Nitrogen-iron co-doped graphite carbon and preparation method and application thereof

A co-doping, graphitic carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as insufficient conductivity of catalysts, achieve favorable electron transfer, enrich oxygen reduction reaction active sites, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

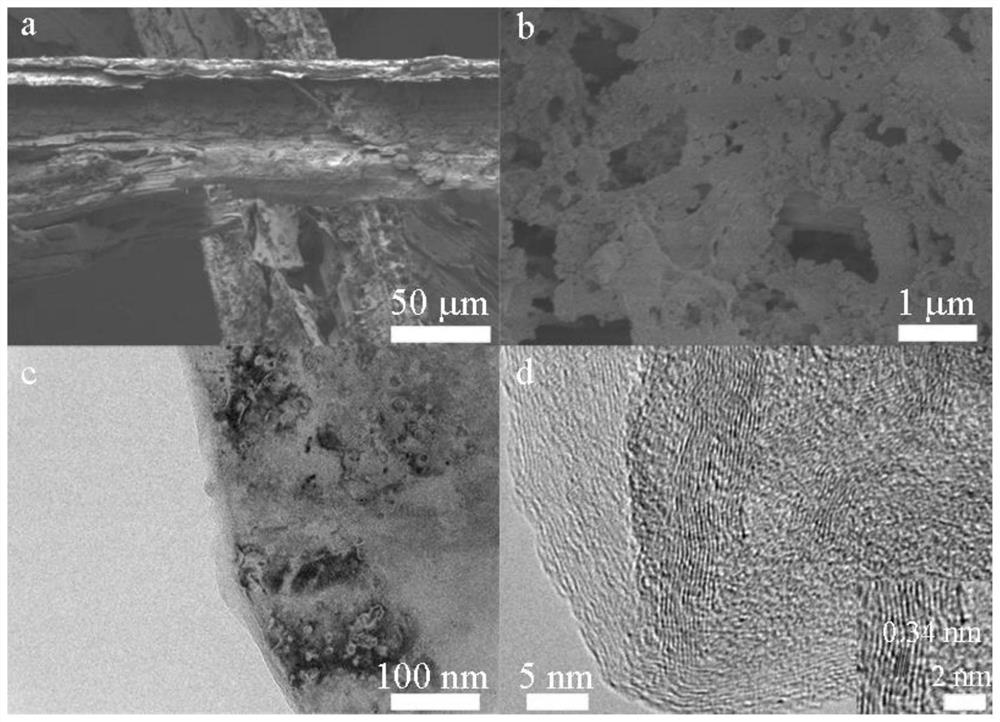

Image

Examples

Embodiment 1

[0049] The present embodiment provides a preparation method of nitrogen-iron co-doped graphite carbon, comprising the steps of:

[0050] S1: pretreating biomass raw material straw to obtain dry straw powder;

[0051] The pretreatment steps are as follows: wash the straw with clean water, cut it short after drying, and then put it into a ball mill for ball milling. The ball-to-material ratio is 10:1, the rotating speed is 200 rpm, and the ball milling time is 1 hour. After finishing the ball milling process, the obtained straw powder is washed, and blow-dried in a drying oven environment at 120° C. to obtain dry straw powder, and the length of the formed straw powder is 1 mm.

[0052] S2: Take 5g of potassium ferrate, 10g of straw powder and 40g of urea according to the ratio of potassium ferrate, urea and straw powder in a mass ratio of 0.5:4:1, add an appropriate amount of water to dissolve, stir well, and place in an oven Heat and dry at 50°C until the water in the mixture ...

Embodiment 2

[0065] The present embodiment provides a preparation method of nitrogen-iron co-doped graphite carbon, comprising the steps of:

[0066] S1: Pretreat fresh biomass raw material straw to obtain dry straw powder;

[0067] The pretreatment steps are as follows: wash the straw with clean water, cut it short after drying, and then put it into a ball mill for ball milling. The ball-to-material ratio is 10:1, the rotating speed is 200 rpm, and the ball milling time is 1 hour. After finishing the ball milling process, the obtained straw powder is washed, and blow-dried in a drying oven environment at 120° C. to obtain dry straw powder, and the length of the formed straw powder is 1 mm.

[0068] S2: Take 2g of potassium ferrate, 5g of straw powder and 15g of urea according to the ratio of potassium ferrate, urea and straw powder in a mass ratio of 0.4:3:1, add an appropriate amount of water to dissolve, stir well, and place in an oven Heat and dry at 40°C until the water in the mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com