A kind of coated fuel particle containing carbide-refractory metal coating layer and preparation method thereof

A technology for coating fuel particles and refractory metals, applied in the direction of reactor fuel materials, reactor fuel elements, manufacturing reactors, etc., can solve the problems of low compatibility and low compatibility of metal substrates that are prone to damage, and is conducive to rapid prototyping and simplification Preparation process, effect of design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

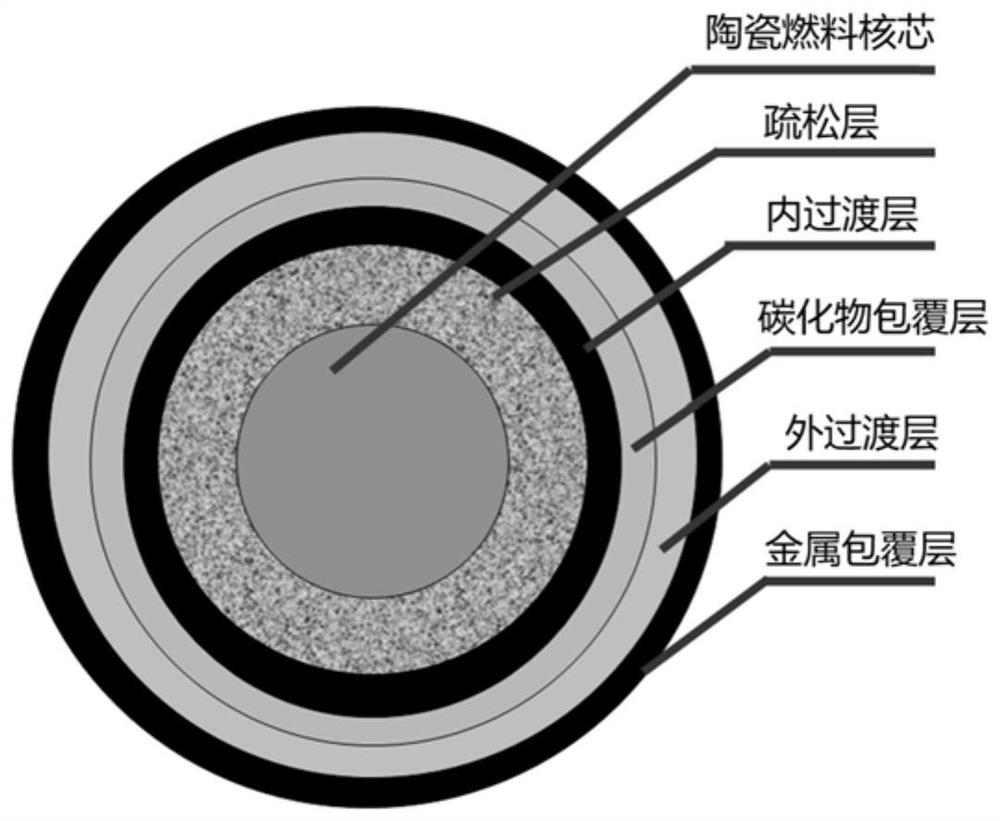

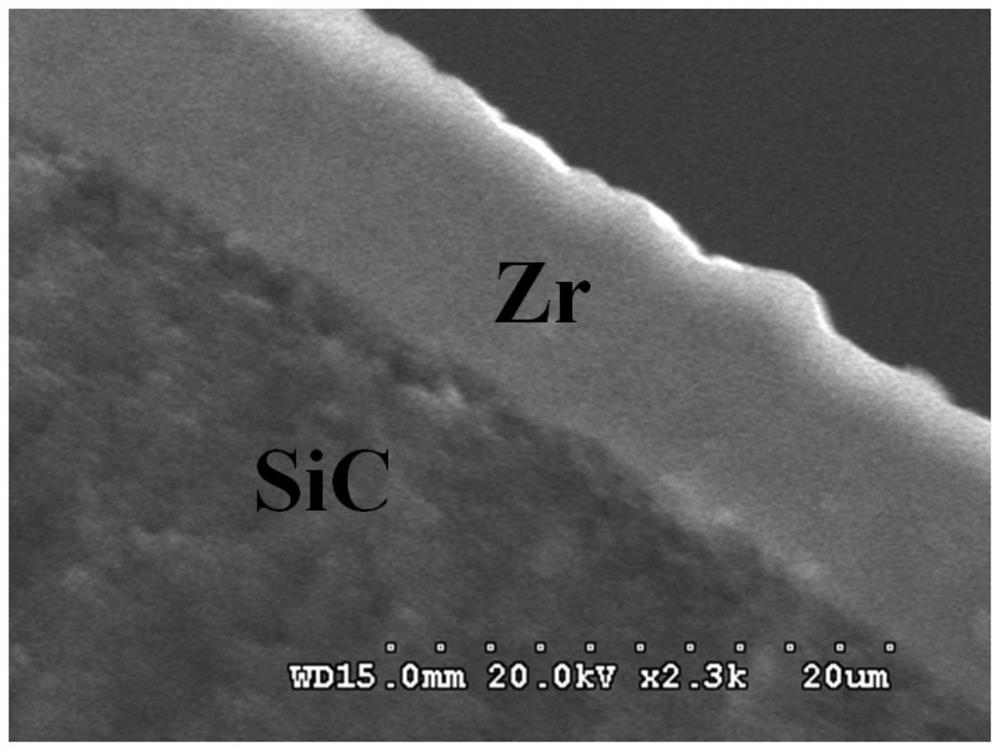

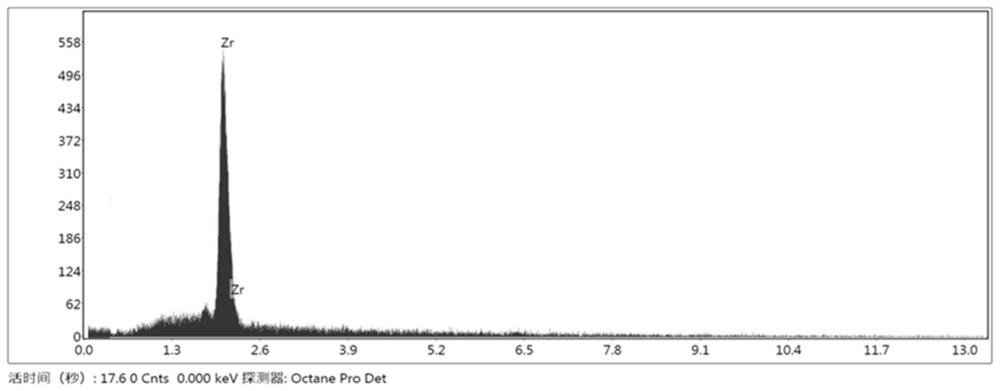

[0042] A new type of coated fuel particles, the schematic diagram of its structure is shown in figure 1 , the new coated fuel particles include a uranium dioxide ceramic fuel core and a loose layer of pyrolytic carbon, an inner transition layer of pyrolytic carbon, a silicon carbide coating, and a pyrolytic carbon layer coated sequentially outside the ceramic fuel core. Carbon outer transition layer and metallic zirconium coating;

[0043] Wherein, the uranium dioxide ceramic fuel core is a sphere with a diameter of 500-600 μm;

[0044] The density of the pyrolytic carbon loose layer is 0.8g / cm 3 , the porosity is 62%, and the thickness is 90-100μm.

[0045] The inner transition layer of the pyrolytic carbon has a thickness of 20-30 μm and a density of 1.9 g / cm 3 ;

[0046] The thickness of the silicon carbide cladding layer is 30-35 μm;

[0047] The thickness of the outer transition layer of pyrolytic carbon is 1-2 μm;

[0048] The thickness of the metal zirconium clad...

Embodiment 2

[0059] A novel coated fuel particle, the novel coated fuel particle comprises a uranium nitride ceramic fuel core and a silicon carbide loose layer, a pyrolytic carbon inner transition layer, and niobium carbide which are sequentially coated on the outside of the ceramic fuel core cladding layer, pyrolytic carbon outer transition layer and metal niobium cladding layer;

[0060] Wherein, the uranium nitride ceramic fuel core is a sphere with a diameter of 800-900 μm;

[0061] The density of the silicon carbide loose layer is 2.0g / cm 3 , the porosity is 38%, and the thickness is 90-100μm.

[0062] The inner transition layer of the pyrolytic carbon has a thickness of 10-15 μm and a density of 1.9 g / cm 3 ;

[0063] The thickness of the niobium carbide cladding layer is 30-35 μm;

[0064] The thickness of the outer transition layer of pyrolytic carbon is 2-3 μm;

[0065] The thickness of the metal niobium cladding layer is 30-40 μm.

[0066] The preparation method of above-me...

Embodiment 3

[0075] A new type of coated fuel particles, the schematic diagram of its structure is shown in figure 1 , the new coated fuel particles include a uranium carbon oxide (UCO) ceramic fuel core and a pyrolytic carbon loose layer, a pyrolytic carbon inner transition layer, and a zirconium carbide coating layer that are sequentially coated on the outside of the ceramic fuel core , Pyrolytic carbon outer transition layer and zirconium-tantalum alloy cladding layer;

[0076] Wherein, the UCO ceramic fuel core is a sphere with a diameter of 600-700 μm;

[0077] The density of the pyrolytic carbon loose layer is 1.0g / cm 3 , the porosity is 52%, and the thickness is 70-80μm.

[0078] The inner transition layer of the pyrolytic carbon has a thickness of 20-25 μm and a density of 1.8 g / cm 3 ;

[0079] The thickness of the zirconium carbide cladding layer is 50-55 μm;

[0080] The thickness of the outer transition layer of pyrolytic carbon is 3-4 μm;

[0081] The thickness of the zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com