Method for purifying high-residue waste liquid and treatment system

A treatment system and waste liquid technology, applied in chemical instruments and methods, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., to achieve good purification effect, reduce the risk of disease transmission, and improve the effect of microbial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

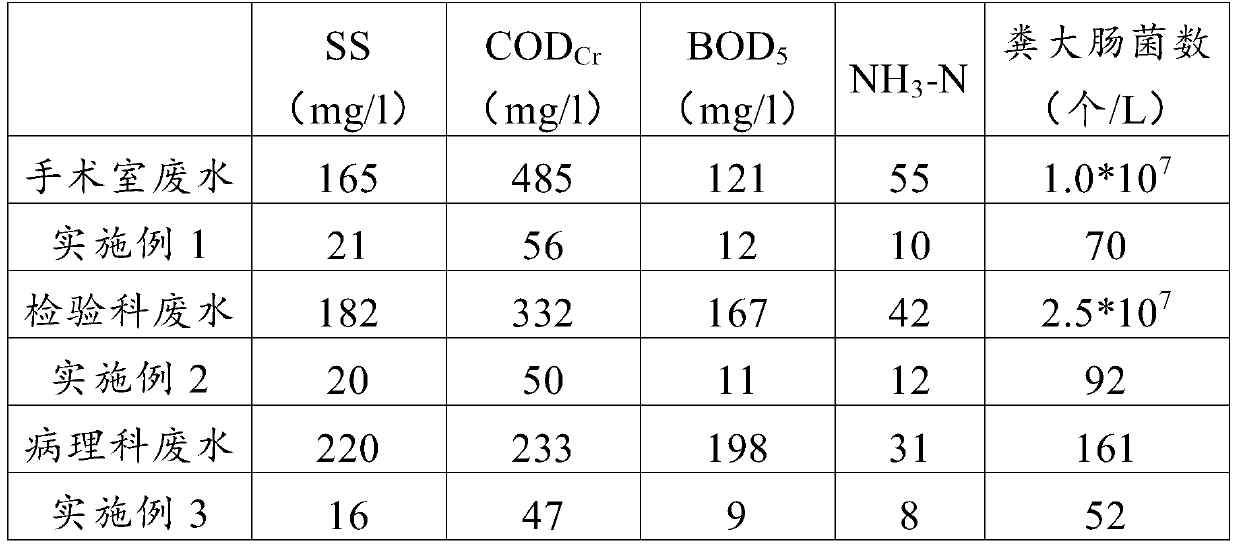

Embodiment 1

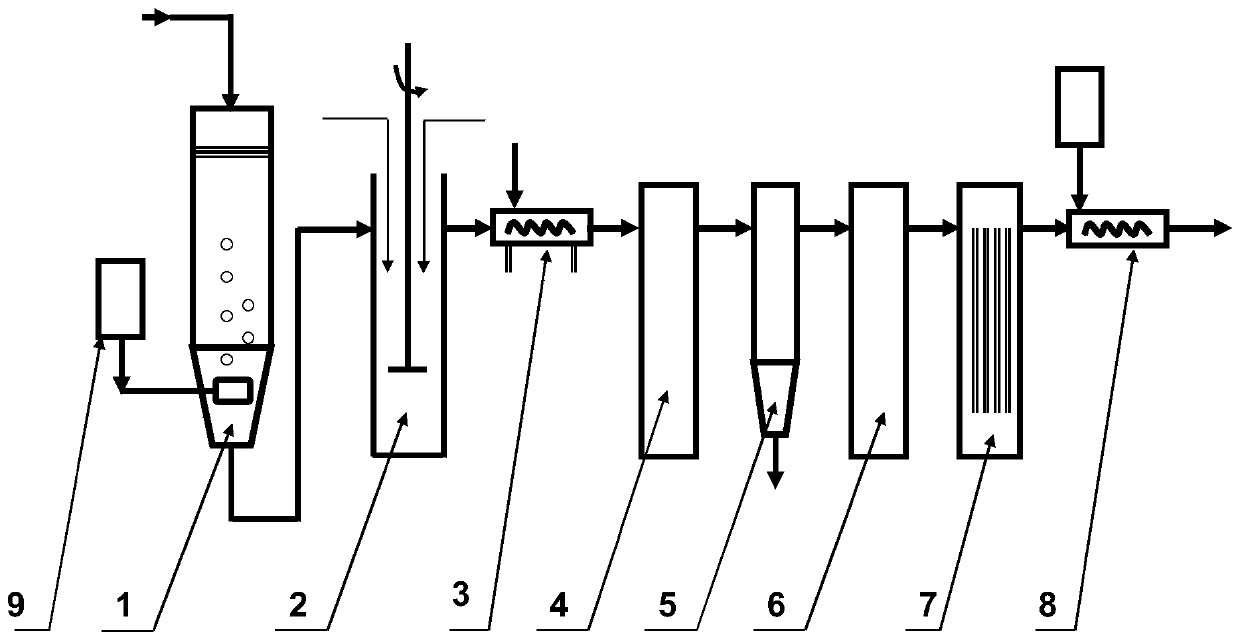

[0051] A method and treatment system for purifying high-residue waste liquid, comprising the following steps,

[0052] Step 1. Collect the high-residual waste liquid (including blood clots, broken tissues, amniotic fluid, meconium, etc.) produced in the obstetrics and gynecology operating room into the waste water collection box. Remove the solid matter contained in the waste water, and then fall into the waste water collection tank. The lower part of the waste water collection tank is in the shape of an inverted cone. A gas distributor connected to an external ozone generating mechanism is arranged inside the inverted cone-shaped part. The ozone flows from the gas distributor. Dispersed in the distribution holes and poured into the waste water collected by the waste water collection tank;

[0053] Step 2, the waste water flowing out from the bottom of the waste water collection tank enters the oxidation pond, and simultaneously adds a composite strong oxidant to the oxidation...

Embodiment 2

[0062] A method and treatment system for purifying high-residue waste liquid, comprising the following steps,

[0063] Step 1. Collect the mixed high-residue waste liquid from the laboratory department (collected by the unified sewage outlet of the laboratory department, including blood samples, urine samples, flushing wastewater, and wastewater containing test reagents) into the wastewater collection tank, and the wastewater first passes through the filter set at the upper end of the wastewater collection tank. Net, filter and remove the solid matter contained in the waste water, and then fall into the waste water collection tank. The lower part of the waste water collection tank is in the shape of an inverted cone, and a gas distributor connected to the external ozone generating mechanism is arranged inside the inverted cone-shaped part. The ozone from the gas Dispersed in the distribution hole of the distributor and poured into the waste water collected in the waste water co...

Embodiment 3

[0072] A method and treatment system for purifying high-residue waste liquid, comprising the following steps,

[0073] Step 1. Collect high-residual waste liquid from the pathology department (collected by the unified sewage outlet of the pathology department, including tissue residues, embedded fragments, flushing wastewater, and wastewater containing fixed reagents) into the wastewater collection tank, and the wastewater is first collected by wastewater The filter net installed at the upper end of the tank filters and removes the solid matter contained in the waste water, and then falls into the waste water collection tank. The lower part of the waste water collection tank is in the shape of an inverted cone, and a gas distribution channel connected to the external ozone generating mechanism is arranged inside the inverted cone. The ozone is diffused from the distribution hole of the gas distributor and poured into the wastewater collected by the wastewater collection tank; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com