SBS modified asphalt concrete and preparation method thereof

A technology for modifying asphalt and concrete, applied in the field of pavement paving materials, can solve the problems of caking, reducing the partial performance of modified asphalt concrete, and being difficult to dissolve and disperse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

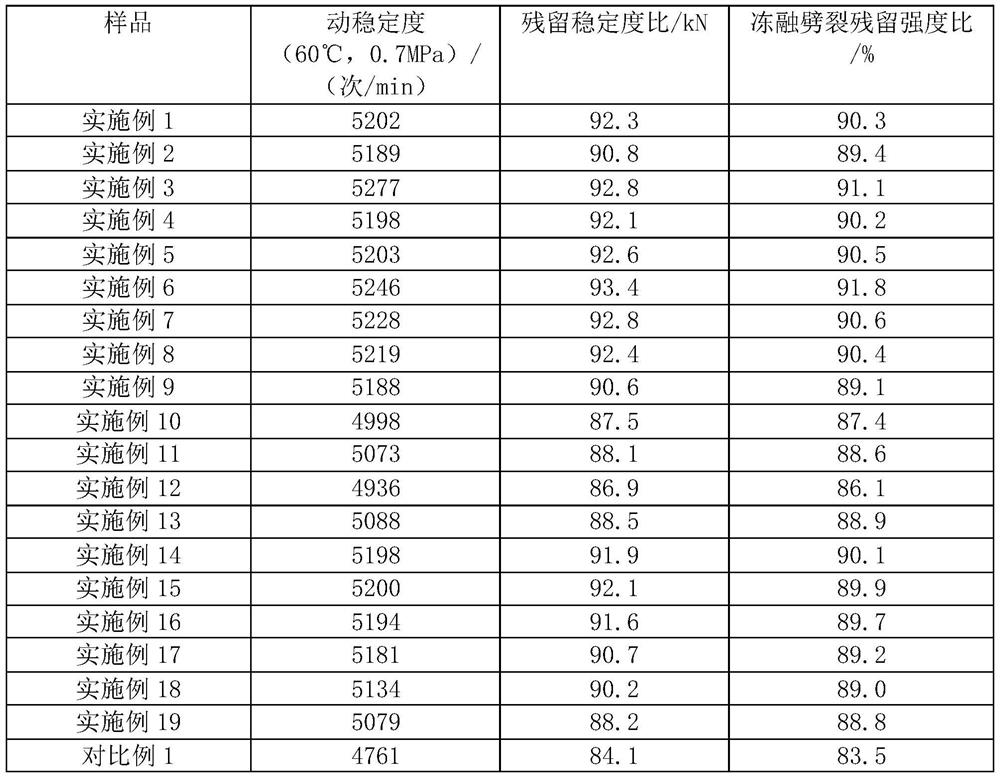

Examples

Embodiment 1

[0031] Embodiment 1 is a kind of SBS modified asphalt concrete disclosed by the present invention and its preparation method,

[0032] SBS modified asphalt concrete includes the following components by weight: 400 parts of gravel, slag and natural sand with a mass ratio of 1:0.4:0.6, 22.5 parts of asphalt, 7.5 parts of chopped glass fiber modified polypropylene fiber, and 2.5 parts of SBS And a particle diameter of 150 mesh crosslinking agent particles;

[0033] The crosslinking agent particles include the following components in parts by weight: 75 parts of liquid coumarone resin, 20 parts of sulfur, 7.5 parts of chloroform and 1.5 parts of tin methyl mercaptide;

[0034]The preparation method of the crosslinking agent particles is as follows: 1) adding 0.7% ethanol of its total weight to chloroform, stirring evenly to obtain a solvent; 2) adding sulfur into a high-speed disperser to disperse evenly, and then adding Step 1) in the solvent, sulfur is dissolved in the solvent ...

Embodiment 2

[0041] Embodiment 2 is a kind of SBS modified asphalt concrete disclosed by the present invention and its preparation method,

[0042] SBS modified asphalt concrete includes the following components by weight: 300 parts of gravel, slag and natural sand with a mass ratio of 1:0.4:0.6, 15 parts of asphalt, 5 parts of chopped glass fiber modified polypropylene fiber, and 1.5 parts of SBS And the particle diameter is 0.5 parts of crosslinking agent particles of 100 mesh;

[0043] The crosslinking agent particles include the following components in parts by weight: 75 parts of liquid coumarone resin, 20 parts of sulfur, 7.5 parts of chloroform and 1.5 parts of tin methyl mercaptide;

[0044] The preparation method of the crosslinking agent particles is as follows: 1) adding 0.6% ethanol of its total weight to chloroform, stirring evenly to obtain a solvent; 2) adding sulfur into a high-speed disperser to disperse evenly, and then adding Step 1) in the solvent, sulfur is dissolved ...

Embodiment 3

[0046] Embodiment 3 is a kind of SBS modified asphalt concrete disclosed by the present invention and its preparation method,

[0047] SBS modified asphalt concrete includes the following components by weight: 500 parts of gravel, slag and natural sand with a mass ratio of 1:0.4:0.6, 30 parts of asphalt, 10 parts of chopped glass fiber modified polypropylene fiber, and 3.5 parts of SBS And particle diameter is 1.5 parts of crosslinking agent particles of 200 mesh;

[0048] The crosslinking agent particles include the following components in parts by weight: 75 parts of liquid coumarone resin, 20 parts of sulfur, 7.5 parts of chloroform and 1.5 parts of tin methyl mercaptide;

[0049] The preparation method of the crosslinking agent particles is as follows: 1) adding 0.8% ethanol of its total weight to chloroform, stirring evenly to obtain a solvent; 2) adding sulfur into a high-speed disperser to disperse evenly, and then adding Step 1) in the solvent, sulfur is dissolved in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com