Step (1), synthesis of intermediate (II): Weigh cholesteryl formyl chloride (2.24g, 6.0mmol) and dissolve it in dry tetrahydrofuran (25mL), and add the solution dropwise to p-aminobenzyl acetonitrile ( 0.66 g, 5.0 mmol) and triethylamine (2.10 mL, 15 mmol) in dry tetrahydrofuran (30 mL). After stirring at room temperature for 12 hours, the solution was poured into water, and the product was extracted with a 1:3 volume ratio of chloroform / ethanol mixture, and the lower layer of the extract was washed with saturated brine, dried with anhydrous magnesium sulfate, filtered, and the filtrate Concentrate to dryness under reduced pressure. 2.43 g of white solid product intermediate (II) was obtained, with a yield of 89.3%. The structural confirmation of the substance is characterized as follows: 1 H NMR (500MHz, CDCl 3 ): δ (ppm) 7.41 (d, J = 8.35Hz, 2H); 7.26 (d, J = 8.65Hz, ...

Embodiment 2

[0041] Embodiment 2: Synthesis of circularly polarized luminescent material shown in formula (I)

[0042] Step (1), synthesis of intermediate (II): Weigh p-aminophenylacetonitrile (0.66g, 5.0mmol) and pyridine (0.08g, 10mmol) and dissolve in dry chloroform (20mL), and dissolve the solution at -5°C Add dropwise to a solution of cholesteryl formyl chloride (1.87 g, 5.0 mmol) in dry chloroform (25 mL). After stirring at room temperature for 18 hours, the solution was poured into water, and the product was extracted with a 1:2 volume ratio of chloroform / ethanol mixture, and the lower layer of the extract was washed with saturated brine, dried with anhydrous magnesium sulfate, filtered, and the filtrate Concentrate to dryness under reduced pressure. 2.31 g of white solid product intermediate (II) was obtained, with a yield of 84.8%.

[0043] Step (2), synthesis of circularly polarized luminescent material represented by formula (I-m): take intermediate (II) (1.09g, 2.00mmol) prep...

Embodiment 3

[0044] Embodiment 3: Synthesis of circularly polarized luminescent material shown in formula (I)

[0045] Step (1), synthesis of intermediate (II): Weigh cholesteryl formyl chloride (2.24g, 6.0mmol) and dissolve it in dry dichloromethane (25mL), and add the solution dropwise to the solution containing p-aminobenzene at 0°C A solution of acetonitrile (0.66 g, 5.0 mmol) and triethylamine (1.86 mL, 14 mmol) in dry dichloromethane (25 mL). After stirring at room temperature for 10 hours, the solution was poured into water, the product was extracted with a 1:3 volume ratio of chloroform / ethanol mixture, the lower layer of the extract was washed with saturated brine, dried with anhydrous magnesium sulfate, filtered, and the filtrate Concentrate to dryness under reduced pressure. 2.28 g of white solid product intermediate (II) was obtained with a yield of 83.7%.

[0046] Step (2), synthesis of circularly polarized luminescent material represented by formula (I-o): take intermediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com