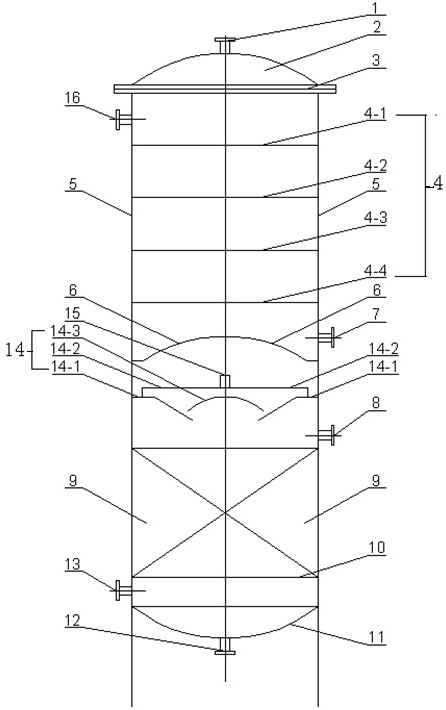

Graded pressure water oxygen dissolving device and implementation method

A technology of water dissolution and gas-liquid separation device, applied in the direction of dissolution, mixing methods, chemical instruments and methods, etc., can solve the problems of low oxygen utilization rate, low efficiency of dissolution equipment, energy consumption, etc., to improve utilization efficiency and reduce oxygen consumption Loss, easy maintenance and operation management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0018] River Oxygenation

[0019] The eutrophication of the river will cause the excessive consumption of dissolved oxygen in the water. The whole water body is severely hypoxic, anaerobic process occurs, and a large amount of odor and black sludge are produced, which seriously affects the ecosystem of the river. In order to improve the river system, black sludge should be eliminated. And the generation of odor, it is necessary to oxygenate the river water. Adopting the device of the invention can carry out effective oxygenation, is fast and efficient, and greatly reduces operating costs.

[0020] Use this graded oxygen dissolving device to dissolve oxygen into the water, and then release it into the river. Oxygen adopts industrial filling oxygen. 8kg / cm 2 The high-pressure capacity water flow rate is 2000kg / h, and the dissolved oxygen content is 402mg / L. After 48 hours of oxygenation in the river, the amount of oxygen used is 39.6kg. After comprehensive calculation, the ...

Embodiment example 2

[0022] Oxygenation for fish pond culture

[0023] It is necessary to maintain the dissolved oxygen content of the fish pond in the fish pond, and it is necessary to carry out oxygenation operation on the fish pond from time to time to maintain the dissolved oxygen content of the fish pond. Maintain the system balance of the whole fish pond. By adopting the device of the invention, the dissolved oxygen can be supplemented quickly according to the needs, and the cost of oxygenation can be greatly reduced.

[0024] Use this graded oxygen dissolving device to dissolve oxygen into the water, and then release it into the fish pond. Oxygen adopts industrial filling oxygen. 8kg / cm 2 The high-pressure capacity water flow rate is 1000kg / h, and the dissolved oxygen content is 398mg / L. After 2 hours of oxygenation, the amount of oxygen used is 0.82kg. After comprehensive calculation, the oxygen dissolution efficiency is 97.1%.

Embodiment example 3

[0026] Oxygenation in aerobic biological treatment in sewage treatment

[0027] In the process of aerobic biochemistry in sewage treatment, continuous oxygenation of sewage is required to ensure the normal growth and metabolism of microorganisms in sewage. In the metabolic process, dissolved oxygen, organic matter, trace elements, etc. are used as raw materials for microbial metabolism. Use this graded oxygen dissolving device to dissolve oxygen into water, and then release it into the aerobic biochemical pool. Oxygen adopts industrial filling oxygen. 8kg / cm 2 The high-pressure capacity water flow rate is 100kg / h, and the dissolved oxygen content is 392mg / L. After 48 hours of oxygenation, the amount of oxygen used is 1.95kg. After comprehensive calculation, the oxygen dissolution efficiency is 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com