A method for preparing covalent organic framework materials by mechanical ball milling

A technology of covalent organic framework and ball milling, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve the problems of large amount of organic solvent usage, long synthesis time, etc., and achieve short reaction time , low cost of reaction conditions, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

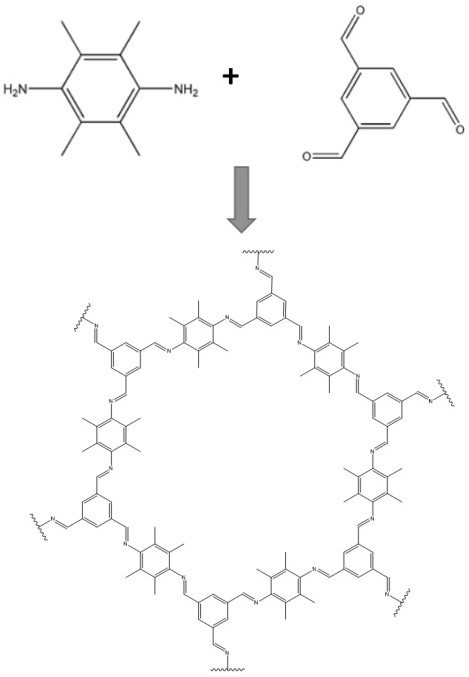

[0025] S1. Under the protection of nitrogen gas, evenly mix 2,3,5,6-tetramethyl-p-phenylenediamine and trimesin triformaldehyde in a molar ratio of 1:1 and put them into a stainless steel ball mill tank, then add p-toluenesulfonic acid ball mill Liquid 1mL;

[0026] S2. Put the ball mill jar into a planetary ball mill at a room temperature of 0°C. After adding stainless steel medium balls into the ball mill according to the ball-to-material ratio of 10:1, the ball milled at a speed of 100r / min for 100min;

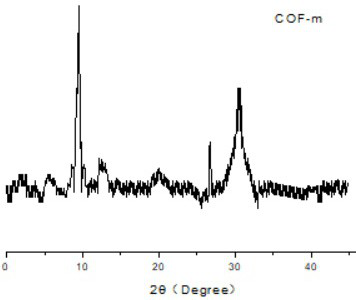

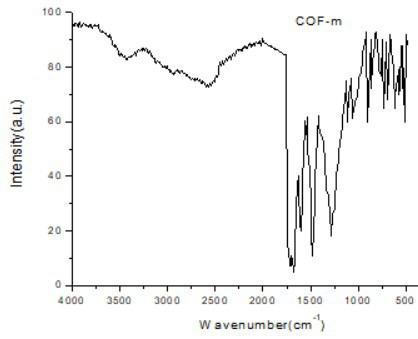

[0027] S3. After the reaction is over, the product is removed under a nitrogen atmosphere, the product is washed with trimethylbenzene, ultrapure water and acetone in sequence, dried at 90°C for 12h, and then heated to 120°C for 3h to obtain a total Valence organic framework materials COF-m. The specific synthesis steps are shown in 1.

[0028] Application of covalent organic framework material COF-m in the adsorption of pollutants in water: In a 250mL Erlenmeyer flask, ...

Embodiment 2

[0034] S1. Under the protection of nitrogen atmosphere, uniformly mix 2,3,5,6-tetramethyl-p-phenylenediamine and trimesaldehyde in a molar ratio of 1:1 and put them into a stainless steel ball mill tank, then add p-toluenesulfonic acid ball mill Liquid 1mL;

[0035] S2. Put the ball mill jar into the planetary ball mill at a room temperature of 20°C. After adding stainless steel medium balls into the ball mill according to the ball-to-material ratio of 10:1, the ball mill reacted at a speed of 100r / min for 200min;

[0036] S3. After the reaction is over, the product is removed under a nitrogen atmosphere, the product is washed with trimethylbenzene, ultrapure water and acetone in sequence, dried at 90°C for 12h, and then heated to 120°C for 3h to obtain a total Valence organic framework materials COF-m.

[0037] Application of covalent organic framework material COF-m in the adsorption of pollutants in water: In a 250mL Erlenmeyer flask, add 100mg of COF-m material to 100mL ...

Embodiment 3

[0041] S1. Under the protection of nitrogen atmosphere, uniformly mix 2,3,5,6-tetramethyl-p-phenylenediamine and trimesaldehyde raw materials at a molar ratio of 2:3 and add them to a stainless steel ball mill tank, then add p-toluenesulfonic acid ball mill Liquid 3mL;

[0042] S2. Put the ball mill jar into the planetary ball mill at a room temperature of 20°C. After adding stainless steel medium balls into the ball mill according to the ball-to-material ratio of 10:1, the ball mill reacted at a speed of 300r / min for 200min;

[0043] S3. After the reaction is over, the product is removed under a nitrogen atmosphere, the product is washed with trimethylbenzene, ultrapure water and acetone in sequence, dried at 90°C for 12h, and then heated to 120°C for 3h to obtain a total Valence organic framework materials COF-m.

[0044] Application of covalent organic framework material COF-m in the adsorption of pollutants in water: In a 250mL Erlenmeyer flask, add 100mg of COF-m materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com