High refractive index power type LED packaging organosilicon

A technology of LED packaging and power type, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effects of improving UV resistance, realizing continuous adjustability, and improving the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

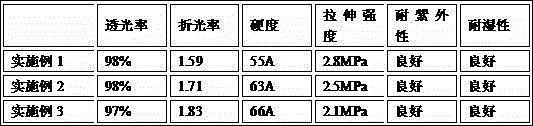

Examples

Embodiment 1

[0033] First carry out the preparation of metal oxide-organic coordination composition:

[0034] S1. Add metal-organic complexes, lower organic alcohols and water for high-temperature aging in a hydrothermal reactor to obtain a white suspension, the metal being titanium; the lower organic alcohol being ethanol;

[0035] S2. centrifuging the suspension obtained in step S1 to obtain nano-oxide particles, and repeatedly washing with absolute ethanol three times;

[0036] S3. Put the nano-oxide particles and coupling agent obtained in step S2 into a three-necked flask in a weight ratio of 1:1~1:50, the coupling agent is vinyl, ultrasonic, then heated and stirred, and centrifuged to obtain modified nano oxide particles;

[0037] S4. Add acid to the modified nano-oxide particles obtained in step S3, and the acid is formic acid to obtain a metal oxide-organic coordination composition.

[0038] Next, prepare component A:

[0039] Add 100 parts of methylphenyl vi...

Embodiment 2

[0043] First carry out the preparation of metal oxide-organic coordination composition:

[0044] S1. Add metal-organic complexes, low-level organic alcohols and water to age in a hydrothermal reaction kettle at high temperature to obtain a white suspension. The metal is mainly zirconium; the low-level organic alcohol is propanol;

[0045] S2. centrifuging the suspension obtained in step S1 to obtain nano-oxide particles, and repeatedly washing with absolute ethanol three times;

[0046] S3. Put the nano-oxide particles obtained in step S2 and the coupling agent at a ratio of 1:1 to 1:20 into a three-necked flask. The coupling agent is methacryloyloxy, ultrasonic, then heated and stirred, and centrifuged to obtain modification Nano oxide particles;

[0047] S4. Add acid to the modified nano-oxide particles obtained in step S3, and the acid is acetic acid to obtain a metal oxide-organic coordination composition.

[0048] Next, prepare component A:

[0049]...

Embodiment 3

[0053] First, the preparation of the metal oxide-organic coordination composition

[0054] S1. Add metal-organic complexes, lower organic alcohols and water to age in a hydrothermal reaction kettle at high temperature to obtain a white suspension, and the metals are mainly one or more of titanium, zirconium or lanthanide rare earth elements; Described lower organic alcohol is Virahol and butanol;

[0055] S2. centrifuging the suspension obtained in step S1 to obtain nano-oxide particles, and repeatedly washing with absolute ethanol three times;

[0056] S3. Put the nano-oxide particles and coupling agent obtained in step S2 into a flask for reaction in a weight ratio of 1:1 to 1:10, and the coupling agent is an epoxy group and an amino group;

[0057] S4. Add acid to the flask in step S3, age, then ultrasonically and centrifuge the suspension to obtain a metal oxide-organic coordination composition, the acid is formic acid, acetic acid, propionic acid, hydrochlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com