Biodegradable composite cable and preparation method thereof

A composite cable and biodegradation technology, which is applied in the field of composite materials, can solve the problems of little research on the environmental protection performance of wires or cables, the degradation effect is not obvious, the toughness and strength decrease, etc., to achieve outstanding nucleation performance, shorten the biodegradation cycle, Effect of improving strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

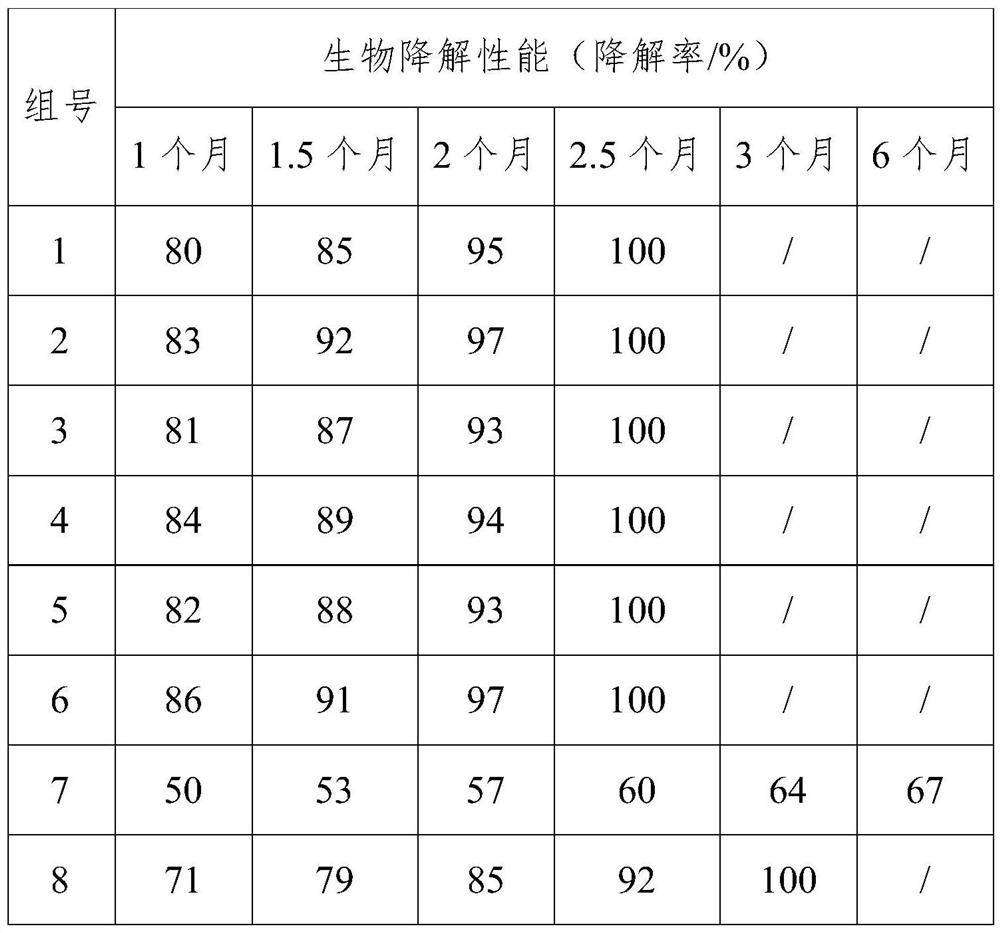

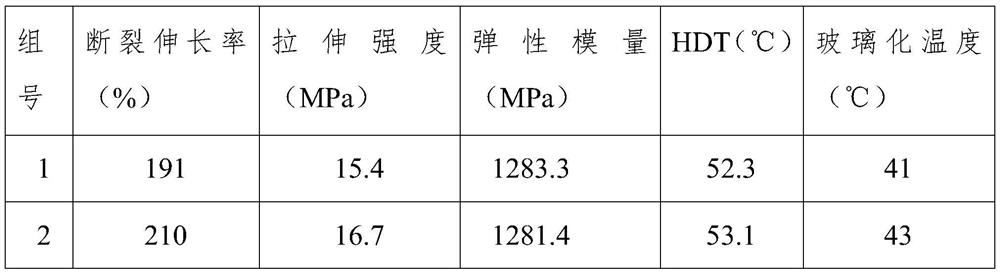

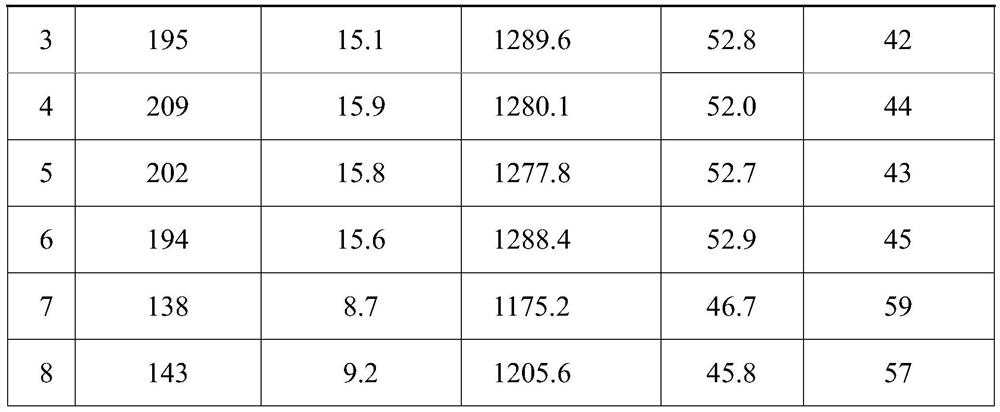

Examples

preparation example Construction

[0030] A method for preparing a biodegradable composite cable, comprising the following steps:

[0031] (1) Place polylactic acid, hemp fiber, nanocellulose, soft toughening agent and hard toughening agent in a drying oven for drying, wherein polylactic acid, nanocellulose and hemp fiber are separated at 50-60 Dry for 15-20 hours at ℃, dry for 15-20 hours for soft toughener at 40-50℃, and dry for 2-5 hours for hard toughener at 90-100℃;

[0032] (2) add the twin-screw extruder after the soft toughening agent after drying, hard toughening agent and coupling agent, crosslinking agent melt and mix, the material after extruding is cooled, obtains material A; Material A After mixing with polylactic acid and hemp fiber, add it to a twin-screw extruder and extrude it into a molten state;

[0033] (3) Rapidly pour the prepared molten body into a mold to cool and shape it, and after drying, trim the edges with a pelletizer to obtain the cable material.

[0034] In this embodiment, in...

Embodiment 1

[0039] A biodegradable composite cable, comprising the following components in parts by weight: 50 parts of polylactic acid, 15 parts of hemp fiber, 10 parts of microfibrillated cellulose, ethylene-methyl acrylate-glycidyl methacrylate 1 part of copolymer, 1 part of talcum powder, 1 part of silane coupling agent, 1 part of borax.

[0040] A method for preparing a biodegradable composite cable, comprising the following steps:

[0041] (1) Put polylactic acid, hemp fiber, microfibrillated cellulose, soft toughening agent and hard toughening agent in a drying oven for drying, wherein polylactic acid, microfibrillated cellulose and hemp Dry the hemp fiber at 50°C for 15 hours, dry the soft toughening agent at 40°C for 15 hours, and dry the hard toughening agent at 90°C for 2 hours;

[0042] (2) add the twin-screw extruder after the soft toughening agent after drying, hard toughening agent and coupling agent, crosslinking agent melt and mix, the material after extruding is cooled, o...

Embodiment 2

[0045] A biodegradable composite cable, comprising the following components in parts by weight: 70 parts of polylactic acid, 25 parts of hemp fiber, 20 parts of microfibrillated cellulose, ethylene-methyl acrylate-glycidyl methacrylate 5 parts of copolymer, 5 parts of talcum powder, 5 parts of silane coupling agent, 5 parts of borax.

[0046] A method for preparing a biodegradable composite cable, comprising the following steps:

[0047] (1) Put polylactic acid, hemp fiber, microfibrillated cellulose, soft toughening agent and hard toughening agent in a drying oven for drying, wherein polylactic acid, microfibrillated cellulose and hemp Dry the hemp fiber at 60°C for 20 hours, dry the soft toughener at 50°C for 20 hours, and dry the hard toughener at 100°C for 5 hours;

[0048] (2) add the twin-screw extruder after the soft toughening agent after drying, hard toughening agent and coupling agent, crosslinking agent melt and mix, the material after extruding is cooled, obtains ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com