Cold drying instant soup and production technology thereof

A production process and technology for soup, applied in food science, synchronization device, bottle filling, etc., can solve the problems of cold-dry instant soup requiring manual assistance, overfilling, low production efficiency, etc., to achieve uniform particle size, Avoid leakage, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

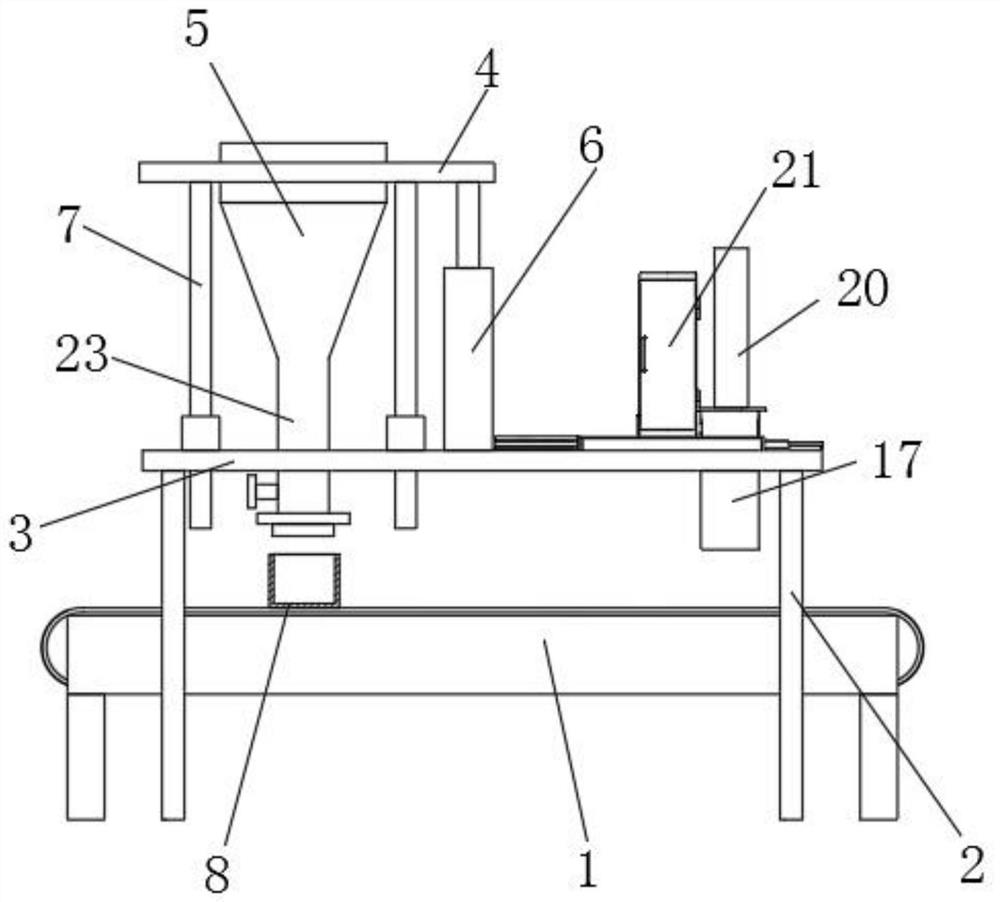

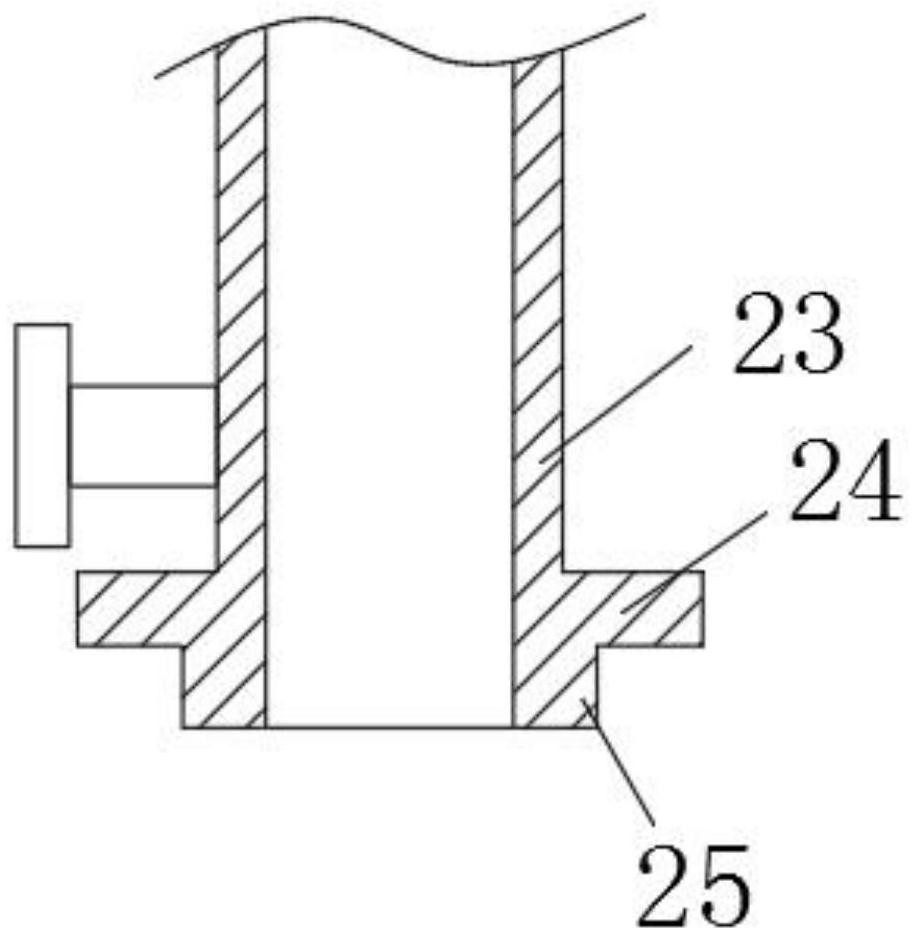

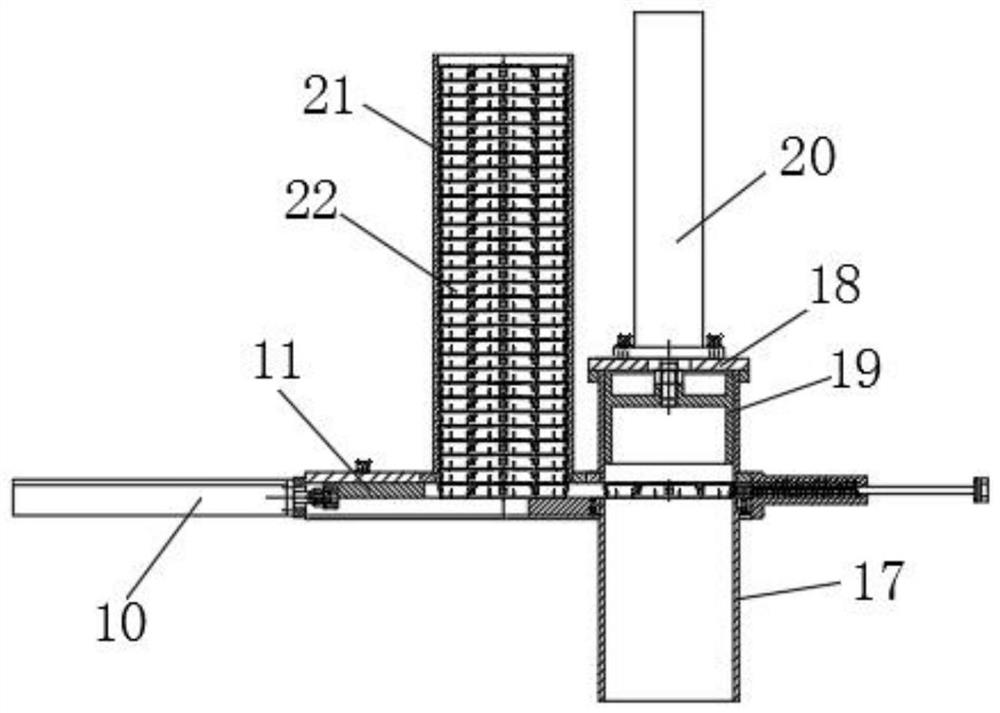

[0039] like Figure 1-4 As shown, a cold-dried instant soup is prepared by the following raw materials in parts by weight: 35 parts of millet, 15 parts of tremella, 25 parts of red beans, 8 parts of corn kernels, 10 parts of raisins, 5 parts of white sugar, 8 parts of soybean protein powder, 3 parts of papain, 50 parts of water;

[0040] A kind of production technology of cold-dried instant soup, the concrete steps of this technology are:

[0041] Step 1. Wash the white fungus, put the washed white fungus into the pot, add papain, and add water to the pot, heat the water to boiling, and set aside;

[0042] Step 2. Mix the millet, red beans, corn kernels and raisins, wash them, soak them in water for 5 hours, dry them, and fry them in a pot;

[0043] Step 3. Put the fried millet, red beans, corn kernels, raisins and soybean protein powder into white fungus, cook on low heat for 4 minutes, then add white sugar, continue to cook for 3 minutes, let cool, and get instant soup;

...

Embodiment 2

[0049] A cold-dried instant soup prepared from the following raw materials in parts by weight: 40 parts of millet, 20 parts of tremella, 30 parts of red beans, 10 parts of corn kernels, 15 parts of raisins, 8 parts of white sugar, soybean protein powder 12 parts, 5 parts of papain, 60 parts of water;

[0050] A kind of production technology of cold-dried instant soup, the concrete steps of this technology are:

[0051] Step 1. Wash the white fungus, put the washed white fungus into the pot, add papain, and add water to the pot, heat the water to boiling, and set aside;

[0052] Step 2. Mix the millet, red beans, corn kernels and raisins, wash them, soak them in water for 6 hours, dry them, and fry them in a pot;

[0053] Step 3. Put the fried millet, red beans, corn kernels, raisins and soybean protein powder into white fungus, cook on low heat for 7 minutes, then add white sugar, continue to cook for 5 minutes, let cool, and get instant soup;

[0054] Step 4, sending the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com