Three-layer composite functionalized CPP film for power lithium battery soft coating film and preparation method thereof

A functional and layer-combined technology, applied in the field of composite membranes, can solve the problems of CPP’s electrolyte resistance, aluminum foil delamination and shedding, which are difficult to balance, and achieve the effect of solving the delamination and shedding problem and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

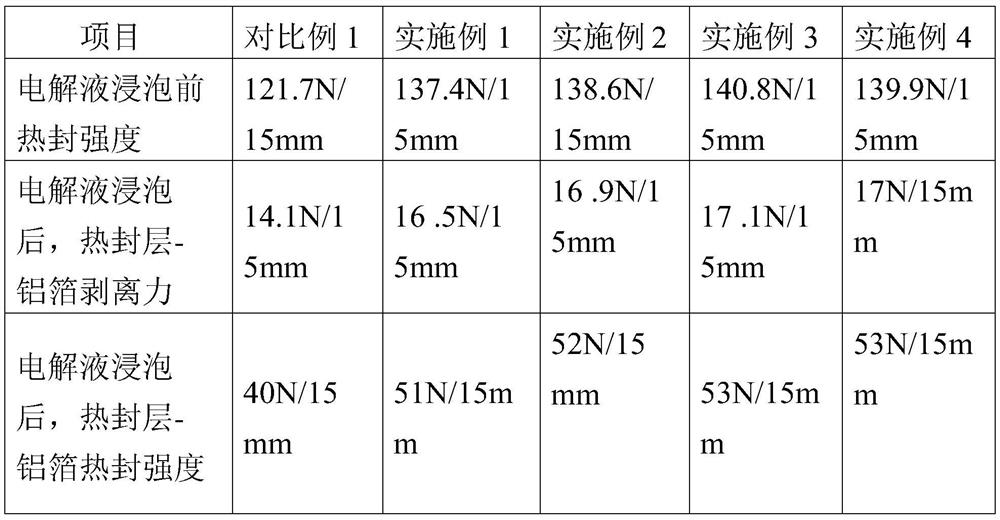

Examples

preparation example Construction

[0029] Two, a kind of preparation method of the three-layer composite functionalized CPP film that is used for power lithium battery soft coating, comprises steps:

[0030] (1) Graft modified polypropylene particles are added to the first hopper of the extruder, and then enter the first passage of the die head;

[0031] (2) Put polypropylene granules into the first mixing tank, add nanomaterials into the first mixing tank, and fully stir under the conditions of the rotation speed of 100r / min to 300r / min and the temperature of 20°C to 35°C to obtain The middle layer material, the middle layer material is added to the second hopper of the extruder, and then enters the second channel of the die head;

[0032] (3) Put the polypropylene particles into the second mixing tank, add the nucleating agent into the second mixing tank, and stir thoroughly under the conditions of the rotating speed of 100r / min~300r / min and the temperature of 20℃~35℃ Obtain the inner layer material, add the...

Embodiment 1

[0049] (1) Maleic anhydride grafted modified polypropylene particles are added in the first hopper of the extruder, and then enter the first passage of the die head;

[0050] (2) Polypropylene particles are put into the first mixing tank, and nano-flaky zinc oxide is added in the first mixing tank, the mass ratio of nano-flaky zinc oxide to polypropylene particles is 0.1%, and the rotating speed is 100r / minr / min, the temperature is 20 ° C under the condition of sufficient stirring to obtain the middle layer material, the middle layer material is added to the second hopper of the extruder, and then enters the second channel of the die head;

[0051] (3) Put the polypropylene particles into the second mixing tank, add a nucleating agent to the second mixing tank, the nucleating agent is a rosin-type nucleating agent, under the conditions of a rotating speed of 100r / min and a temperature of 20°C After fully stirring to obtain the inner layer material, add the inner layer materia...

Embodiment 2

[0060] (1) Maleic anhydride grafted modified polypropylene particles are added in the first hopper of the extruder, and then enter the first passage of the die head;

[0061] (2) Polypropylene particles are put into the first mixing tank, and nano-flaky zinc oxide is added in the first mixing tank, the mass ratio of nano-flaky zinc oxide to polypropylene particles is 1.5%, and the rotating speed is 200r / min , the temperature is 28 ° C under the condition of sufficient stirring to obtain the middle layer material, the middle layer material is added to the second hopper of the extruder, and then enters the second channel of the die head;

[0062] (3) Put the polypropylene granules into the second mixing tank, add a nucleating agent to the second mixing tank, the nucleating agent is a polymer nucleating agent, under the condition that the rotating speed is 200r / min and the temperature is 28°C After fully stirring to obtain the inner layer material, add the inner layer material to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com