A kind of method that adopts microreactor to prepare alkyl aluminoxane

An alkylaluminoxane and microreactor technology, which is applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, compounds containing elements of Group 3/13 of the periodic table, etc. The effect of reaction temperature and reaction process is safe and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

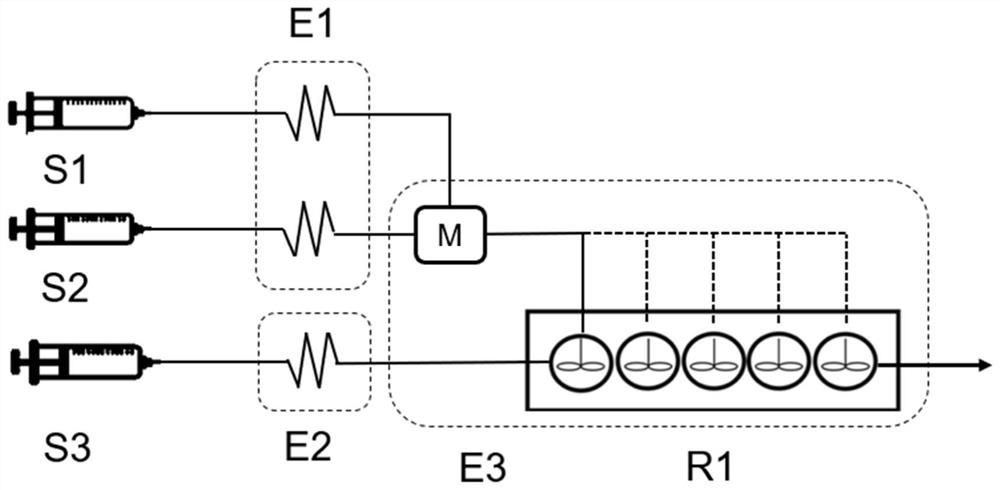

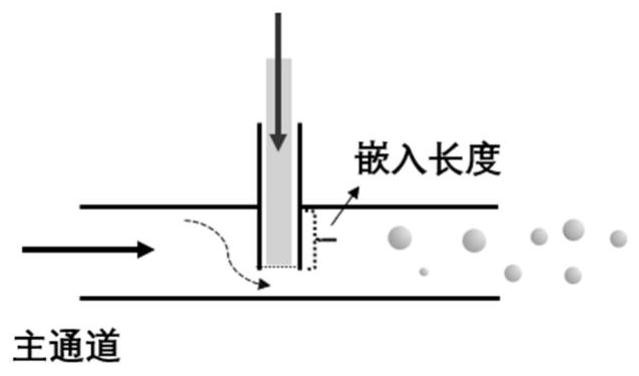

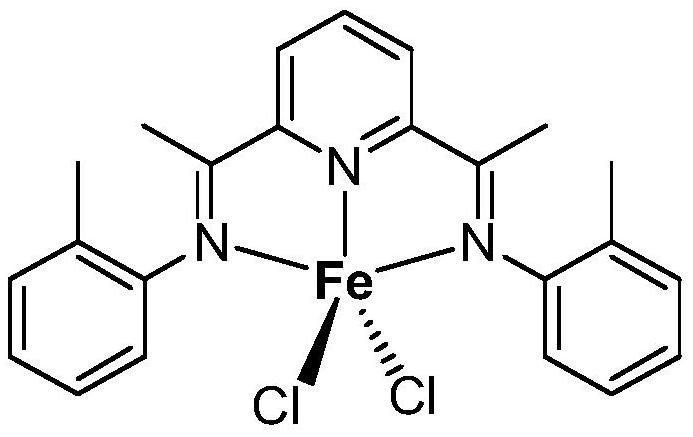

[0034] Before starting the reaction, the microreactor system was vacuum-dried and replaced with nitrogen. Syringe pumps S1 and S2 transport toluene and distilled water at a flow rate of 8mL / min and 60μL / min respectively. After passing through the heat exchange section E1, the temperature of the stream drops to 5°C and enters the liquid-liquid microdisperser to realize the microdispersion of water in toluene. The dispersed particle size of water droplets is 10-100μm. Syringe pump S3 delivers the toluene solution of trimethylaluminum at a flow rate of 8mL / min, with a mass fraction of 5%, and controls the temperature of the stream to 0°C after passing through heat exchange section E2. The microdisperser M and micro continuous stirring reactor R1 were placed in an ice-water bath to control the temperature at 0°C. The dispersed emulsion of water and toluene is fed from the top of reactor R1, and reacts with the toluene solution of trimethylaluminum in the second stirred tank. The ...

Embodiment 2

[0038] In order to improve production capacity, the concentration of trimethylaluminum toluene solution was increased to 10wt%. When starting the reaction, the trimethylaluminum toluene solution and toluene stream were still delivered at 8mL / min, and distilled water was injected at 120μL / min. The molar ratio of aluminum was 0.7. Other reaction process, condition, device parameter are all the same as embodiment 1. The yield of methylaluminoxane at the end of the reaction was 69%.

Embodiment 3

[0040] 5wt% trimethylaluminum toluene solution was delivered to the reaction system at a flow rate of 8mL / min, distilled water was injected at 69μL / min, and dispersed with toluene stream, the flow rate was 8mL / min, and the molar ratio of water to trimethylaluminum was controlled as 0.8. Other reaction process, condition, device parameter are all the same as embodiment 1. At the end of the reaction, the yield of methylaluminoxane was 70.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com