A modified polypropylene insulated multi-core cable with high ampacity

A multi-core cable and polypropylene technology, applied in the direction of insulated cables, insulators, insulated conductors, etc., can solve problems such as safety hazards, limited performance, and environmental pollution, and achieve the effects of improving quality, high structural stability, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

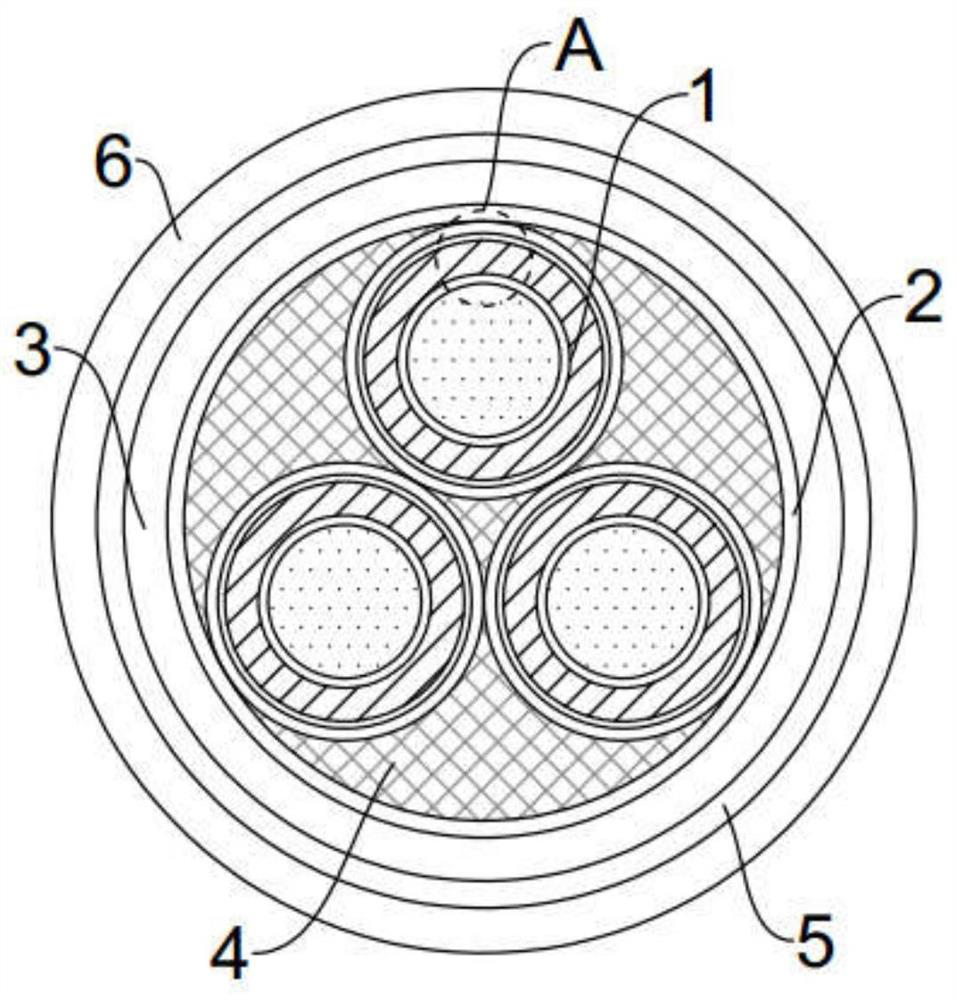

[0058] a kind of like figure 1 Shown is a high ampacity modified polypropylene insulated multi-core cable comprising:

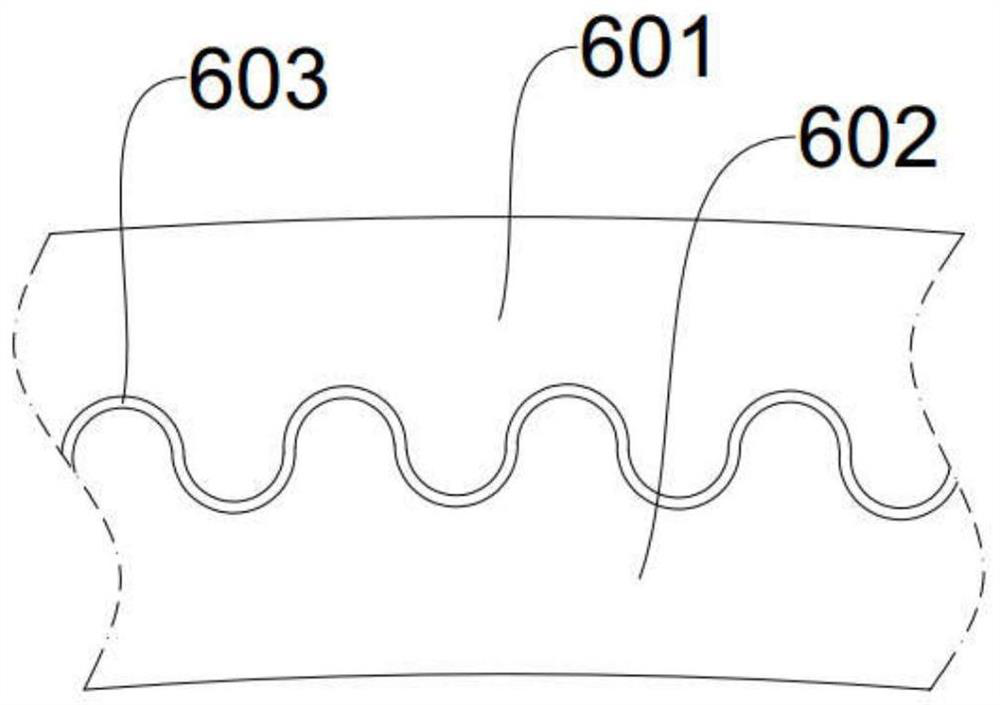

[0059] Core wire 1 group, tape layer 2, inner sheath 3, armor layer 5 and outer sheath 6 arranged in sequence from inside to outside;

[0060] The core wire group 1 is composed of several core wires 1. In this embodiment, the core wire group 1 is composed of three core wires 1, and the three core wires 1 are as follows: figure 1 As shown, it is evenly arranged in a triangular distribution along the circumferential direction of the cable axis, and a filler 4 is provided in the gap of the core wire group 1, and the filler 4 is a filler rope;

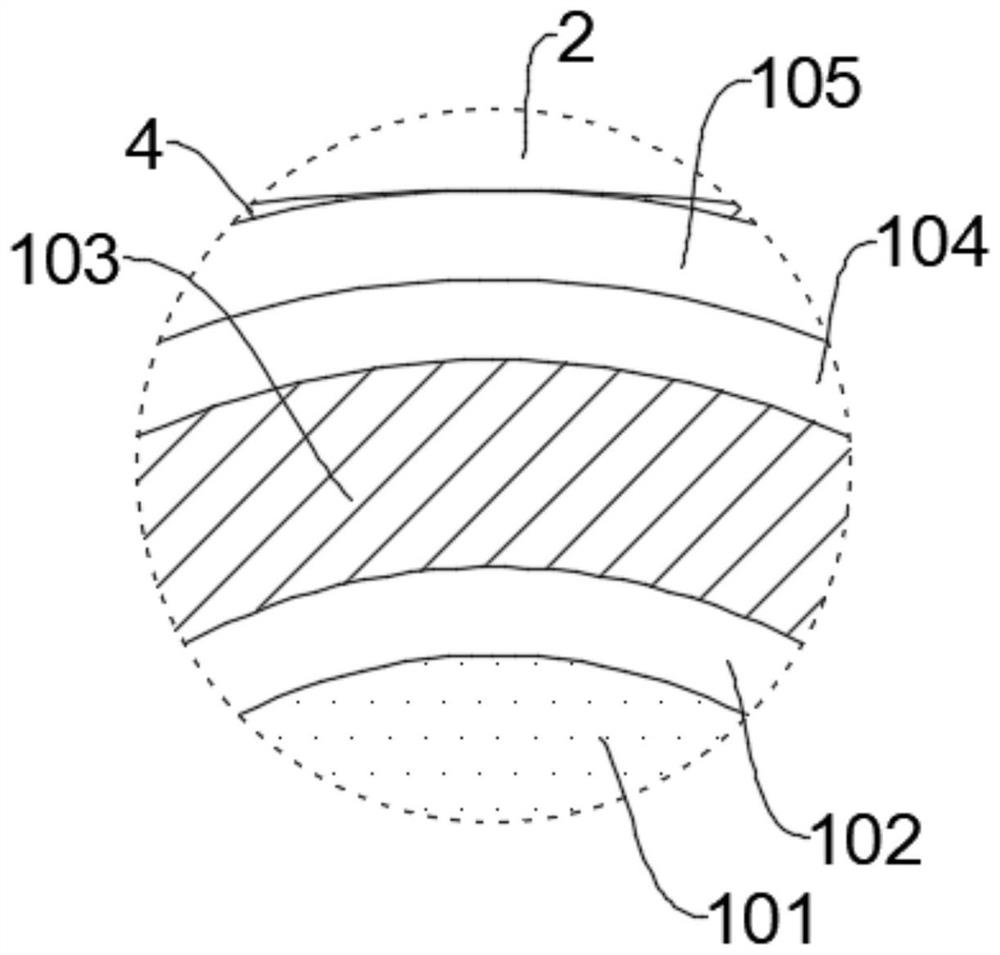

[0061] The core wire 1 includes a conductor 101, an inner shielding layer 102, a modified insulating layer 103, an insulating shielding layer 104 and a metal shielding layer 105 from the inside to the outside;

[0062] The conductor 101 is a common cable conductor 101, which can be stranded copper, single copper, copper...

Embodiment 2

[0087] In the ethylene-propylene rubber copolymer, Si-C-Al composite filler is further doped, and the addition amount of Si-C-Al composite filler is 12 to 15wt% of the ethylene-propylene rubber copolymer. The doping of composite fillers can further improve the thermal conductivity and heat dissipation performance of the modified insulating layer, and to a certain extent improve its insulation and electrical breakdown resistance;

[0088] The above-mentioned Si-C-Al composite filler is prepared by the following process:

[0089] Mix coke powder, aluminum powder and elemental silicon powder into a mixed powder, and control the mass ratio of coke powder, aluminum powder and elemental silicon powder in the mixed powder to 1: (1.9~2.1): (6.9~7.1), this implementation The mass ratio of coke powder, aluminum powder and elemental silicon powder used in the example is 1:2:7. After the above-mentioned mixture is uniformly mixed into a mixed powder, it is pressed to form a block material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com