A kind of robot rv reducer grease and preparation method thereof

A technology of reducer and lubricating grease, which is applied in the field of lubricating grease for robot RV reducer and its preparation, can solve the problems of inability to lubricate, poor extrusion wear resistance, easy softening and loss, etc., and achieve good high temperature stability and Oxidation stability, good low-temperature performance, and the effect of avoiding softening and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This example prepares the robotic RV reducer grease as follows:

[0024] Step 1. Put 50% of the base oil and fatty acid into the saponification kettle, stir and heat to 75°C, until the fatty acid is completely dissolved;

[0025] Step 2: Add lithium hydroxide aqueous solution, control the saponification temperature at 95°C, and control the saponification time for 2h; after the saponification is completed, continue to heat up to 140°C, stir for 20min, then heat up to 205°C for high-temperature refining, and keep the temperature for 5min;

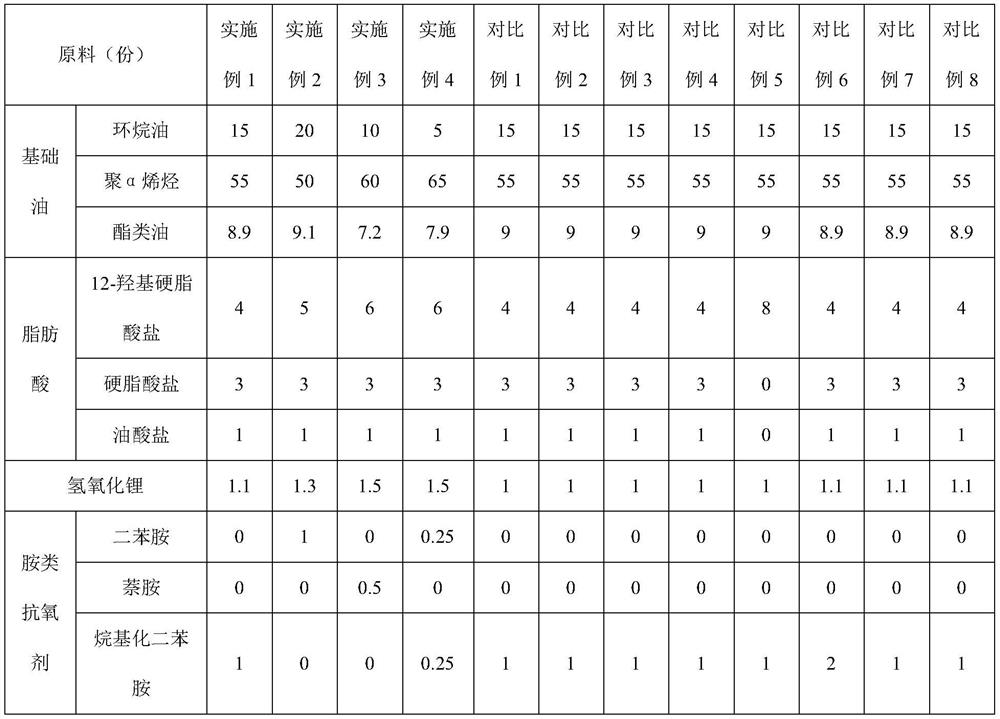

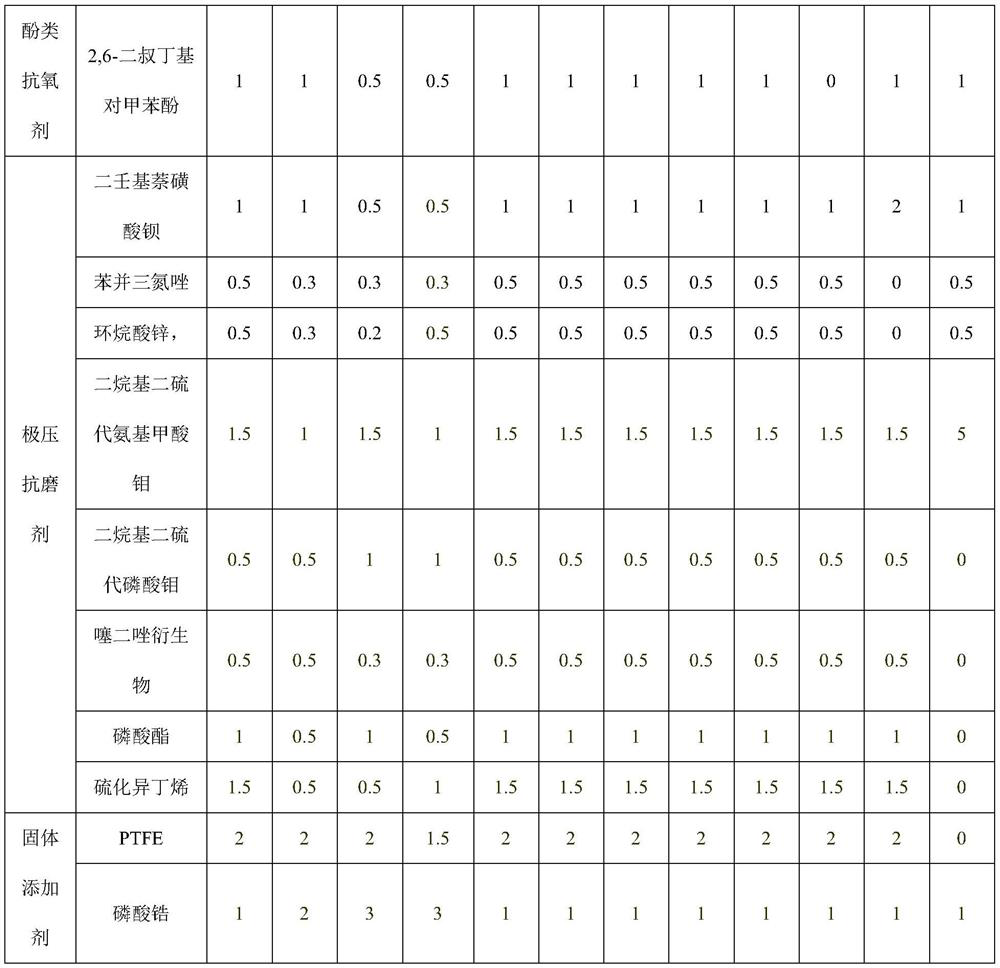

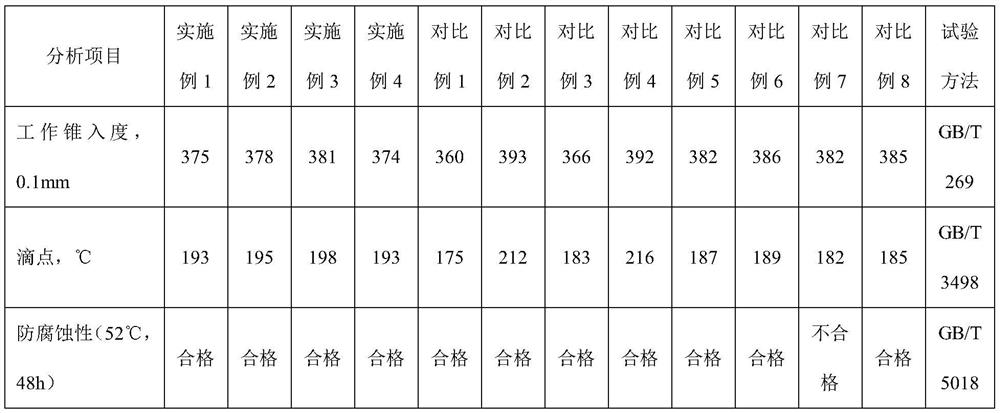

[0026] Step 3: Add the remaining base oil, quench to 165°C, turn the kettle, circulate and filter, cool down to 110°C, add antioxidants, antirust agents, extreme pressure antiwear agents and solid additives after homogenization, stir evenly, remove The finished product is obtained after gasification, and the addition ratio of each raw material component is shown in Table 1.

Embodiment 2

[0028] This example prepares the robotic RV reducer grease as follows:

[0029] Step 1. Put 50% of the base oil and fatty acid into the saponification kettle, stir and heat to 85°C, until the fatty acid is completely dissolved;

[0030] Step 2: Add lithium hydroxide aqueous solution, control the saponification temperature at 105°C, and control the saponification time for 2.5h; after the saponification is completed, continue to heat up to 150°C, stir for 30 minutes, and then heat up to 210°C for high-temperature refining, and keep the temperature for 10 minutes;

[0031] Step 3: Add the remaining base oil, quench to 175°C, turn the kettle, circulate and filter, cool down to 120°C, add antioxidants, antirust agents, extreme pressure antiwear agents and solid additives after homogenization, stir evenly, remove The finished product is obtained after gasification, and the addition ratio of each raw material component is shown in Table 1.

Embodiment 3

[0033] This example prepares the robotic RV reducer grease as follows:

[0034] Step 1. Put 60% of the base oil and fatty acid into the saponification kettle, stir and heat to 80°C, until the fatty acid is completely dissolved;

[0035] Step 2: Add lithium hydroxide aqueous solution, control the saponification temperature at 100°C, and control the saponification time for 2.2h; after the saponification is completed, continue to heat up to 145°C, stir for 25min, then heat up to 208°C for high-temperature refining, and keep the temperature for 8min;

[0036] Step 3: Add the remaining base oil, quench to 170°C, turn the kettle, circulate and filter, cool down to 115°C, add antioxidants, rust inhibitors, extreme pressure antiwear agents and solid additives after homogenization, stir evenly, remove The finished product is obtained after gasification, and the addition ratio of each raw material component is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com