A kind of preparation method of neutral protease

A technology of neutral protease and fermentation medium, applied in the direction of microorganism-based methods, biochemical equipment and methods, hydrolytic enzymes, etc., can solve the problems of low enzyme activity, improve enzyme activity, promote fermentation enzyme production, and solve enzyme The effect of low vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

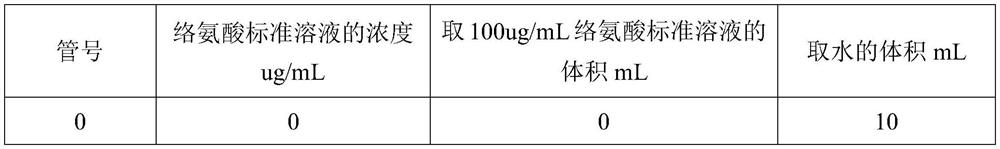

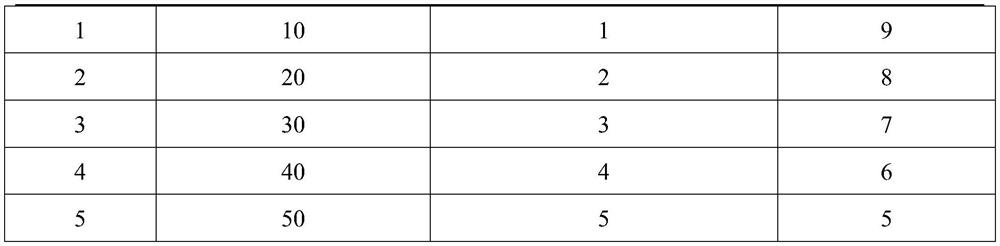

Image

Examples

Embodiment 1

[0032] A preparation method for neutral protease, comprising the following steps:

[0033] A, Bacillus subtilis seed liquid is inoculated into fermentation medium according to 5% inoculation amount and carries out fermentation culture, and fermentation medium comprises the component of following parts by weight: 40 parts of sweet potato starches, 25 parts of bean cake powders, 7 powders of pumpkin powders, 1.3 parts of magnesium humate, 1 part of calcium complexate, 0.7 parts of dipotassium hydrogen phosphate, 1.2 parts of ammonium chloride, 1.1 parts of sodium nitrate, 450 parts of water, the pH value of the fermentation medium is 6.6; the culture temperature is 27°C , the culture time is 14h, obtains initial fermented liquid;

[0034] B. Add feed medium feed to the primary fermentation liquid, feed medium includes the following components by weight: 1 part of methanol, 10 parts of carrot powder, 8 parts of shrimp shell powder, 14 parts of glucose, 1.2 parts of diglyceride p...

Embodiment 2

[0040] A preparation method for neutral protease, comprising the following steps:

[0041] A, Bacillus subtilis seed liquid is inoculated into fermentation medium according to 6% inoculation amount and carries out fermentation culture, and fermentation medium comprises the component of following weight portion: 40 parts of sweet potato starches, 25 parts of bean cake powders, 7 powders of pumpkin powders, 1.3 parts of magnesium humate, 1 part of calcium complexate, 0.7 parts of dipotassium hydrogen phosphate, 1.2 parts of ammonium chloride, 1.1 parts of sodium nitrate, 450 parts of water, the pH value of the fermentation medium is 6.6; the culture temperature is 27°C , the culture time is 15h, obtains initial fermented liquor;

[0042] B. Add feed medium feed to the primary fermentation liquid, feed medium includes the following components by weight: 1 part of methanol, 10 parts of carrot powder, 8 parts of shrimp shell powder, 14 parts of glucose, 1.2 parts of diglyceride pa...

Embodiment 3

[0048] A preparation method for neutral protease, comprising the following steps:

[0049] A, Bacillus subtilis seed liquid is inoculated into fermentation medium according to 8% inoculation amount and carries out fermentation culture, and fermentation medium comprises the component of following parts by weight: 40 parts of sweet potato starches, 25 parts of bean cake powders, 7 powders of pumpkin powders, 1.3 parts of magnesium humate, 1 part of calcium complexate, 0.7 parts of dipotassium hydrogen phosphate, 1.2 parts of ammonium chloride, 1.1 parts of sodium nitrate, 450 parts of water, the pH value of the fermentation medium is 6.6; the culture temperature is 27°C , the culture time is 16h, obtains initial fermented liquid;

[0050] B. Add feed medium feed to the primary fermentation liquid, feed medium includes the following components by weight: 1 part of methanol, 10 parts of carrot powder, 8 parts of shrimp shell powder, 14 parts of glucose, 1.2 parts of diglyceride p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com