Preparation method of metal matrix composite conductor blank

A metal matrix composite and metal material technology is applied in the field of preparation of metal matrix composite wire blanks, which can solve the problems of unsatisfactory composite ratio, high extrusion processing cost, low yield, etc., and reduce welding process and time. , The effect of simplifying the assembly process and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

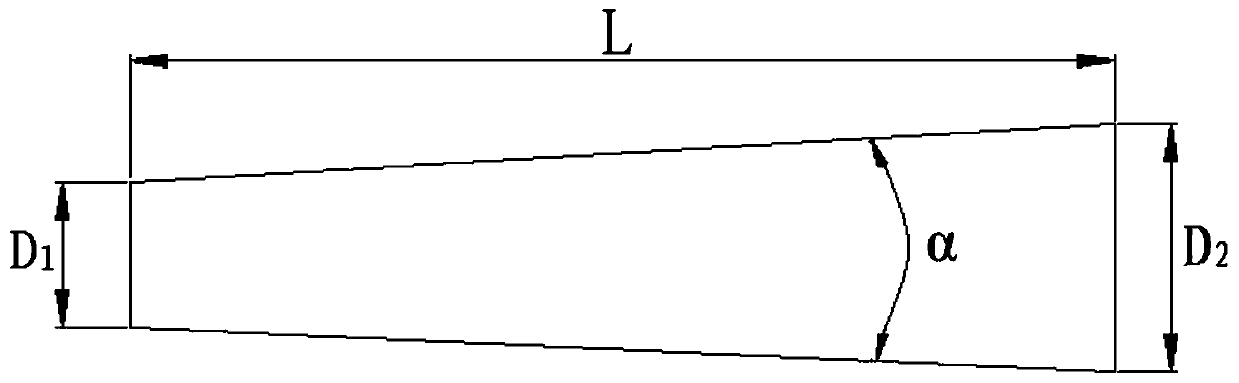

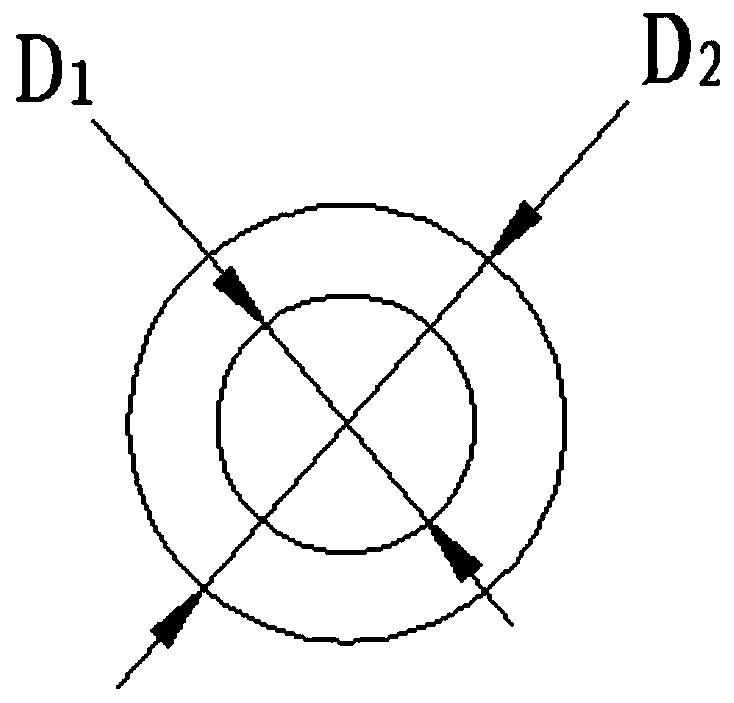

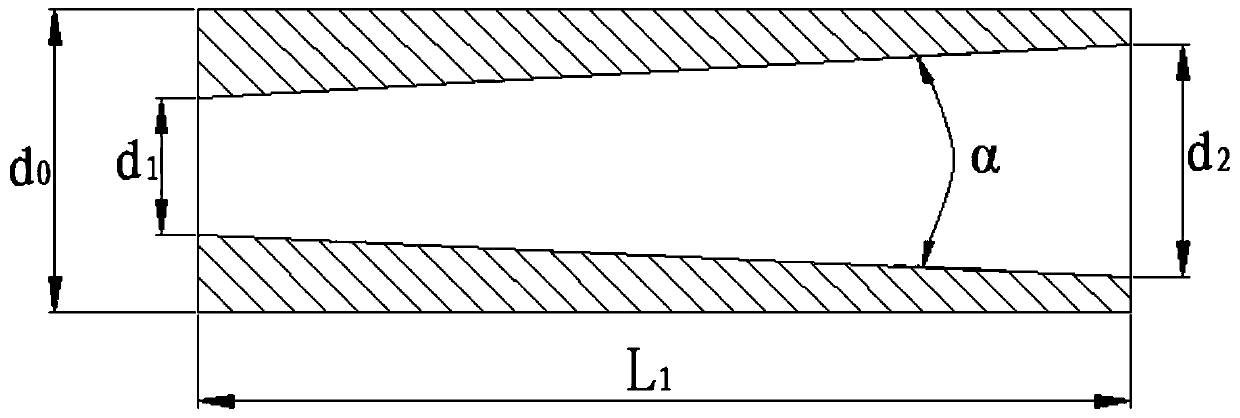

[0033] Step 1, processing T2 red copper into a mandrel, and processing 304 stainless steel into a blind hole outer cylinder; the blind hole of the mandrel and the blind hole outer cylinder has a cone angle of 1°; the length of the blind hole outer cylinder 230mm, the outer diameter is 97mm; the depth of the blind hole is 200mm, the bottom surface diameter is 45mm, the top surface diameter is 48.50mm; the length of the mandrel is 195mm, the diameter of the end face of the mandrel small end is 45mm, mandrel The diameter of the end face of the big end is 48.42mm;

[0034] Step 2. Process 304 stainless steel into a circular plate with a diameter of 97mm and a thickness of 26mm. Place the blind hole outer cylinder obtained in step 1 vertically with the open end upward, and insert the mandrel obtained in step 1 into the blind hole. In the outer cylinder, the circular plate is placed on the top of the blind hole outer cylinder, ...

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] Step 1, processing TU00 oxygen-free copper into a core rod, and processing 4J29 iron-nickel-cobalt glass sealing alloy into a through-hole outer cylinder; the through-hole of the core rod and the through-hole outer cylinder has a cone angle of 3°; The length of the through hole outer cylinder is 200mm, and the outer diameter is 97mm; the diameter of the end face of the through hole small end of the through hole is 45mm, and the diameter of the end face of the through hole big end is 55.50mm; the length of the mandrel is 195mm, The diameter of the end surface of the small end of the mandrel is 45mm, and the diameter of the end surface of the large end of the mandrel is 55.20mm;

[0049] Step 2. Process the 4J29 iron-nickel-cobalt glass sealing alloy into two circular plates with a diameter of 97mm and a thickness of 26mm. Place the through-hole outer cylinder obtained in step 1 vertically on a circular plate with the...

Embodiment 3

[0054] This embodiment includes the following steps:

[0055] Step 1. Process TU00 oxygen-free copper into a mandrel, and process TA1 industrial pure titanium into a through-hole outer cylinder; the through-holes of the mandrel and the through-hole outer cylinder have a cone angle of 5°; the through-hole The length of urceolus is 200mm, outer diameter is 97mm; The diameter of the end face of the through hole small end of described through hole is 45mm, the diameter of the end face of through hole big end is 62.45mm; The length of described mandrel is 195mm, mandrel is small The diameter of the end face of the mandrel is 45mm, and the diameter of the end face of the big end of the mandrel is 62.01mm;

[0056] Step 2. Process TA1 industrial pure titanium into two circular plates with a diameter of 97 mm and a thickness of 26 mm. Place the through-hole outer cylinder obtained in step 1 vertically on a circular plate with the small end of the through hole as the bottom. The obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com