Polyimide/multi-walled carbon nanotube/nano ferroferric oxide composite aerogel and preparation method thereof

A technology of multi-walled carbon nanotubes and composite airgel, which is applied in the field of composite materials, and achieves the effects of simple preparation method, good application prospect and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

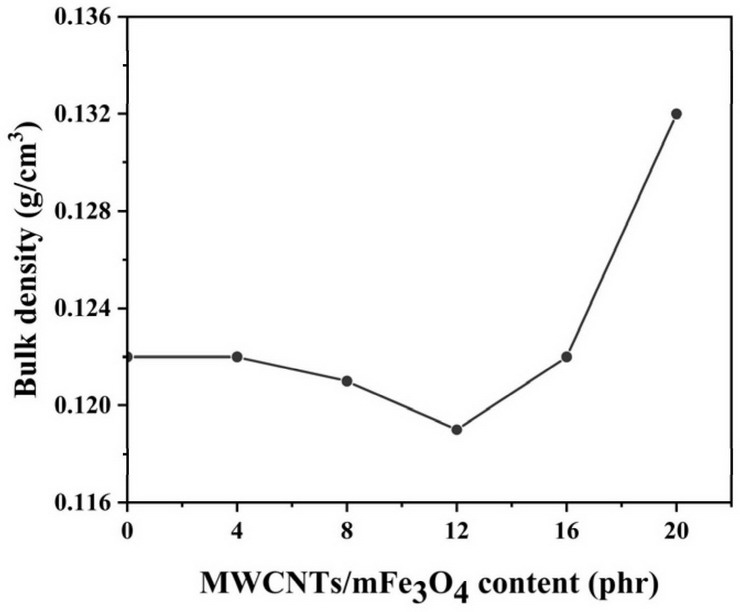

[0049] Example 1: Preparation of composite airgel PI / MWCNTs-COOH / mFe 3 o 4 (100 / 10 / 10)

[0050] The specific steps for preparing polyimide / multi-walled carbon nanotubes / nano ferric oxide composite airgel are as follows:

[0051] 1. Preparation of ammonium citrate modified nano Fe 3 o 4 (mFe 3 o 4 )

[0052] Add 4g of nanometer iron ferric oxide particles into 200mL of ammonium citrate aqueous solution (concentration of ammonium citrate solution is 1M), mechanically stir for 5min, then ultrasonically disperse for 60min, and then keep warm at 60°C for 12h, stirring once every 30min. Separate the phases of the system, remove the supernatant in the system, and wash the remaining part with acetone several times until the color of the acetone lotion changes from milky white to clear, and then dry the obtained solid at 60°C for 2 hours to obtain ammonium citrate modified Nano Fe 3 o 4 , hereinafter referred to as mFe 3 o 4 .

[0053] 2. Prepare polyamic acid ammonium salt...

Embodiment 2

[0058] Example 2: Preparation of composite airgel PI / MWCNTs-COOH / mFe 3 o 4 (100 / 9 / 9)

[0059] Using the same preparation method as in Example 1, the only difference is that the input amount of MWCNTs-COOH in step (2.2) is modified from 1g to 0.9g, TNMDIS is modified to 0.45g, mFe 3 o4 The input amount was changed from 1g to 0.9g, and PAA, MWCNTs-COOH, mFe 3 o 4 Composite airgel PI / MWCNTs-COOH / mFe with a weight ratio of 100:9:9 3 o 4 (100 / 9 / 9).

Embodiment 3

[0060] Example 3: Preparation of composite airgel PI / MWCNTs-COOH / mFe 3 o 4 (100 / 8 / 8)

[0061] Using the same preparation method as in Example 1, the only difference is that the input amount of MWCNTs-COOH in step (2.2) is modified from 1g to 0.8g, TNMDIS is modified to 0.4g, mFe 3 o 4 The input amount was changed from 1g to 0.8g, and PAA, MWCNTs-COOH, mFe 3 o 4 Composite airgel PI / MWCNTs-COOH / mFe with a weight ratio of 100:8:8 3 o 4 (100 / 8 / 8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com