Method for preparing ceramsite by utilizing stale garbage

A rubbish and antiquated technology, applied in applications, household utensils, clay products, etc., can solve problems such as environmental heat pollution, restricted promotion, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

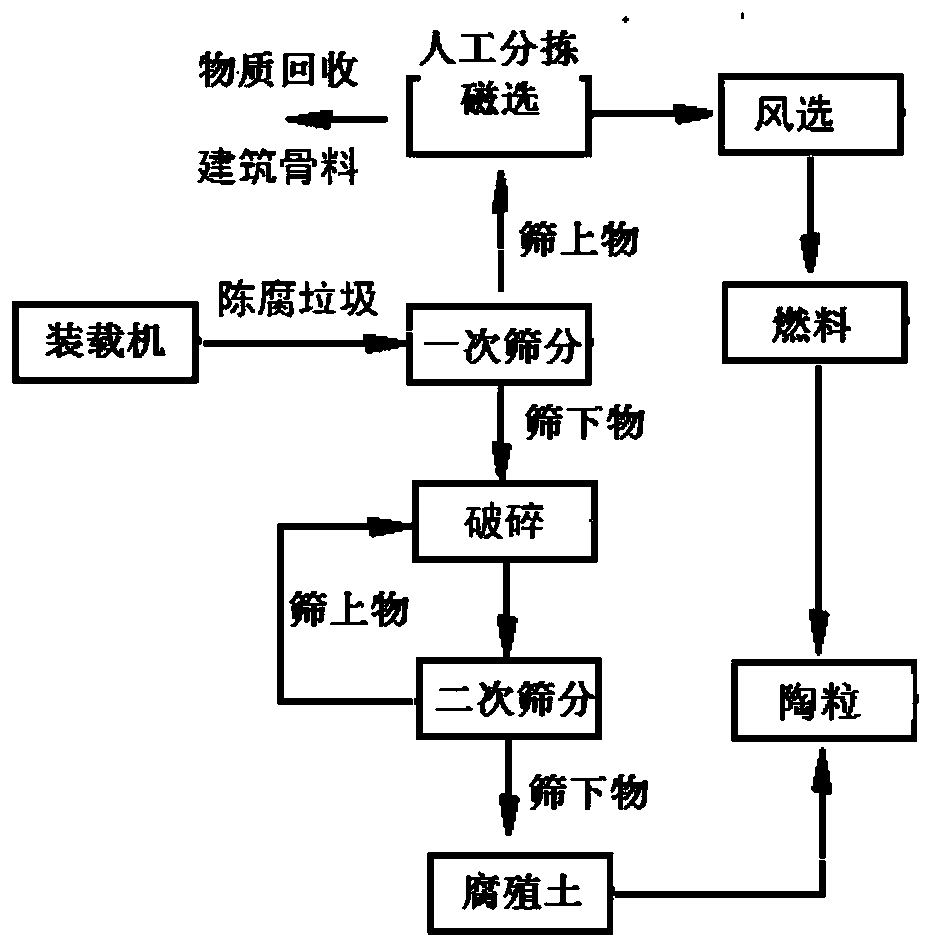

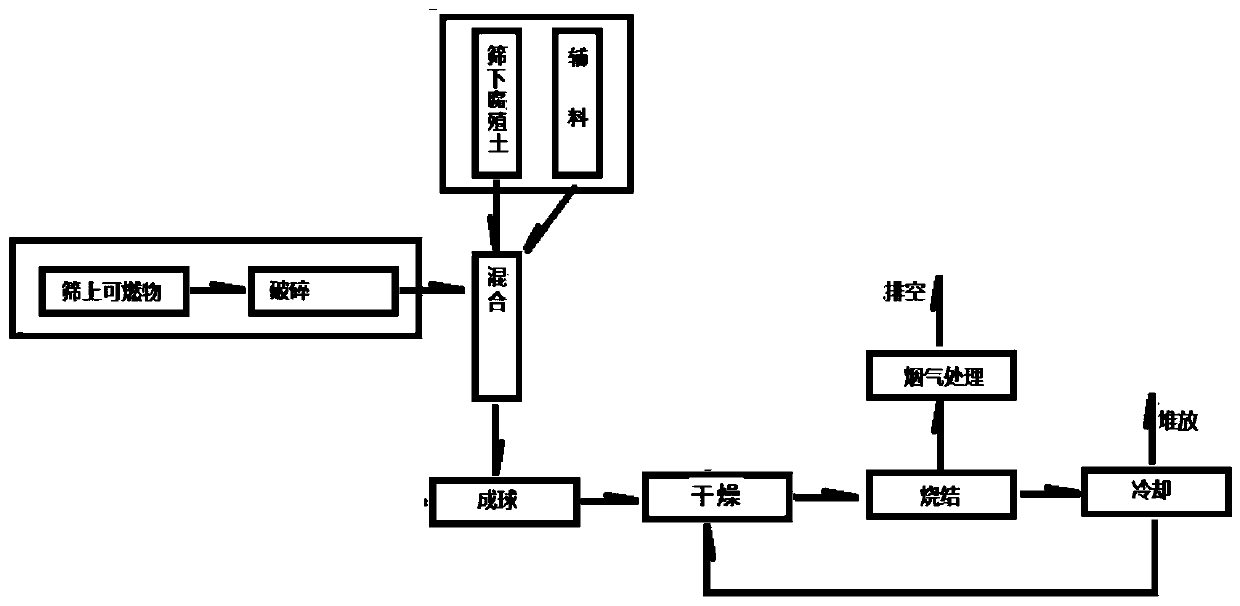

Method used

Image

Examples

specific Embodiment

[0049] In the present embodiment, the rubbish in the area is constituted as follows: the weight of the oversieve is 12% of the gross rubbish, and the weight of the humus soil is 60% of the gross rubbish, which is now calculated as a pile of rubbish with a gross weight of 100 kg Base: industrial rotary kiln for the production of ceramsite, the temperature is 1200 ℃.

[0050] After sieving 100 kilograms of stale garbage, 60 kilograms of humus can be obtained. If 20% of auxiliary materials need to be added, the total weight of materials that can be used to make ceramsite: 60×1.2=72kg.

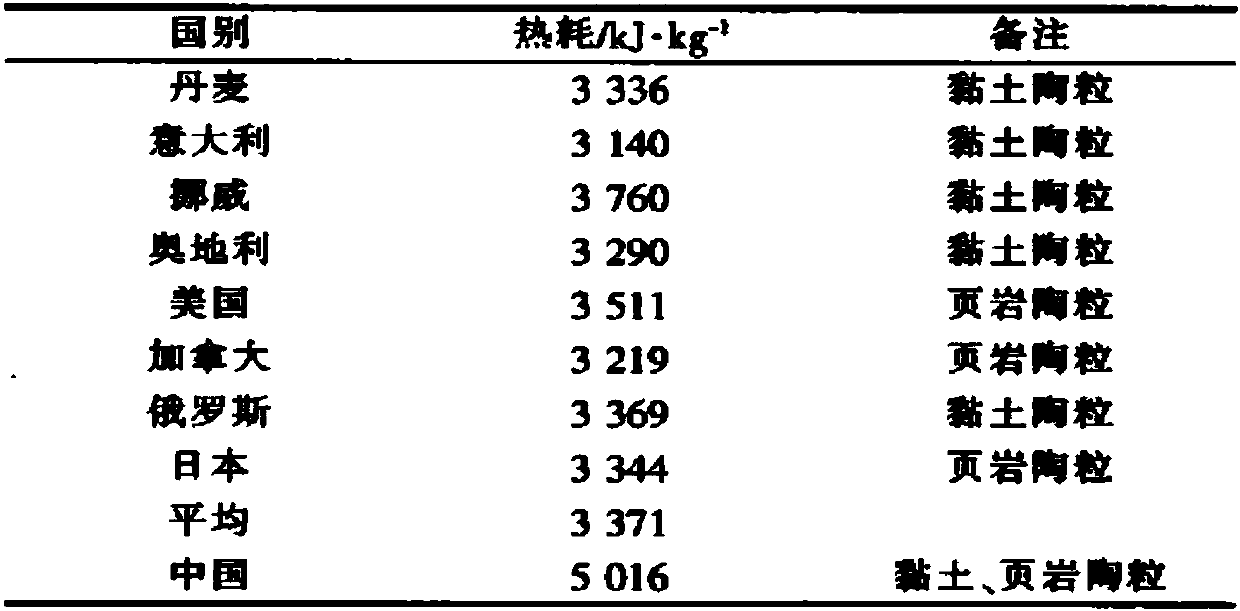

[0051] The heat required in the production process of ceramsite can be seen in Table 1.

[0052] It can be seen that if all of them are used to make ceramsite, the required heat is: 72×5000=3.6×10 5 kJ.

[0053] According to statistics, the calorific value of humus soil is 1533kJ / kg, and the heat it can provide is: 1533×75=1.15×10 3 kJ.

[0054] After sieving, the total weight of light combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com