Psyllium seed husk high-protein meal replacement powder, and preparation method thereof

A technology of psyllium husk and high protein, which is applied in the field of high-protein meal replacement powder of psyllium husk and its preparation, can solve the problems of uncoordinated flavor fusion, poor satiety, and poor brewability, etc. Achieve the effect of rich and full taste, strong satiety, and easy control of process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

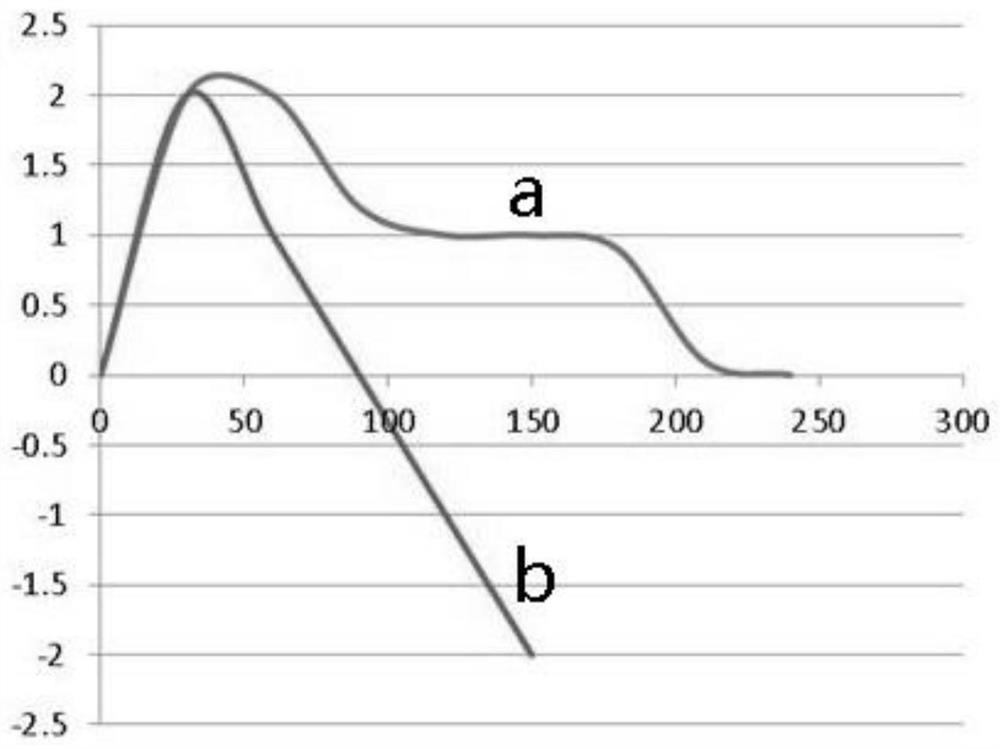

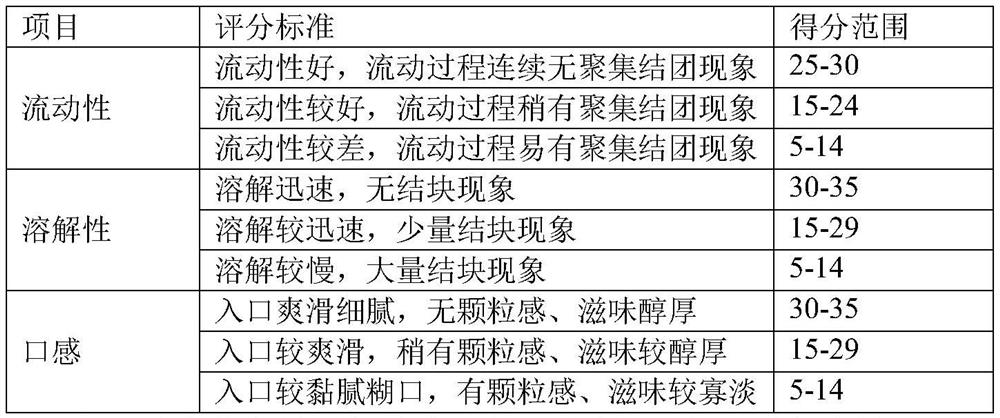

Image

Examples

Embodiment 1

[0038] A kind of plantain seed husk high-protein meal replacement powder, is made up of following components: psyllium seed husk powder 8g, concentrated milk protein 25g, soybean protein isolate 13g, skimmed milk powder 25g, resistant dextrin 3.5g, Polydextrose 3g, crystalline fructose 10g, MCT medium-chain fat powder 7g, gellan gum 0.7g, multivitamin 0.5g, multimineral 0.4g and food flavor 0.37g.

[0039] The preparation method of the above-mentioned plantain seed husk high-protein meal replacement powder comprises the following steps:

[0040] (1) According to the above ratio, boil and granulate concentrated milk protein, soybean protein isolate, crystalline fructose, and psyllium seed husk powder:

[0041] (a) Feeding stage: put the material into the granulator, set the atomization pressure to 5bar, the air inlet temperature to 65°C, and the air inlet speed to be controlled at 800m 3 / h;

[0042] (b) Preheating and mixing stage: atomization pressure 5bar, air inlet temper...

Embodiment 2

[0051] A high-protein meal replacement powder of psyllium husk, which consists of the following components: 5 g of psyllium husk powder, 10 g of resistant dextrin, 1 g of polydextrose, 15 g of MCT medium-chain fat powder, and 0.1 g of gellan gum g, 15g of crystalline fructose, 15g of concentrated milk protein, 25g of soy protein isolate, 0.1g of multivitamins and 1g of multivitamins.

[0052] The preparation method of the above-mentioned plantain seed husk high-protein meal replacement powder comprises the following steps:

[0053] (1) According to the above ratio, boil and granulate concentrated milk protein, soybean protein isolate, crystalline fructose, and psyllium seed husk powder:

[0054] (a) Feeding stage: put the material into the granulator, set the atomization pressure to 1bar, the inlet air temperature to 100°C, and the inlet air speed to be controlled at 10000m 3 / h;

[0055] (b) Preheating and mixing stage: atomization pressure 6bar, air inlet temperature 50°C,...

Embodiment 3

[0061] A high-protein meal replacement powder of psyllium husk, comprising the following components: 10 g of psyllium husk powder, 5 g of resistant dextrin, 2 g of polydextrose, 8 g of MCT medium-chain fat powder, 1 g of gellan gum, Crystalline fructose 8g, concentrated milk protein 20g, soybean protein isolate 15g, multivitamin 0.8g, multimineral 0.5g, skimmed milk powder 25g and food flavor 2g.

[0062] The preparation method of the above-mentioned plantain seed husk high-protein meal replacement powder comprises the following steps:

[0063] (1) According to the above ratio, boil and granulate concentrated milk protein, soybean protein isolate, crystalline fructose, and psyllium seed husk powder:

[0064] (a) Feeding stage: Put the material into the granulator, set the atomization pressure to 6bar, the air inlet temperature to 50°C, and the air inlet speed to be controlled at 10000m 3 / h;

[0065] (b) Preheating and mixing stage: atomization pressure 1bar, air inlet tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com