Controlled-release magnetic ZnAlCe hydrotalcite loaded 2-mercaptobenzothiazole corrosion inhibitor and preparation method thereof

A technology of mercaptobenzothiazole and hydrotalcite, which is applied in the field of corrosion inhibitors for seawater circulating cooling systems, can solve problems such as corrosion of metal equipment and environmental pollution by corrosion inhibitors, and achieve targeted positioning, rapid recovery performance, long-term The effect of good corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

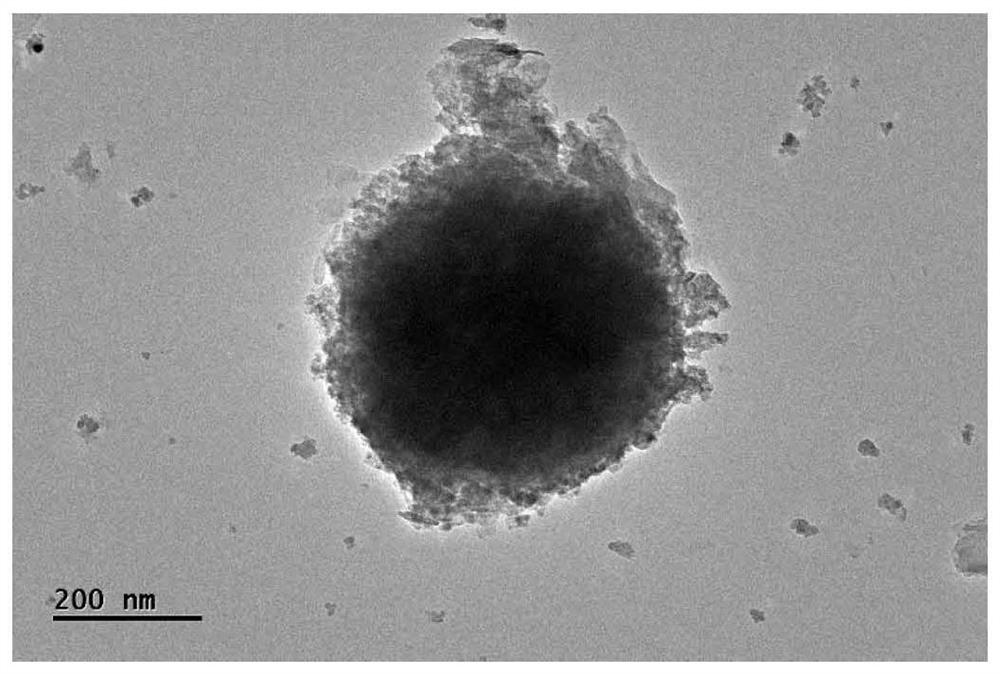

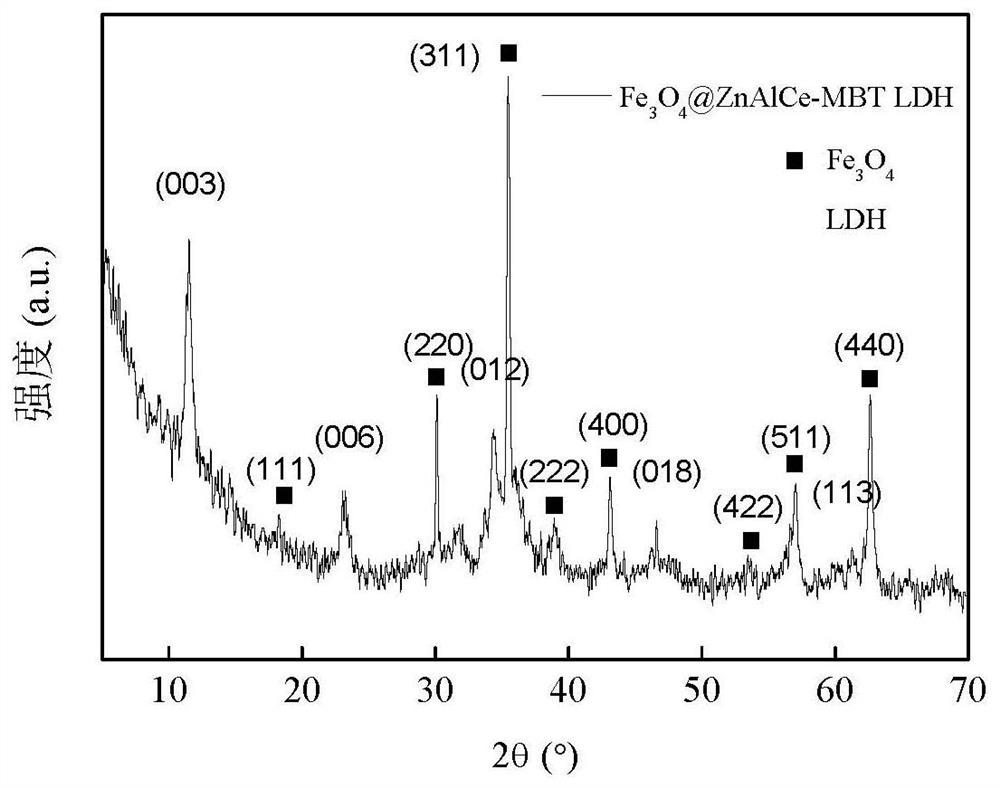

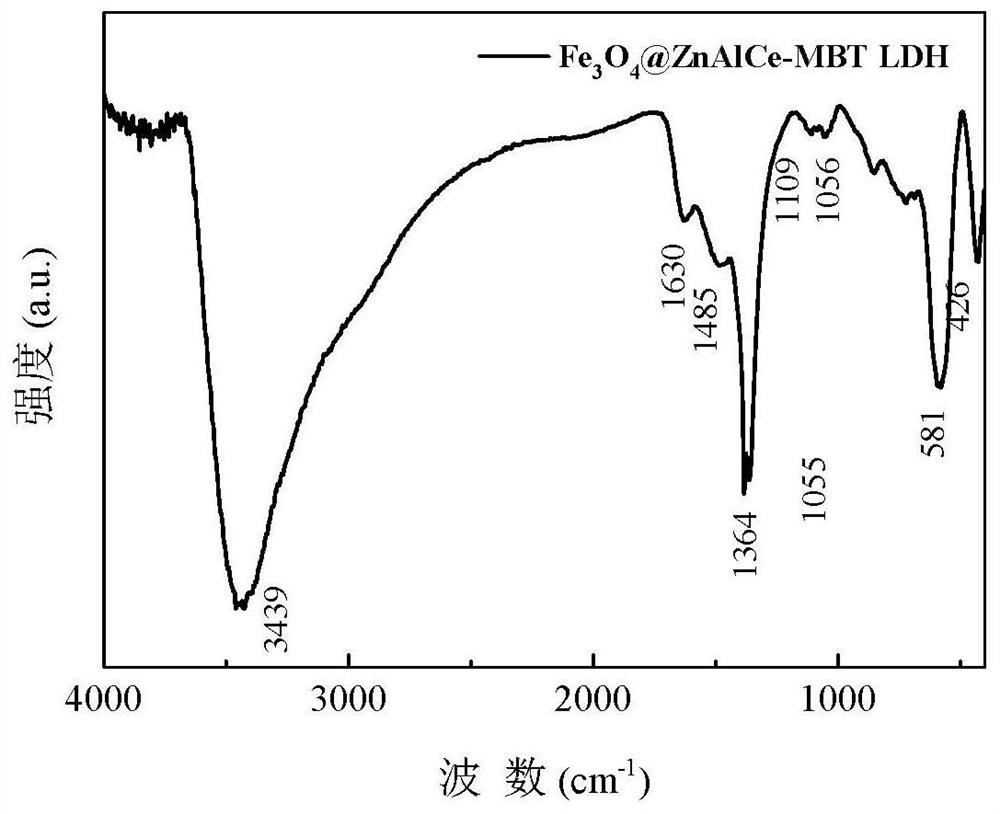

[0043] (1) Weigh 2.7g FeCl 3 ·6H 2 O, 7.2 g CH 3 COONa·3H 2 O, dissolved in 60ml of ethylene glycol, stirred to form a uniform yellow solution, then transferred to an autoclave, and the autoclave was placed in a dry oven at 160°C for 18 hours. The obtained product was separated with a RuFeB permanent magnet, washed repeatedly with deionized water and ethanol, dried in a drying oven at 60°C for 24 hours, and ground to obtain Fe 3 o 4 .

[0044] (2) Weigh 0.174g Fe 3 o 4 Disperse in 100ml of methanol and sonicate for 15min to obtain a uniform suspension. The suspension was transferred to a four-neck flask, stirred at room temperature, and N was continuously fed during the stirring process. 2 .

[0045] (3) Press n(Zn 2+ ) / n(Fe 3 o 4 )=2.0 ratio to weigh Zn(NO 3 ) 2 ·6H 2 O, press n(Zn 2+ ) / n(Al 3+ )=4:1 ratio, n(Al 3+ ) / n(Ce 3+ )=5:1 ratio to weigh Al(NO 3 ) 3 9H 2 O and Ce(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and Ce(NO 3 ) 3 ...

Embodiment 2

[0055] (1) Weigh 2.7g FeCl 3 ·6H 2 O, 7.2 g CH 3 COONa·3H 2 O, dissolved in 60ml of ethylene glycol, stirred to form a uniform yellow solution, then transferred to an autoclave, and the autoclave was placed in a dry oven at 200°C for 16 hours. The obtained product was separated with a RuFeB permanent magnet, washed repeatedly with deionized water and ethanol, dried in a drying oven at 60°C for 24 hours, and ground to obtain Fe 3 o 4 .

[0056] (2) Weigh 0.174g Fe 3 o 4 Disperse in 100ml of methanol and sonicate for 15min to obtain a uniform suspension. The suspension was transferred to a four-neck flask, stirred at room temperature, and N was continuously fed during the stirring process. 2 .

[0057] (3) Press n(Zn 2+ ) / n(Fe 3 o 4 )=10.0 ratio to weigh Zn(NO 3 ) 2 ·6H 2 O, press n(Zn 2+ ) / n(Al 3+ )=2:1, the ratio of n(Al 3+ ) / n(Ce 3+ )=6:1 ratio to weigh Al(NO 3 ) 3 9H 2 O and Ce(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and Ce(NO ...

Embodiment 3

[0063] (1) Weigh 2.7g FeCl 3 ·6H 2 O, 7.2 g CH 3 COONa·3H 2 O, dissolved in 60ml of ethylene glycol, stirred to form a homogeneous yellow solution, then transferred to an autoclave, and the autoclave was placed in a 180°C drying oven to react for 14h. The obtained product was separated with a RuFeB permanent magnet, washed repeatedly with deionized water and ethanol, dried in a drying oven at 60°C for 24 hours, and ground to obtain Fe 3 o 4 .

[0064] (2) Weigh 0.174g Fe 3 o 4 Disperse in 100ml of methanol and sonicate for 15min to obtain a uniform suspension. The suspension was transferred to a four-neck flask, stirred at room temperature, and N was continuously fed during the stirring process. 2 .

[0065] (3) Press n(Zn 2+) / n(Fe 3 o 4 )=5.0 ratio to weigh Zn(NO 3 ) 2 ·6H 2 O, press n(Zn 2+ ) / n(Al 3+ )=5:1 ratio, n(Al 3+ ) / n(Ce 3+ )=7:1 ratio to weigh Al(NO 3 ) 3 9H 2 O and Ce(NO 3 ) 3 9H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O and Ce(NO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com