High-speed deep stirring drilling machine and construction method thereof

A technology of deep mixing and drilling rigs, which is applied to drilling equipment and methods, rotary drilling rigs, drill pipes, etc. It can solve the problems of self-locking, short working life, and affecting the construction period, and achieve effective transmission of torque and axial force. , Reduction of moving cost and improvement of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

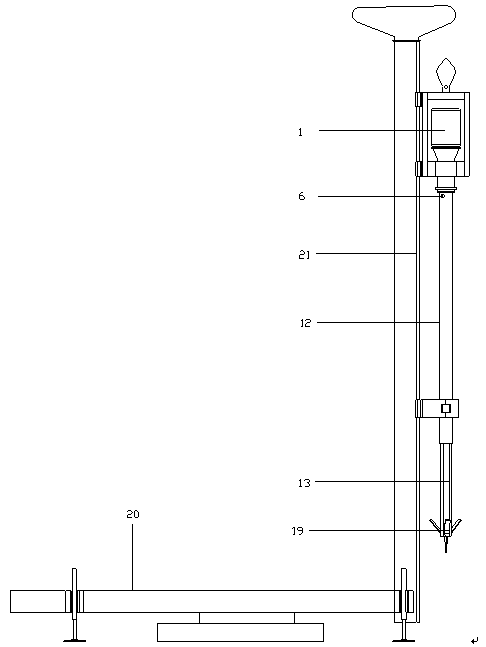

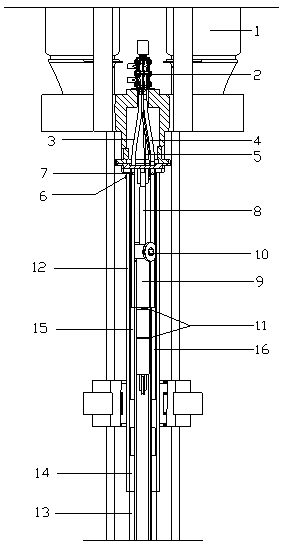

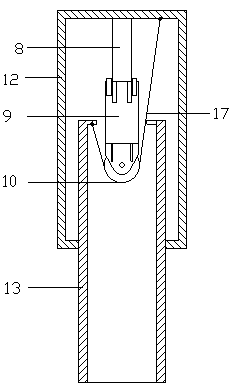

[0033] Such as Figure 1~4 Shown, a kind of high-speed deep mixing drilling rig is characterized in that, comprises chassis 20, drilling rig front end, drilling rig background, power system, pile frame, control platform; Described drilling rig background comprises curing agent mixing system, high-pressure gas supply system; The power system includes oil cylinder power system, circular slewing power system, vertical slewing power system, chassis power system, pile frame power system, drilling rig attachment power system; the front end of the drilling rig includes power head 1, rotary joint 2, air pipe 3, and slurry pipe 4 , hydraulic oil pipe 5, exhaust valve 6, constant pressure valve 7, oil cylinder rod 8, oil cylinder barrel 9, pulley 10, oil cylinder guide sleeve 11, outer drill pipe 12, inner drill pipe 13, drill pipe guide sleeve 14, air pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com