Large-size plate forming online measurement system and method based on machine vision

A sheet metal forming and measuring system technology, used in measuring devices, instruments, optical devices, etc., can solve the problems of good software algorithm robustness, small measurement range, low efficiency, etc., to improve measurement accuracy, fast running speed, The effect of increasing the measuring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

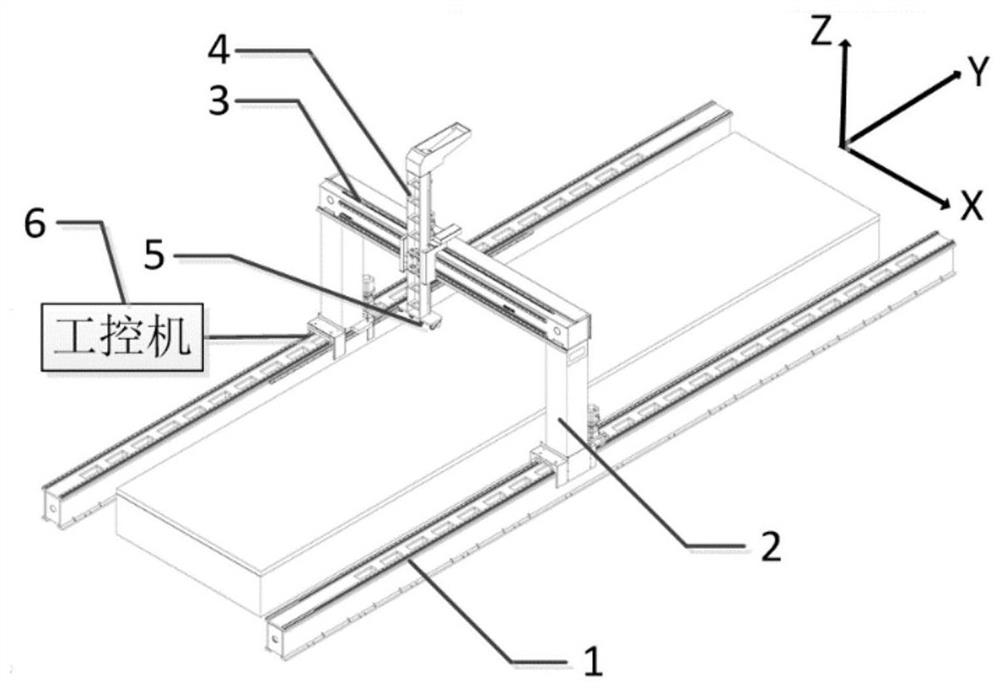

[0047] A machine vision-based online measurement system and method for large-size sheet metal forming of the present invention, such as figure 1 As shown, it includes slide rails, side supports, beams, sensor brackets, three-dimensional displacement sensors, motion control systems, industrial computers and steel plate workpieces to be tested.

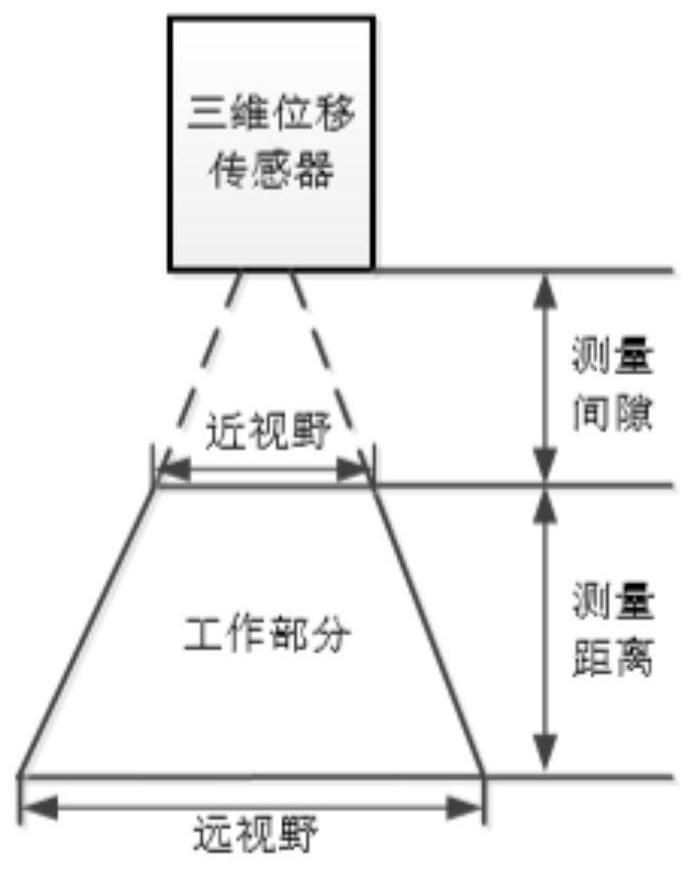

[0048] When measuring, the steel plate workpiece to be tested is placed under the three-dimensional displacement sensor, and the maximum width measurement of 2500mm can be realized through the splicing of the X-direction measurement data of multiple sensors, and the maximum 12000mm can be realized through the movement of the side support and the beam in the Y direction. For length measurement, the maximum height measured by the sensor is 725mm, and direct sunlight should be avoided during the measurement process.

[0049] Due to the large size of the workpiece to be measured, the present invention adopts the method of moving the camera ...

Embodiment 2

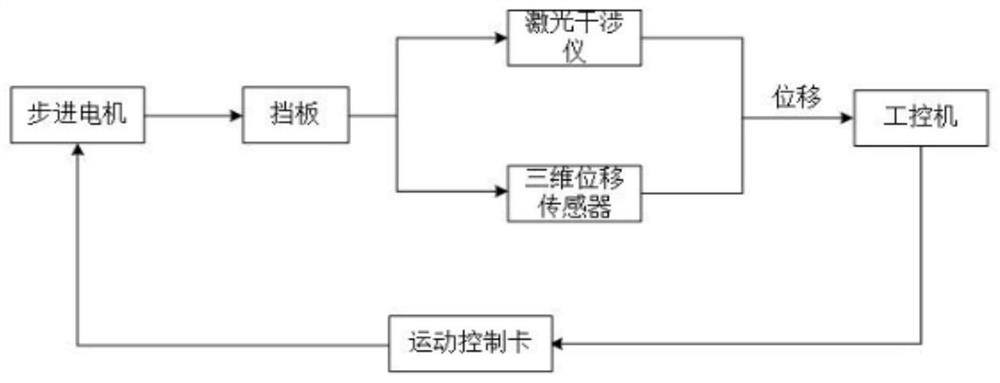

[0059] The large-size plate forming online measurement method in this embodiment includes a laser interferometer-based three-dimensional displacement sensor calibration algorithm, a three-dimensional point cloud data splicing algorithm, a three-dimensional point cloud data preprocessing algorithm, a three-dimensional point cloud data segmentation algorithm, model reconstruction and Surface fitting.

[0060] The algorithm for calibrating the three-dimensional displacement sensor based on the laser interferometer is specifically: the industrial computer drives the stepper motor to move through the motion control card, the stepper motor controls the movement of the baffle through the corresponding transmission mechanism, and the laser interferometer and the three-dimensional displacement sensor simultaneously collect The moving distance of the baffle, the data measured by the laser interferometer are used as the standard input of the calibration system, the data measured by the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com