Phosphorus removal material as well as preparation method and application thereof

A technology of diatomite and lower layer, which is applied in the field of phosphorus removal materials and its preparation, can solve the problems of not meeting the needs of wastewater treatment, limited adsorption capacity of activated carbon, and increasing the cost of sewage treatment, etc., achieving low cost, good removal effect, and easy treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a method for preparing a phosphorus removal material, comprising the following steps:

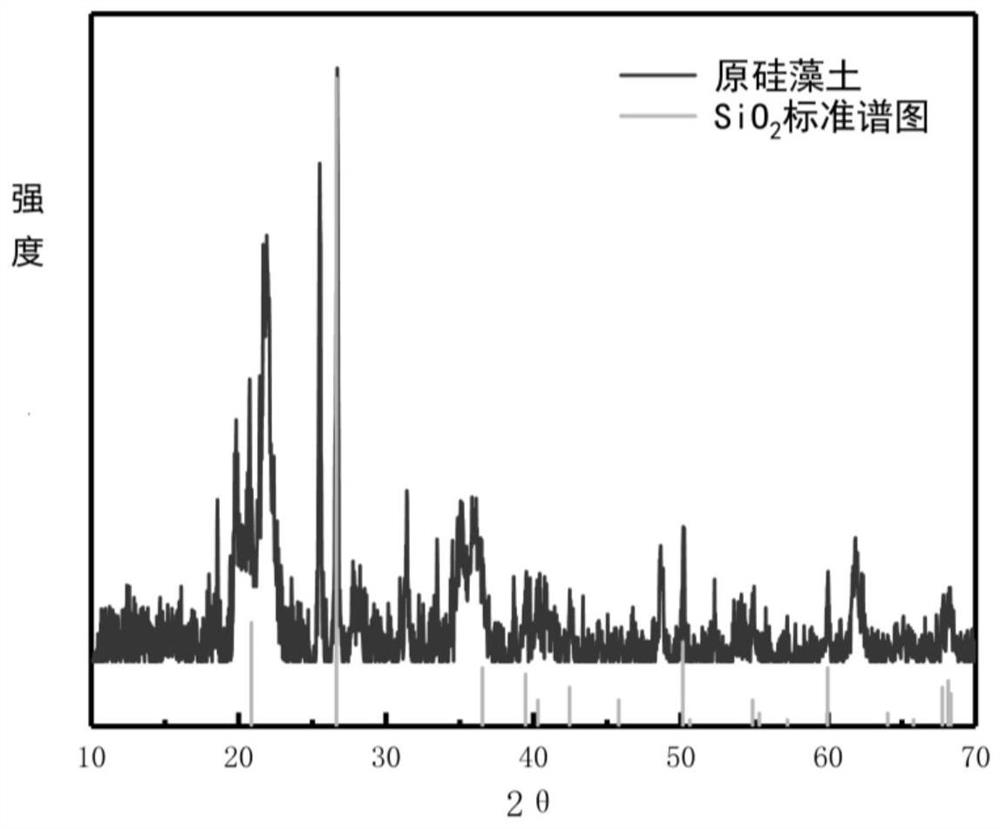

[0054] S1, the preparation of original diatomite:

[0055] Weigh 200g of diatomite, put it into a 500ml beaker, add dilute sulfuric acid with a volume concentration of 30%, until the diatomite is submerged, dilute sulfuric acid reacts with impurities in the diatomite to generate bubbles, and after no bubbles are produced, Add water to wash, leave to stand for stratification, pour out the upper layer of clear water, then add 400ml of sulfuric acid with a concentration of 30%, add water to wash, stand for stratification, repeat the operation 3 times, take off the layer, put it in a drying box, and dry it at 80 Dry at ℃ to constant weight, grind after drying, sieve with 200-mesh sieve, and calcinate at 400℃ for 2 hours to obtain the original diatomite.

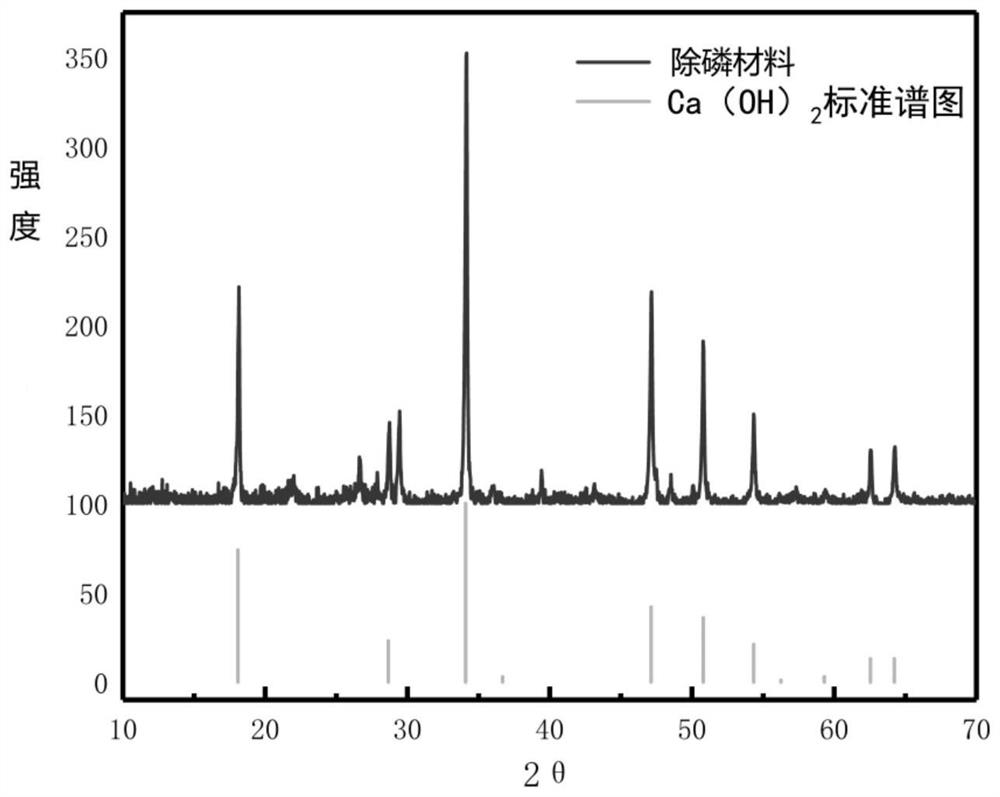

[0056] S2, preparation of phosphorus removal material:

[0057] Weigh 2.4g of glycine, 8g of calcium hydrox...

Embodiment 2

[0061] This embodiment provides a method for preparing a phosphorus removal material, comprising the following steps:

[0062] S1, the preparation of original diatomite:

[0063] Weigh 200g of diatomite, put it into a 500ml beaker, add dilute sulfuric acid with a volume concentration of 30%, until the diatomite is submerged, dilute sulfuric acid reacts with impurities in the diatomite to generate bubbles, and after no bubbles are produced, Add water to wash, leave to stand for stratification, pour out the upper layer of clear water, then add 400ml of sulfuric acid with a concentration of 30%, add water to wash, stand for stratification, repeat the operation 3 times, take off the layer, put it in a drying box, and dry it at 90 Dry at ℃ to constant weight, grind after drying, then sieve with 200-mesh sieve, and then calcined at 400℃ for 2 hours to obtain the original diatomite.

[0064] S2, preparation of phosphorus removal material:

[0065] Weigh 2.4g of glycine, 8g of calci...

Embodiment 3

[0069] This embodiment provides a method for preparing a phosphorus removal material, comprising the following steps:

[0070] S1, the preparation of original diatomite:

[0071] Weigh 200g of diatomite, put it into a 500ml beaker, add dilute sulfuric acid with a volume concentration of 30%, until the diatomite is submerged, dilute sulfuric acid reacts with impurities in the diatomite to generate bubbles, and after no bubbles are produced, Add water to wash, stand to separate layers, pour out the upper layer of clear water, then add 400ml of sulfuric acid with a concentration of 30%, add water to wash, stand to separate layers, repeat the operation 3 times, remove the layer, put it in a drying box, and dry it at 85 Dry at ℃ to constant weight, grind after drying, then sieve with 200-mesh sieve, and then calcined at 400℃ for 2 hours to obtain the original diatomite.

[0072] S2, preparation of phosphorus removal material:

[0073] Weigh 2.4g of glycine, 8g of calcium hydroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com