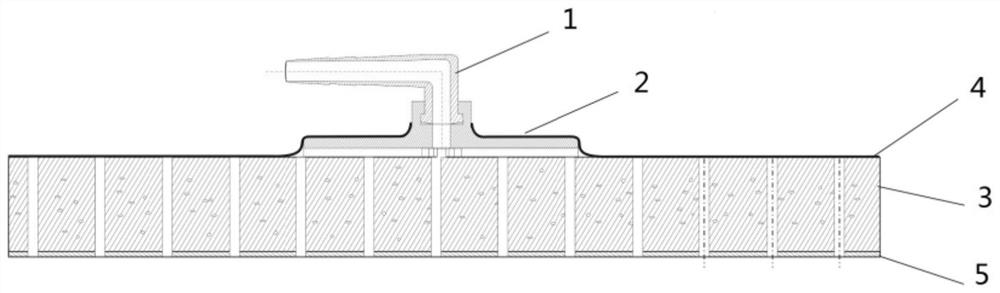

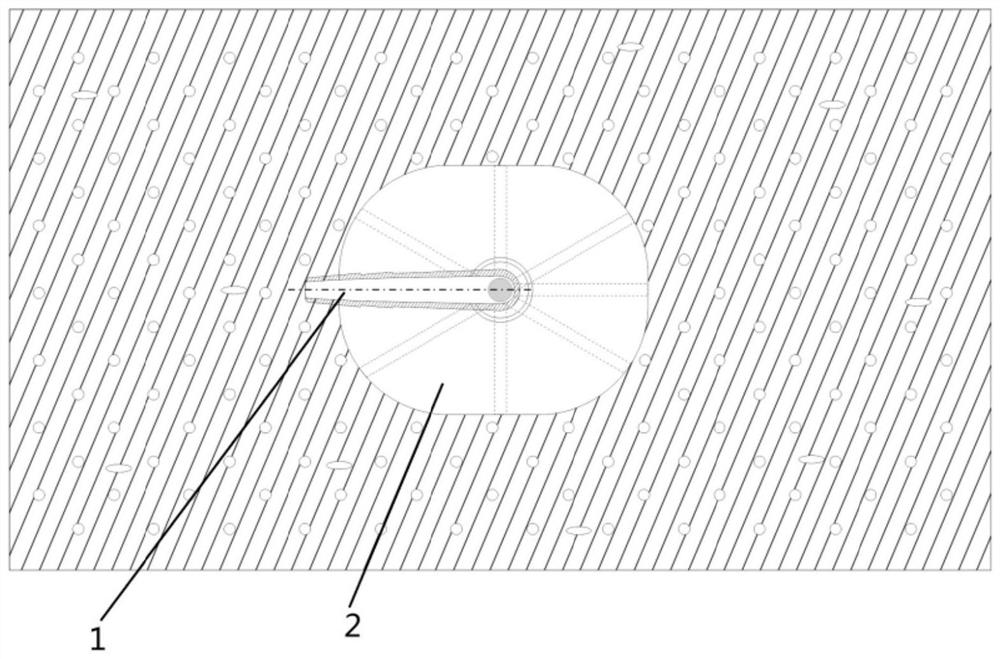

Composite dressing and negative pressure drainage device prepared therefrom

A solution and fiber mesh technology, applied in suction devices, bandages, drug delivery, etc., can solve the problems of high price, hardening, complicated porous structure process, etc., to overcome structural instability, high biological safety, and promote wound healing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S1. Mix the nano-silver solution with viscose fiber and elastic polyester staple fiber and put it into the cotton blender according to the mass ratio of 1:1, add 10mL of pullulan solution with a mass concentration of 1g / mL, and mix thoroughly for 30min , after mixing evenly, enter the double cylinder carding machine for carding, the carding speed is controlled at 20m / min, the cylinder interval is controlled at 25mm, and then the web is continuously laid to form a fiber web;

[0036] S2. Set low-melt polyester staple fibers on the fiber net, enter the upright cotton swing head, control the swing speed 40 times / min, fold the fiber net into an upright continuous stacking state to form multiple 3D upright cotton units next to each other , 3D upright cotton unit control 10cm;

[0037] S3. The 3D upright cotton unit obtained above was heated and formed in an oven, the heating time was 20 minutes, the baking temperature was 160°C, and the composite dressing was obtained by cut...

Embodiment 2

[0040] S1. Put the nano-silver solution in the viscose fiber and elastic polyester staple fiber and mix it into the cotton blender according to the mass ratio of 1:1.5, add 10mL of pullulan solution with a mass concentration of 1.5g / mL, and mix well 30min, after mixing evenly, enter the double cylinder carding machine for carding, the carding speed is controlled at 25m / min, the cylinder interval is controlled at 30mm, and then the web is continuously laid to form a fiber web;

[0041] S2. Set low-melt polyester staple fibers on the fiber net, enter the upright cotton swing head, control the swing speed 40 times / min, fold the fiber net into an upright continuous stacking state to form multiple 3D upright cotton units next to each other , 3D upright cotton unit control 10cm;

[0042] S3. The 3D upright cotton unit obtained above was heated and formed in an oven, the heating time was 25 minutes, the baking temperature was 170°C, and the composite dressing was obtained by cutting,...

Embodiment 3

[0045] S1. Mix the nano-silver solution with viscose fiber and elastic polyester staple fiber and put it into the cotton blender according to the mass ratio of 1:20, add 10mL of pullulan solution with a mass concentration of 2g / mL, and mix thoroughly for 30min , after mixing evenly, enter the double cylinder carding machine for carding, the carding speed is controlled at 25m / min, the cylinder interval is controlled at 30mm, and then the web is continuously laid to form a fiber web;

[0046] S2. Set low-melt polyester staple fibers on the fiber net, enter the upright cotton swing head, control the swing speed 40 times / min, fold the fiber net into an upright continuous stacking state to form multiple 3D upright cotton units next to each other , 3D upright cotton unit control 10cm;

[0047] S3. The 3D upright cotton unit obtained above was heated and formed in an oven, the heating time was 35 minutes, the baking temperature was 185°C, and the composite dressing was obtained by cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com