Inhibitor for LED packaging silica gel as well as preparation method and application of inhibitor

A technology of phenylsilicon and regulator, applied in the directions of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems affecting the light transmittance and compatibility of the silica gel system, and achieve the effect of improving the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] S1. Preparation of Intermediates

[0047] 20.72g 2.58g of methyl acrylate and 0.012g of platinum diacetoacetate were reacted at 50°C for 3h to obtain the following intermediate:

[0048]

[0049] S2. Preparation of acetylenic alcohol compounds containing phenylsiloxane chains

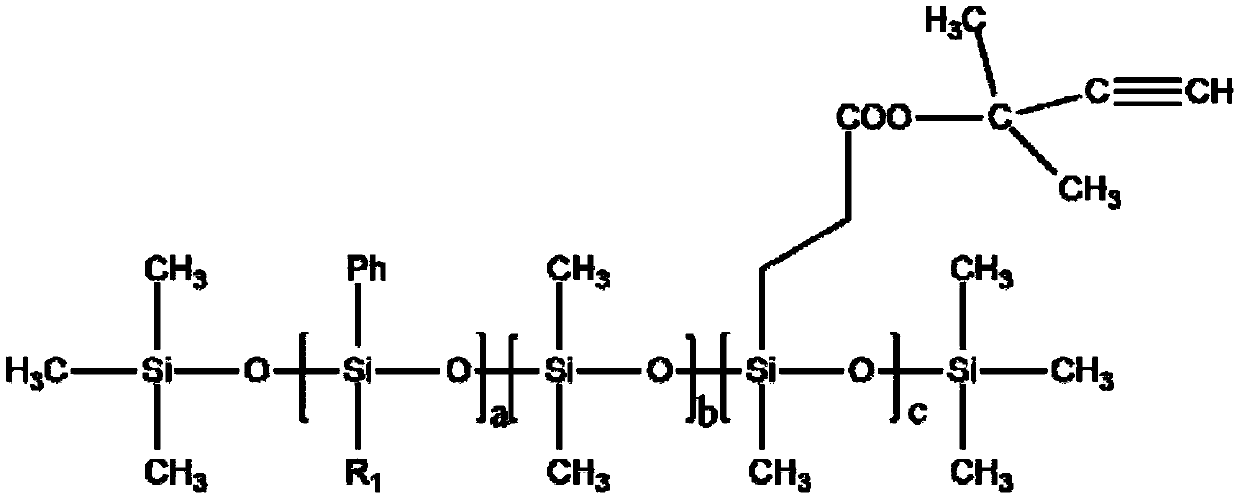

[0050]Mix the intermediate obtained in step S1, 2.52g methyl butynol, 0.13g concentrated sulfuric acid and 12.60g toluene, react at 60°C for 6h, add sodium bicarbonate to adjust the pH of the system to 7, filter, and heat the filtrate to 140 °C, the solvent was removed in vacuo to obtain the following compound with a refractive index of 1.445.

[0051]

Embodiment 2

[0053] S1. Preparation of Intermediates

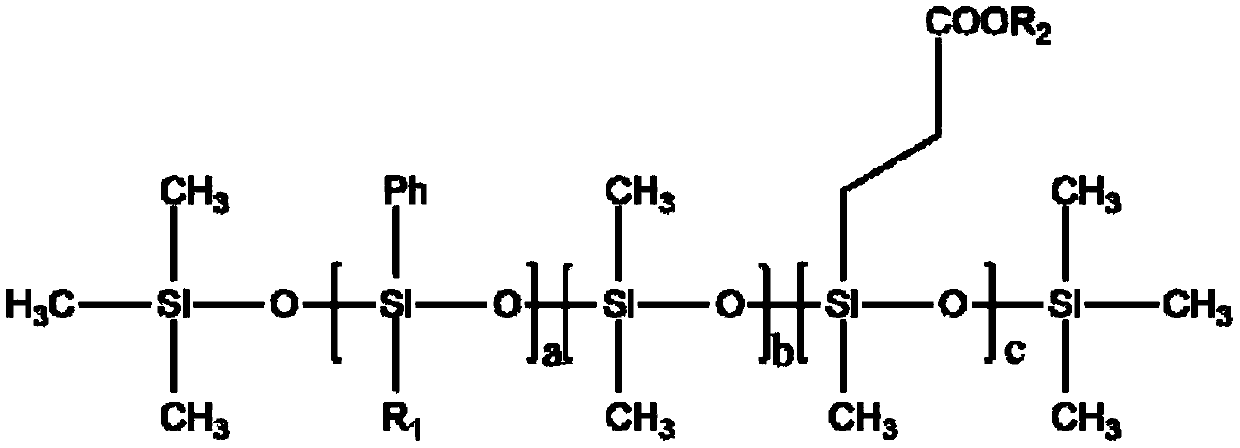

[0054] 38.02g 2.58g of methyl acrylate and 0.02g of platinum diacetoacetate were reacted at 60°C for 1 hour to obtain the following intermediate:

[0055]

[0056] S2. Preparation of acetylenic alcohol compounds containing phenylsiloxane chains

[0057] Mix the intermediate obtained in step S1, 2.52g methyl butynol, 1.27g concentrated sulfuric acid and 43.40g toluene, react at 80°C for 3h, add sodium bicarbonate to adjust the pH of the system to 7, filter, and heat the filtrate to 150 °C, the solvent was removed in vacuo to obtain the following compound with a refractive index of 1.517.

[0058]

Embodiment 3

[0060] S1. Preparation of Intermediates

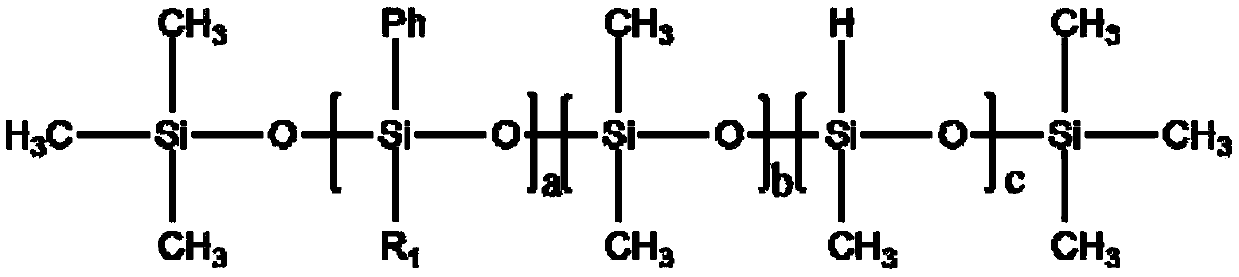

[0061] 30.62g 3.00g of ethyl acrylate and 0.017g of platinum diacetoacetate were reacted at 60°C for 1 hour to obtain the following intermediate:

[0062]

[0063] S2. Preparation of acetylenic alcohol compounds containing phenylsiloxane chains

[0064] Mix the intermediate obtained in step S1, 2.52g methyl butynol, 0.53g concentrated sulfuric acid and 35.00g toluene, react at 80°C for 3h, add sodium bicarbonate to adjust the pH of the system to 7, filter, and heat the filtrate to 150 °C, the solvent was removed in vacuo to obtain the following compound with a refractive index of 1.501.

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com