Preparation method of diindolylmethanecompound

An indolylmethane and compound technology, which is applied in the field of preparation of bis-indolylmethane compounds, can solve the problems of poor atom economy, pollution, and difficulty in large-scale application, achieves efficient and clean production, reduces use costs, and saves The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

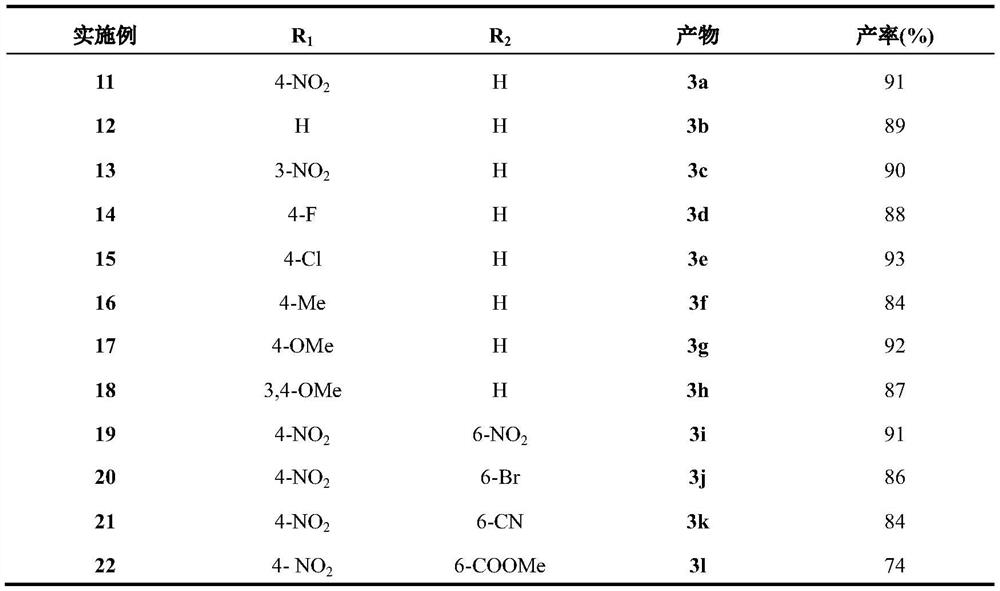

Examples

Embodiment 1

[0019] P-Nitrobenzaldehyde (0.25mmol, 0.0418g) and indole (0.5mmol, 0.0585g) were respectively added into a pressure-resistant closed hydrothermal reaction kettle with a volume of 10 ml, and placed in a heater. Infrared measurement of the reactor temperature from room temperature to 160 ° C, and at this temperature to keep heating for 1 hour, stop heating; after the temperature of the reactor is reduced to room temperature (about 25 ° C), the reactor is opened, and by TLC thin layer chromatography ( The volume ratio is petroleum ether: ethyl acetate 3:1 (solvent is the developing agent) to track and monitor the reaction results. After initially confirming that the reaction is basically tending to completion, add dichloromethane (5mL×2) in batches and stir to disperse, then transfer Suction filtration in a suction filtration device, washing to dryness is the target product, and the product yield is 90%; the collected dichloroethane mother liquor is evaporated to recover the solv...

Embodiment 2

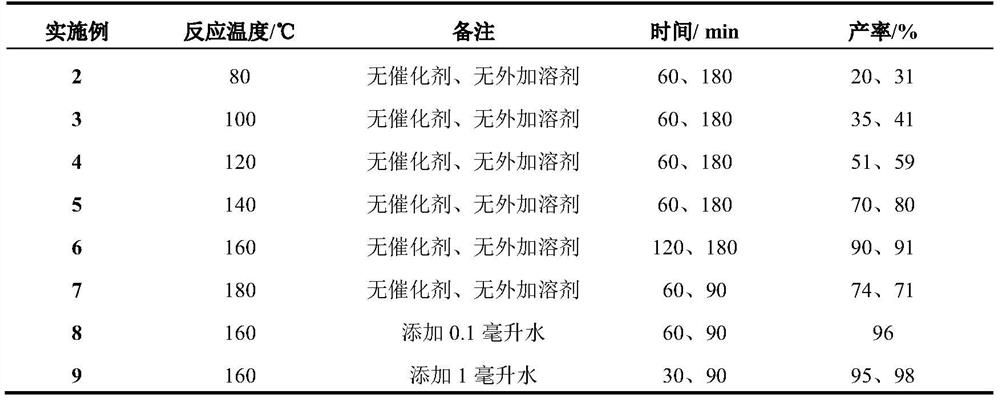

[0021] The feed ratio and the feed amount of the reaction substrate, the reaction vessel, and the basic operation process are the same as in Example 1, except that a small amount of water is added, and the temperature and time of the reaction are changed, and the yield results of the follow-up monitoring reaction are shown in Table 1. The results show that the addition of a small amount of water has an obvious thermodynamic catalytic effect at a temperature of 160-180°C.

[0022]

[0023] The influence result of table 1 temperature of reaction on reaction product yield

Embodiment 3

[0025] Add p-nitrobenzaldehyde (1 mol, 16.713 g), indole (2 mol, 23.430 g), and 8 ml of water respectively into a pressure-resistant closed reactor with a volume of 1 liter, and place it in a heater. Measure the temperature of the reactor by infrared rays from room temperature to 160°C, and keep heating at this temperature for 1 hour, then stop heating; after the temperature of the reactor drops to room temperature (about 25°C), open the reactor and take out the solid material in the reactor In an open container of 1 liter, and by TLC thin layer chromatography (volume ratio is sherwood oil: the solvent of ethyl acetate 3:1 is developing agent) follow-up monitoring reaction result, the content of preliminarily confirmed reaction product is close to 98%. Then, in the container containing the crude product, dichloromethane (300mL × 3) was added in batches, and after stirring and dispersing, it was transferred to a suction filtration device for suction filtration and washing to dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com