E-type magnetic core grinding and processing equipment

A technology of grinding processing and magnetic core, which is applied in the direction of metal processing equipment, grinding tools, grinding/polishing equipment, etc., and can solve the problems of affecting the filtering effect of the filter and the entry of iron filings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

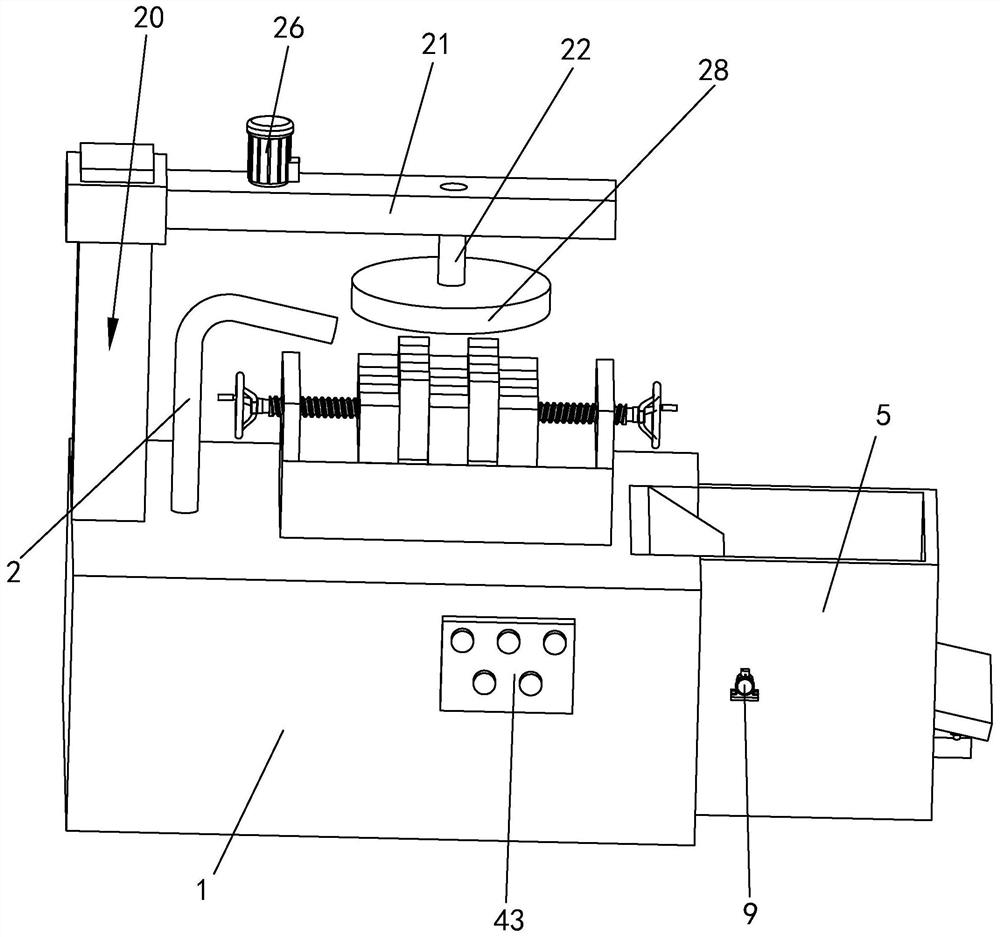

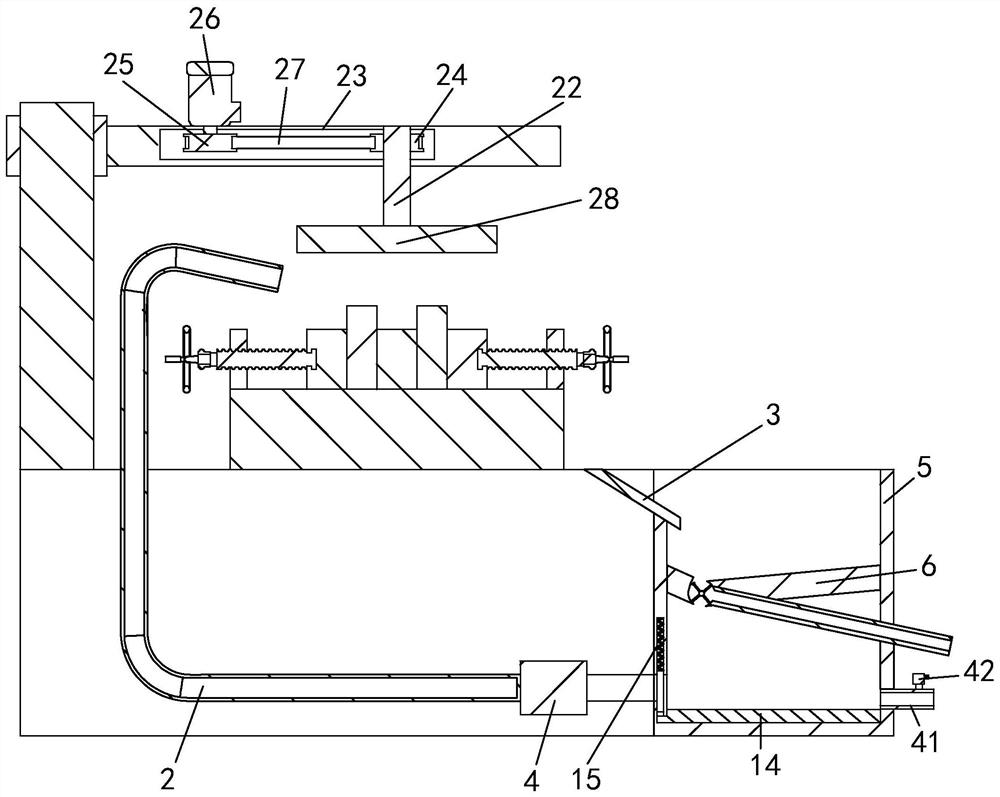

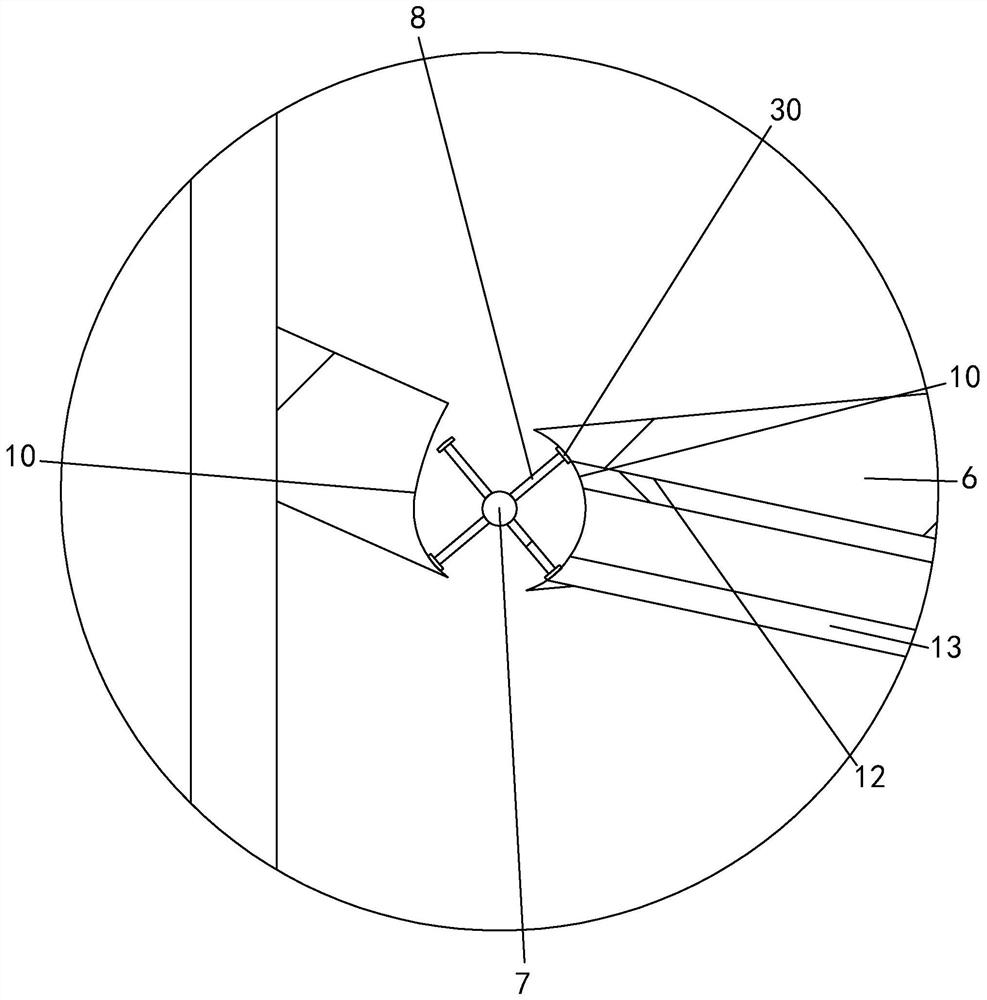

[0026] See figure 1 , figure 2 and Figure 4 As shown, an E-type magnetic core grinding and processing equipment includes a workbench 1, a grinding mechanism arranged on one side of the workbench 1 that can be lifted up and down, and a device that is arranged on the workbench 1 to clamp and fix the E-type magnetic core. Clamping mechanism, the water guide pipe 2 penetrating and fixed on the upper end surface of the workbench 1, and the water st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com