Process for dip-coating fiber surface with emulsion polymerization chloroquine diphosphate microcapsules

A technology of chloroquine phosphate and emulsion polymerization, applied in the field of spinning, can solve the problems of fast release rate of antiviral agents and decreased antiviral effect, and achieve the effects of prolonging the effective time and enhancing the adhesion and cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

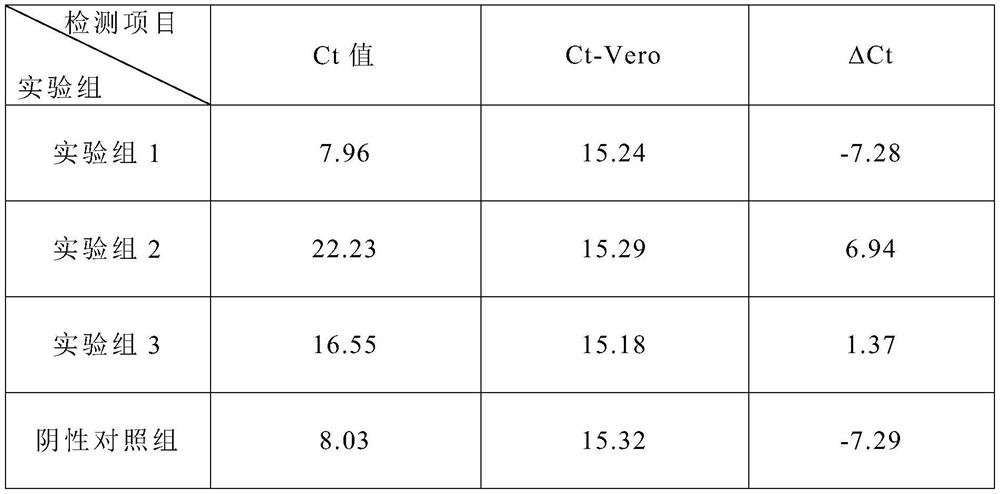

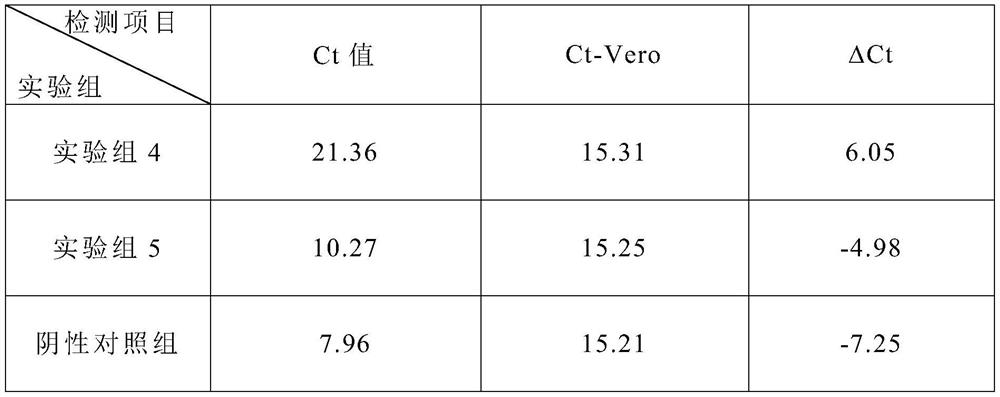

Embodiment 1

[0024] The present embodiment provides a kind of emulsion polymerization chloroquine phosphate microcapsule impregnation coating fiber surface technology, comprises the following steps:

[0025] Step 1: Send the acrylic fiber and hydroxypropyl methylcellulose into the horizontal mixer, and at the same time send the solvent DMAC through the elliptical flowmeter. There is a spiral propeller-type stirring blade in the horizontal mixer, and the distance between the blade and the wall is It is 10mm and the rotating speed is 60r / min. It is mixed by the rotation of the screw propeller and sent to the mixing tank. There is an agitator in the mixing tank. The agitator stirs to obtain the slurry, which is pumped to the dissolution tank and heated in the dissolution tank. Slurry until the slurry is dissolved into a uniform liquid to obtain a stock solution, and then add the stock solution to the spinning box;

[0026] Step 2: the stock solution in the spinning box is sprayed through the ...

Embodiment 2

[0036] The present embodiment provides a kind of emulsion polymerization chloroquine phosphate microcapsule impregnation coating fiber surface technology, comprises the following steps:

[0037] Step 1: Send the acrylic fiber and hydroxypropyl methylcellulose into the horizontal mixer, and at the same time send the solvent DMAC through the elliptical flowmeter. There is a spiral propeller-type stirring blade in the horizontal mixer, and the distance between the blade and the wall is 5mm, rotating speed is 90r / min, realize mixing by the rotation of the screw propeller and send to the mixing tank, the mixing tank is provided with an agitator, and the agitator stirs to obtain the slurry, which is pumped to the dissolving tank and heated in the dissolving tank Slurry until the slurry is dissolved into a uniform liquid to obtain a stock solution, and then add the stock solution to the spinning box;

[0038] Step 2: the stock solution in the spinning box is sprayed through the spinn...

Embodiment 3

[0044] The present embodiment provides a kind of emulsion polymerization chloroquine phosphate microcapsule impregnation coating fiber surface technology, comprises the following steps:

[0045] Step 1: Send the acrylic fiber and hydroxypropyl methylcellulose into the horizontal mixer, and at the same time send the solvent DMAC through the elliptical flowmeter. There is a spiral propeller-type stirring blade in the horizontal mixer, and the distance between the blade and the wall is 7mm, rotating speed is 75r / min, realize mixing by the rotation of the screw propeller and send to the mixing tank, the mixing tank is provided with an agitator, and the agitator stirs to obtain the slurry, which is pumped to the dissolving tank and heated in the dissolving tank Slurry until the slurry is dissolved into a uniform liquid to obtain a stock solution, and then add the stock solution to the spinning box;

[0046] Step 2: the stock solution in the spinning box is sprayed through the spinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com