Ethylene propylene rubber, raw material composition of ethylene propylene rubber, lifting lug and preparation method and application of lifting lug

A raw material composition, ethylene-propylene rubber technology, applied in the field of ethylene-propylene rubber and its raw material composition, can solve the problems of poor NVH control, insufficient high temperature resistance, insufficient service life, etc., and achieves excellent control efficiency, low cost, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5、 comparative example 1 and comparative example 2

[0099] Table 1

[0100]

[0101]

[0102] "-" in Table 1 indicates that the number of parts is "0"; the Mooney viscosity refers to the Mooney viscosity ML125°C 1+4.

[0103] Example 1-5

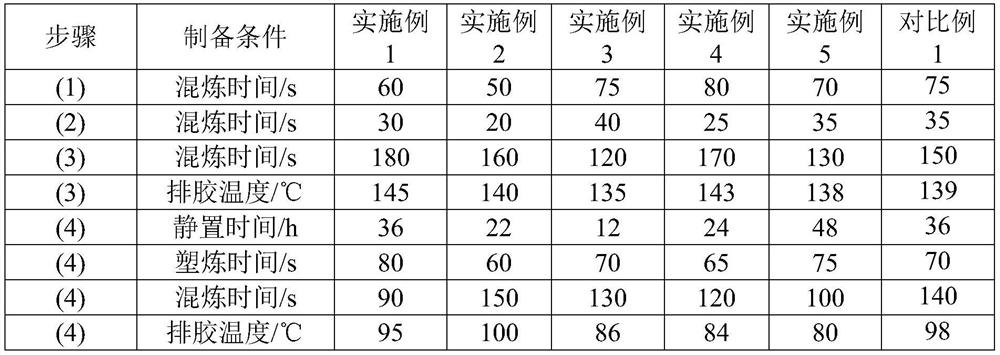

[0104] The raw material components of each embodiment in Table 1 are obtained according to the following preparation steps to obtain the ethylene-propylene rubber of each embodiment (the parameters of each specific step are as shown in Table 2):

[0105] (1) Put ethylene-propylene rubber A and ethylene-propylene rubber B into an internal mixer and mix to obtain mixture A;

[0106] (2) Continue to drop zinc oxide, magnesium oxide, stearic acid, anti-aging agent, polyethylene glycol and silane coupling agent into the internal mixer, and knead to obtain mixture B;

[0107] (3) continue to drop into internal mixer carbon black, precipitated white carbon black and plasticizer, through mixing, debinding and sheeting, get rubber premix;

[0108] (4) The rubber premix is left to stand, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com