Method for preparing crystalline silicon solar cell electrode

A solar cell and electrode technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of battery performance degradation, battery performance degradation, and printability degradation, so as to improve battery electrical performance, ensure over-ink performance, and reduce manufacturing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

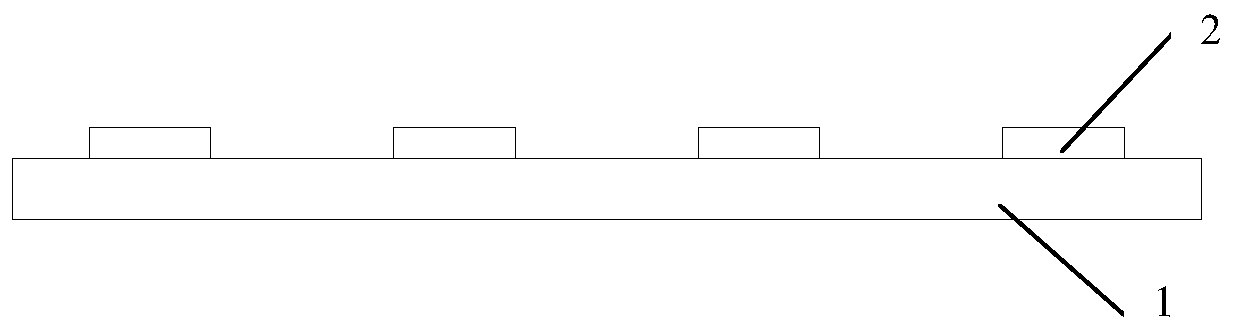

[0035] Such as figure 1 Shown, is a kind of method for preparing crystalline silicon solar cell electrode of the present invention, specifically comprises the following steps:

[0036] S1. Prepare a cured film layer 2 on the position corresponding to each electrode on the silicon wafer substrate 1. The material of the cured film layer 2 is wax. Specifically, the wax is heated and melted by heating the screen printing method, and printed on the silicon wafer substrate. 1 on. The wax is naturally cooled and solidified during the transmission process, forming a solidified film layer 2;

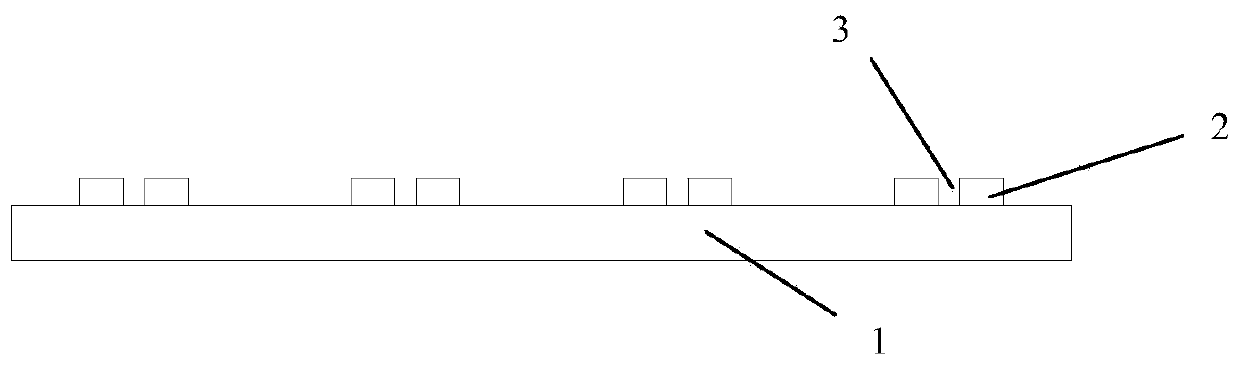

[0037] S2. Use a laser to open a groove 3 on the cured film 2 along the electrode extension direction, the groove 3 penetrates the cured film 2, and the width of the groove 3 is smaller than the width of the cured film 2;

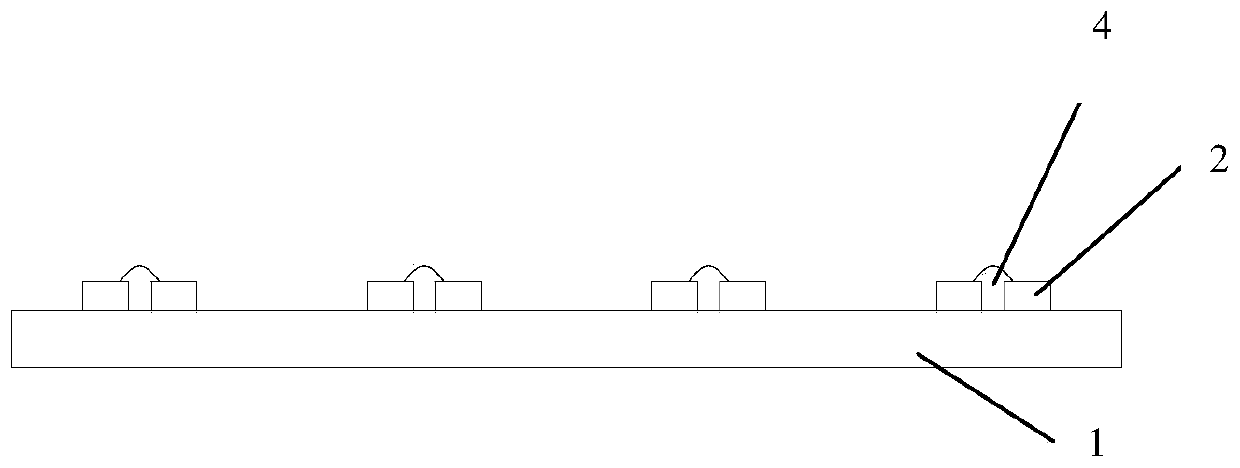

[0038] S3, using the method of screen printing, filling the electrode slurry 4 in the groove 3, the electrode slurry 4 is a low-viscosity slurry, which is a prior art, speci...

Embodiment 2

[0041] A kind of method for preparing crystalline silicon solar cell electrode of the present invention specifically comprises the following steps:

[0042] S1. Prepare a cured film layer at the position corresponding to each electrode on the silicon wafer base. In this embodiment, the material of the cured film layer is UV-cured acrylic resin. Form a layer of cured film;

[0043] S2. Use a laser to open a groove on the cured film layer along the electrode extension direction, the groove penetrates the cured film layer, and the width of the groove is smaller than the width of the cured film layer;

[0044] S3, use the method of screen printing to fill the electrode slurry in the groove, the electrode slurry is a low-viscosity slurry, which is the prior art, specifically the common slurry of Heraeus produced by DuPont , reduce the viscosity to 5~250×10 by adding diluent -3 Pa·s is available. The main function of the wax layer is to support the metal electrode grid lines and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com