A kind of van der Waals dielectric material and its preparation method and application

A technology of dielectric materials and field effect transistors, applied in the field of two-dimensional material preparation, to achieve the effects of film thickness, good insulation properties, and good device properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

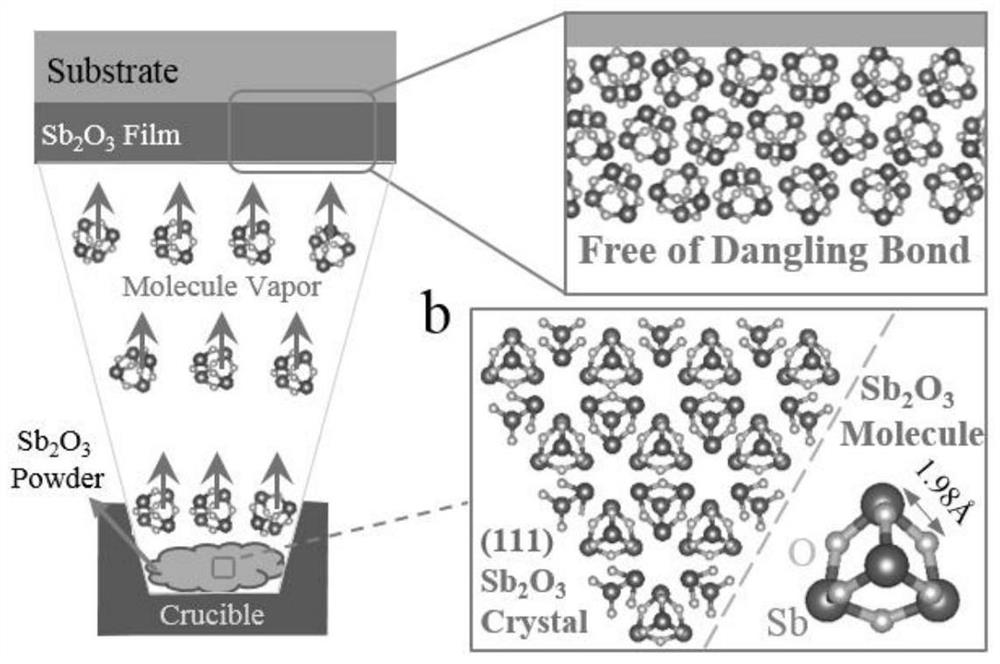

[0033] A method for preparing a van der Waals dielectric material provided by an embodiment of the present invention, such as figure 1 shown, including the following steps:

[0034] Inorganic molecular crystals are used as the evaporation source, and the method of thermal evaporation is adopted. Due to the weak van der Waals interaction between molecules, the evaporation source can be sublimated at a relatively low temperature under high vacuum conditions, so the internal structure of the molecule can be destroyed. In the case of high vacuum, the inorganic molecular crystals are sublimated to form molecular vapor, and then evaporated to obtain a van der Waals film. Since there are no unsaturated chemical bonds in the inorganic molecules, the surface of the prepared van der Waals film has no dangling bonds, and the van der Waals dielectric material is completed. preparation.

[0035] Further, the molecular crystal Sb with a band gap of 4eV 2 o 3 The powder is used as an evap...

Embodiment 1

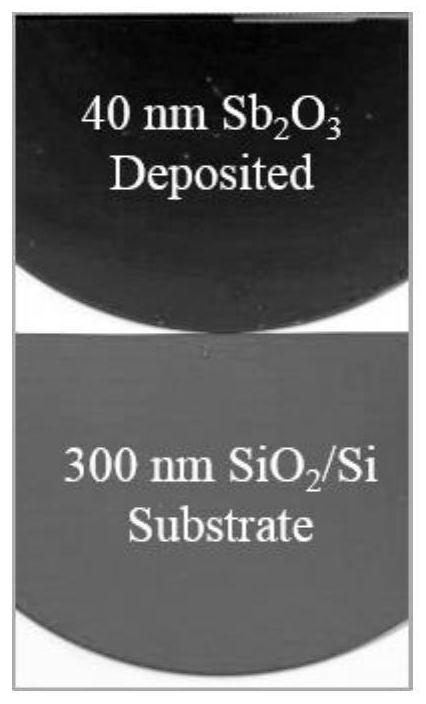

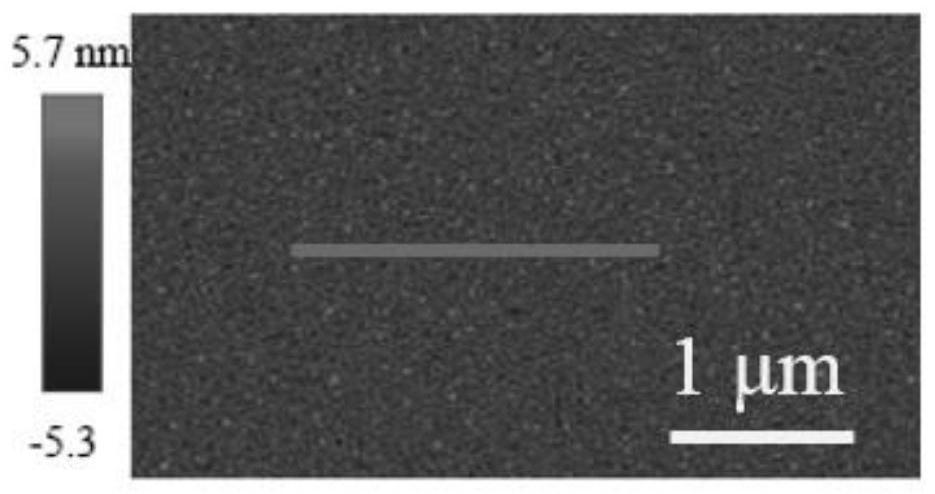

[0041] Choose inorganic molecular crystal Sb 2 o 3 As the evaporation source, silicon oxide is selected as the substrate, the molecular structure is maintained during the evaporation process, and the Sb evaporated on the substrate 2 o 3 There are no dangling bonds on the surface of the film, resulting in Sb 2 o 3 substrate. Such as figure 2 As shown, it is Sb with a thickness of 40nm prepared on a silicon oxide substrate 2 o 3 Thin film and substrate before evaporation, it can be seen that Sb on the entire substrate 2 o 3 The film has high uniformity; as Figure 3a and Figure 3b Shown, is the Sb under the atomic force microscope 2 o 3 The substrate and its surface relief curve, it can be seen that the Sb 2 o 3 The film is smooth and free of defects such as voids; Figure 4 Shown, for Sb 2 o 3 Raman optical characterization of the film, the results show that its Raman spectrum is consistent with that of the evaporated Sb 2 o 3 The Raman spectra of the powde...

Embodiment 2

[0043] Choose inorganic molecular crystal Sb 2 o 3 As the evaporation source, transparent glass is selected as the substrate, and the Sb evaporated on the substrate 2 o 3 No dangling bonds on film surface; test for Sb 2 o 3 The absorption spectrum of the thin film, such as Figure 5 As shown, by measuring the absorption spectrum, its forbidden band width is determined to be 4.0eV, indicating that Sb 2 o 3 Thin films are insulators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com