A kind of nearly isothermal forging method of tial alloy

An isothermal forging and alloying technology, which is applied in the field of intermetallic compound forging, can solve the problems of lack of α-solidified TiAl alloy forging process and uneven structure, and achieve the effect of fine structure, good structure uniformity and reduced forging cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

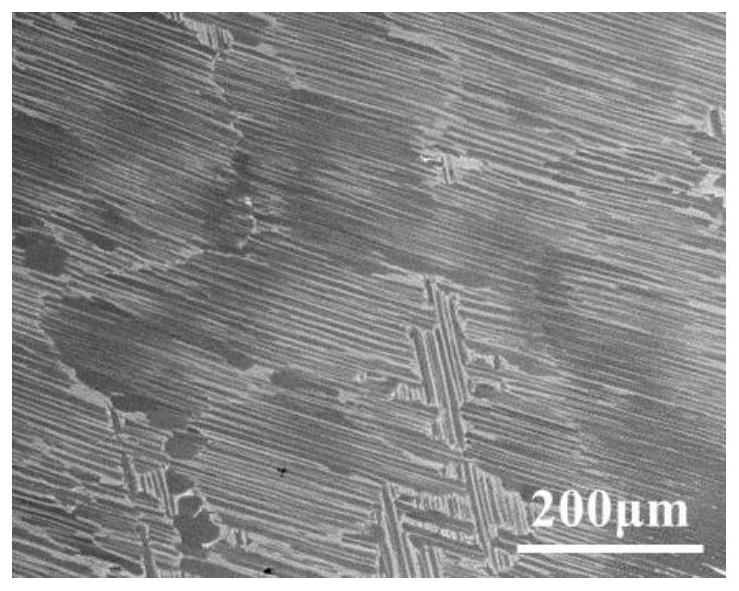

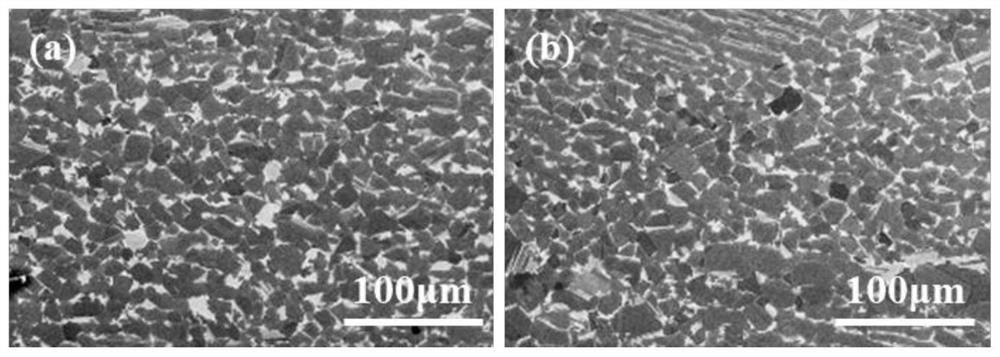

[0034] The TiAl alloy ingot used in this embodiment is an alloy ingot with a nominal composition of Ti-48Al-2Cr-2Nb, wherein the composition is an atomic percentage, and the ingot size used is Φ90×150 mm.

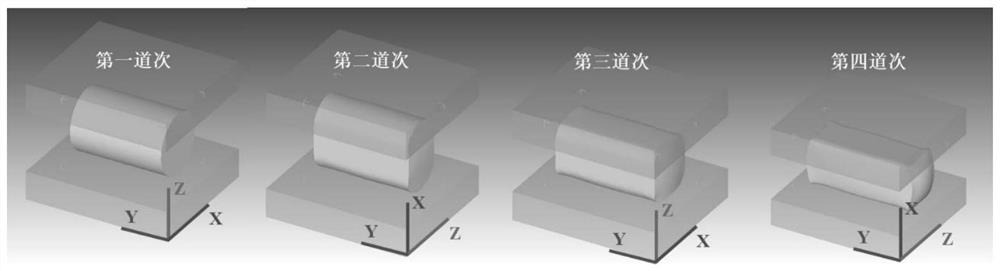

[0035] The TiAl alloy near-isothermal forging method of the present embodiment comprises:

[0036] Step 1: Preparation before forging: After the hot isostatic pressing of the ingot, wire cutting + machining is used to cut the ingot to be die-cast with a smooth surface, no obvious cracks, wire cutting marks, turning tool marks and positioning holes, etc., the size of the ingot Φ90×150mm; then, put the ingot into a Q235 sheath with a wall thickness of 5mm (air holes are opened on the end cap of the sheath), and fill the 3mm gap between the ingot and the sheath wall with high-temperature asbestos, and finally use argon arc Weld the end cap of the sheath to the wall of the sheath;

[0037] Step 2: Heating the ingot and indenter: Put the packaged ingot into a box furnace and he...

Embodiment 2

[0045] The TiAl alloy described in this embodiment is an alloy ingot with a nominal composition of Ti-48Al-2Cr-2Nb, wherein the composition is an atomic percentage, and the size of the ingot used is Φ90×150 mm.

[0046] The TiAl alloy near-isothermal forging method of the present embodiment comprises:

[0047] Step 1: Preparation before forging: After the hot isostatic pressing of the ingot, wire cutting + machining is used to cut the ingot to be die-cast with a smooth surface, no obvious cracks, wire cutting marks, turning tool marks and positioning holes, etc., the size of the ingot Φ90×150mm; then, put the ingot into a Q235 sheath with a wall thickness of 5mm (air holes are opened on the end cap of the sheath), and fill the 3mm gap between the ingot and the sheath wall with high-temperature asbestos, and finally use argon arc Weld the end cap of the sheath to the wall of the sheath;

[0048] Step 2: Heating the ingot and indenter: Put the packaged ingot into a box furnace ...

Embodiment 3

[0056] The TiAl alloy described in this embodiment is an alloy ingot with a nominal composition of Ti-48Al-2Cr-2Nb, wherein the composition is an atomic percentage, and the size of the ingot used is Φ90×150 mm.

[0057] The TiAl alloy near-isothermal forging method of the present embodiment comprises:

[0058] Step 1: Preparation before forging: After the hot isostatic pressing of the ingot, wire cutting + machining is used to cut the ingot to be die-cast with a smooth surface, no obvious cracks, wire cutting marks, turning tool marks and positioning holes, etc., the size of the ingot Φ90×150mm; then, put the ingot into a Q235 sheath with a wall thickness of 5mm (air holes are opened on the end cap of the sheath), and fill the 3mm gap between the ingot and the sheath wall with high-temperature asbestos, and finally use argon arc Weld the end cap of the sheath to the wall of the sheath;

[0059] Step 2: Heating the ingot and indenter: Put the packaged ingot into a box furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com