High-protein dog snack and cat snack and preparation method thereof

A high-protein, snack technology, applied in the field of pet food, can solve the problems of increasing greenhouse gas methane emissions and increasing environmental burden, and achieve the effects of improving comprehensiveness, accelerating fecal excretion, and being easy to absorb and transform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

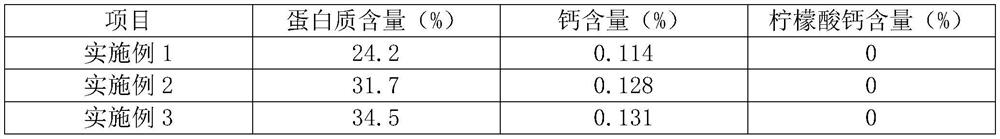

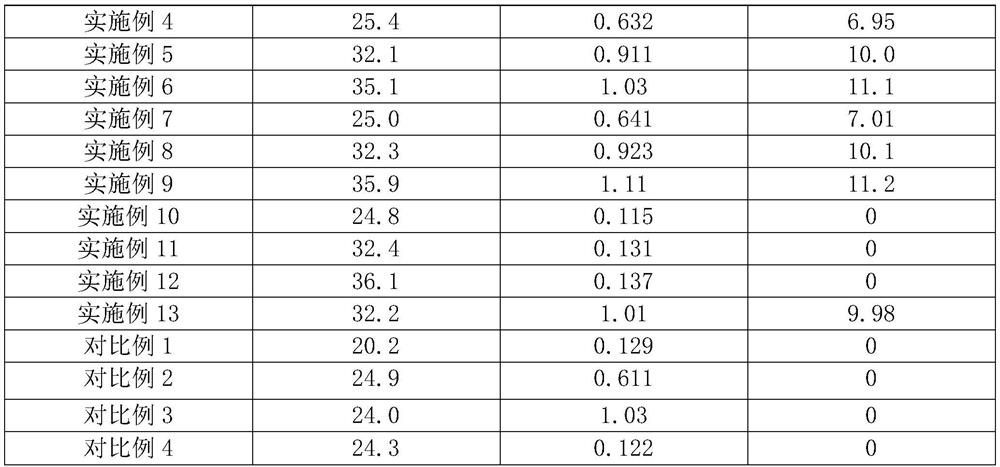

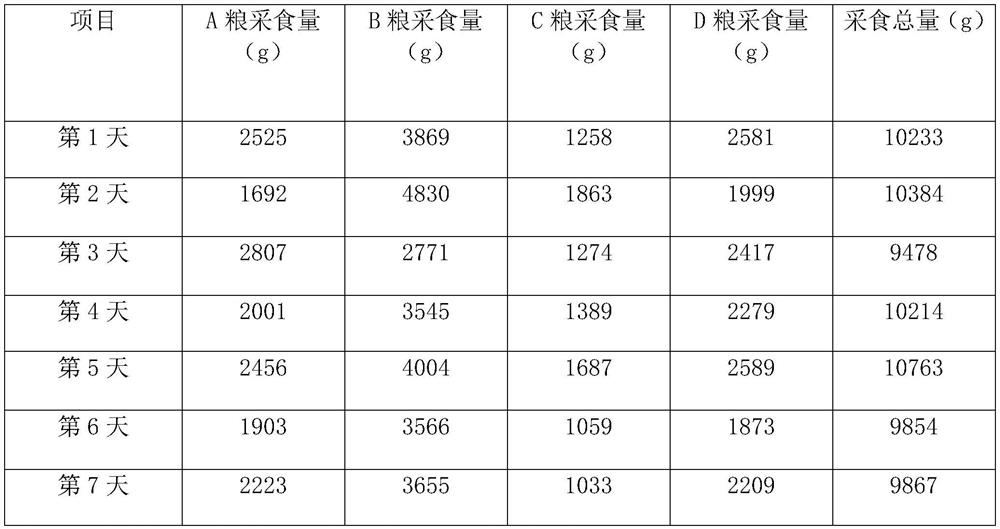

Examples

preparation example 1

[0039] (1) Enzymolysis: Weigh 15kg of cod bone meal, add it to 0.2kg flavored protease, add enough water, and then bathe in constant temperature water at pH 6.0 and temperature 50°C for 5 hours to obtain the enzymolysis mixture;

[0040] (2) Enzyme inactivation: heating the enzymolysis mixture obtained in (1) to 100° C. for enzymatic inactivation treatment;

[0041] (3) Filtration: Filtrating the enzymolysis mixture obtained in (2) to obtain the enzymolysis mixture supernatant and the enzymolysis mixture precipitate;

[0042] (4) Acidification: Weigh 1 kg of citric acid, add it to the precipitate of the enzymolysis mixture obtained in (3), and react the calcium citrate mixture obtained at pH 5.0 and a temperature of 30° C. for 5 hours;

[0043] (5) Mixing: adding the supernatant of the enzymolysis mixture obtained in (3) into the calcium citrate mixture obtained in (4), and mixing evenly to prepare a calcium preparation.

[0044] Animal bone meal includes, but is not limited ...

preparation example 2

[0046] (1) Enzymolysis: Weigh 20 kg of cod bone meal, add it to 0.3 kg of flavored protease, and obtain an enzymolysis mixture in a constant temperature water bath at pH 6.0 and temperature 50°C for 5 hours;

[0047] (2) Enzyme inactivation: heating the enzymolysis mixture obtained in (1) to 100° C. for enzymatic inactivation treatment;

[0048] (3) Filtration: Filtrating the enzymolysis mixture obtained in (2) to obtain the enzymolysis mixture supernatant and the enzymolysis mixture precipitate;

[0049] (4) Acidification: Weigh 1.5 kg of citric acid, add it to the enzymolysis mixture precipitate obtained in (3), and react the calcium citrate mixture obtained at pH 5.0 and temperature 30° C. for 5 h;

[0050] (5) Mixing: adding the supernatant of the enzymolysis mixture obtained in (3) into the calcium citrate mixture obtained in (4), and mixing evenly to prepare a calcium preparation.

[0051] Animal bone meal includes, but is not limited to, bovine bone meal, pork bone mea...

preparation example 3

[0053] (1) Enzymolysis: Weigh 25 kg of cod bone powder, add it to 0.4 kg of flavored protease, and obtain an enzymolysis mixture in a constant temperature water bath at pH 6.0 and temperature 50° C. for 5 hours;

[0054] (2) Enzyme inactivation: heating the enzymolysis mixture obtained in (1) to 100° C. for enzymatic inactivation treatment;

[0055] (3) Filtration: Filtrating the enzymolysis mixture obtained in (2) to obtain the enzymolysis mixture supernatant and the enzymolysis mixture precipitate;

[0056] (4) Acidification: Weigh 2 kg of citric acid, add it to the precipitate of the enzymolysis mixture obtained in (3), and react the calcium citrate mixture obtained at a pH of 5.0 and a temperature of 30° C. for 5 hours;

[0057] (5) Mixing: adding the supernatant of the enzymolysis mixture obtained in (3) into the calcium citrate mixture obtained in (4), and mixing evenly to prepare a calcium preparation.

[0058] Animal bone meal includes, but is not limited to, bovine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com