Crude tin smelting system and process

A crude tin and process technology, which is applied in the crude tin smelting system and process field, can solve the problems of unfavorable smelting efficiency and environmental protection, large material dispersion and turnover, complex and lengthy process, etc., and achieve reduction of fugitive emissions and dust, small investment and high process efficiency. short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

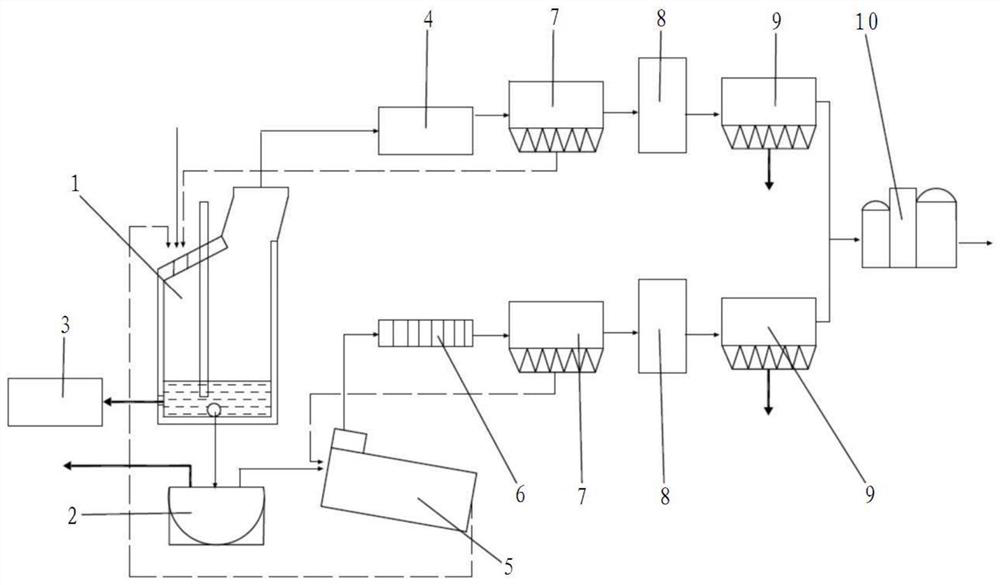

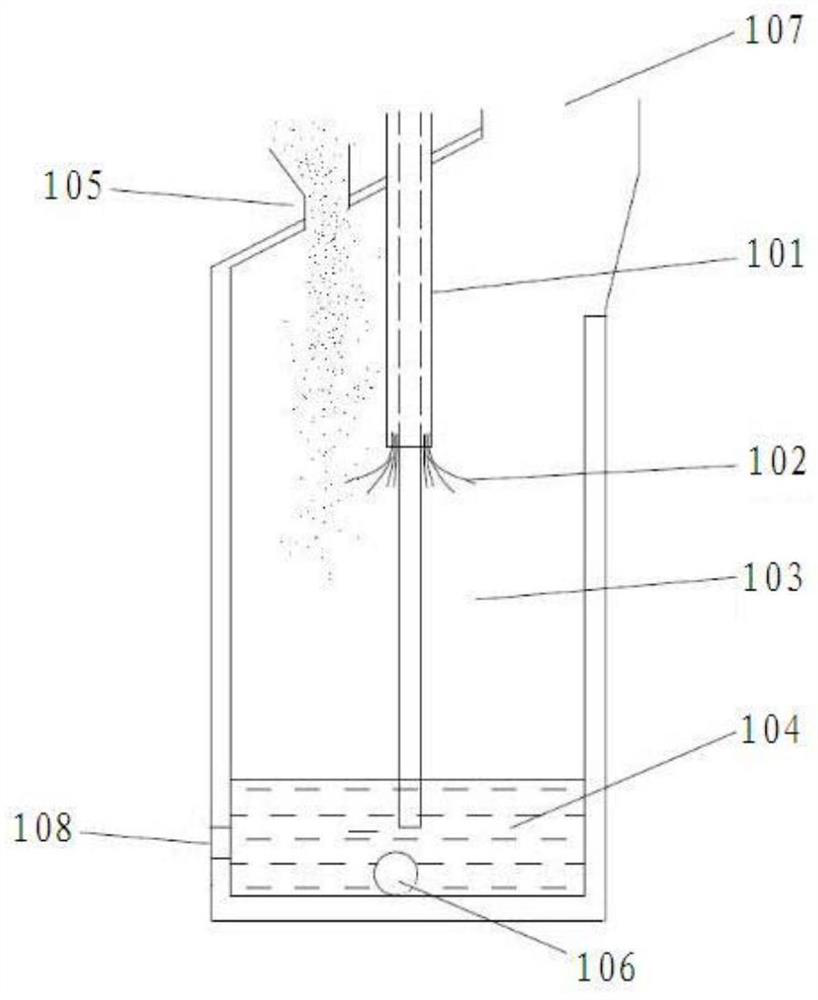

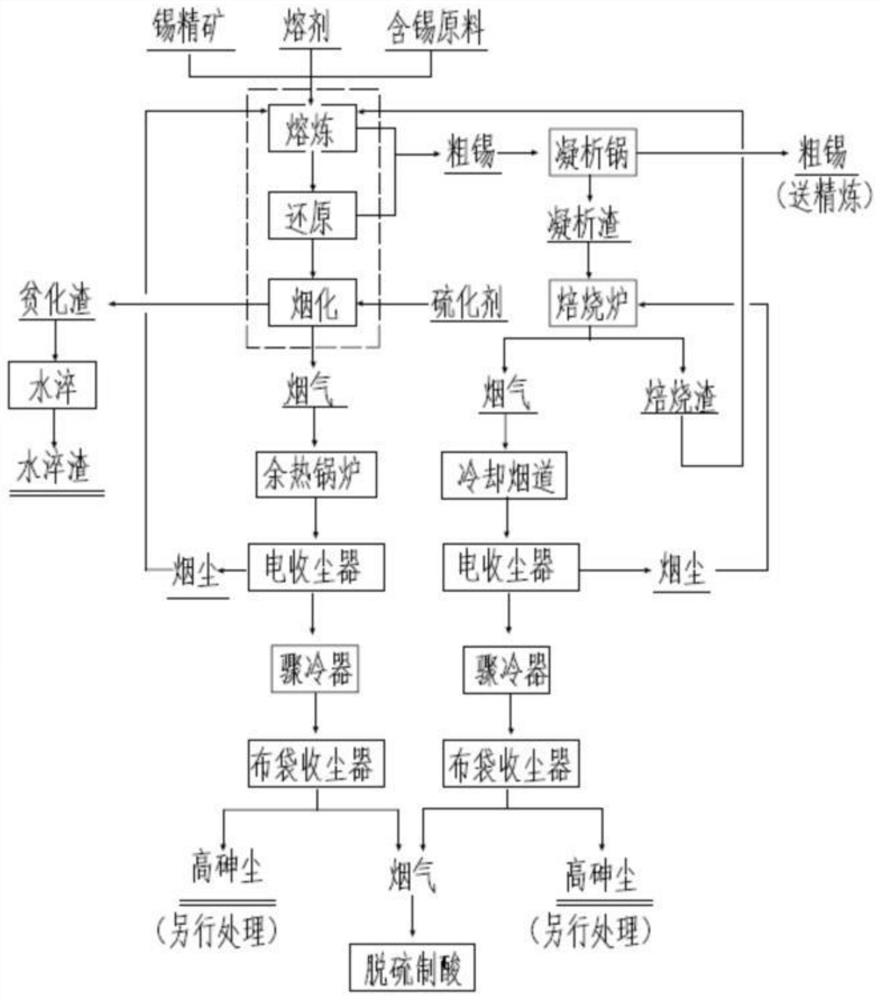

[0036] 1) Continuously add tin concentrate, tin-containing raw materials and flux into the top-blown furnace 1 for smelting, reduction and slag fuming; the air in the smelting stage is oxygen-enriched air containing 30-35% oxygen; In the stage, according to the sulfur content (1.5%) of the concentrate, secondary air is blown into the upper part of the furnace of the top-blowing furnace to completely burn the volatile matter; when the tin content in the slag is reduced to 3.5%, all the crude tin in the top-blowing furnace 1 is discharged To the condensate pot 2, the slag is not discharged;

[0037] 2) Continue to add 6-8cm agglomerates or bricks of the same volume to the top-blowing furnace 1 (to reduce the sulfur loss during the process of falling from the top-blowing furnace to the molten pool) for slag fuming, when the slag contains When the tin content is 0.16%, the fuming is finished, and the tin-poor slag is discharged from the slag outlet of the top blowing furnace 1 to ...

Embodiment 2

[0043] 1) Continuously add tin concentrate, tin-containing raw materials and flux into the top-blown furnace 1 for smelting, reduction and slag fuming; the air in the smelting stage is oxygen-enriched air containing 39-42% oxygen; In the first stage, according to the sulfur content (3%) in the concentrate, secondary air is blown into the upper part of the furnace of the top-blowing furnace to completely burn the volatile matter; when the tin content in the slag is reduced to 3%, all the crude tin in the top-blowing furnace 1 is discharged To the condensate pot 2, the slag is not discharged;

[0044] 2) Continue to add 7-9cm agglomerates or bricks of the same volume to the top-blowing furnace 1 (to reduce the sulfur loss during the process of falling from the top-blowing furnace to the molten pool) for slag fuming, when the slag contains When the tin content is 0.15%, the fuming is finished, and the tin-poor slag is discharged from the slag outlet of the top blowing furnace 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com