Sludge incineration flue gas emission up-to-standard control system and method

A technology for flue gas emission and sludge incineration, applied in combustion methods, separation methods, chemical instruments and methods, etc., can solve problems such as affecting the accuracy of pH value measurement, affecting the service life and measurement accuracy, affecting the desulfurization effect, etc. , to solve the unstable pH value measurement and the rapid aging of the instrument, the flue gas emission is completely controllable, and the effect of delaying the fouling and blocking cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

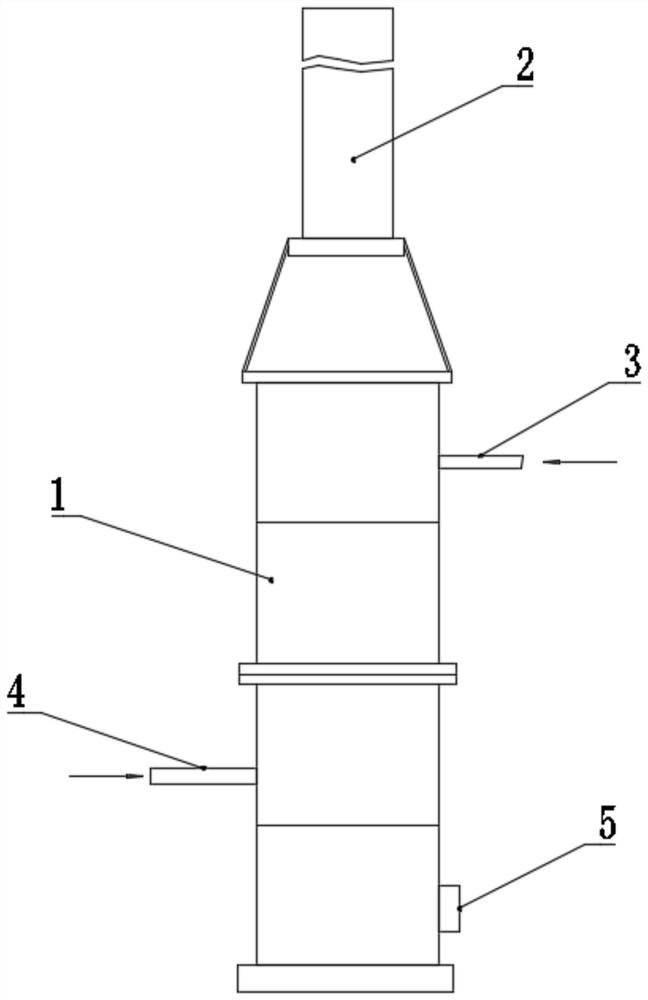

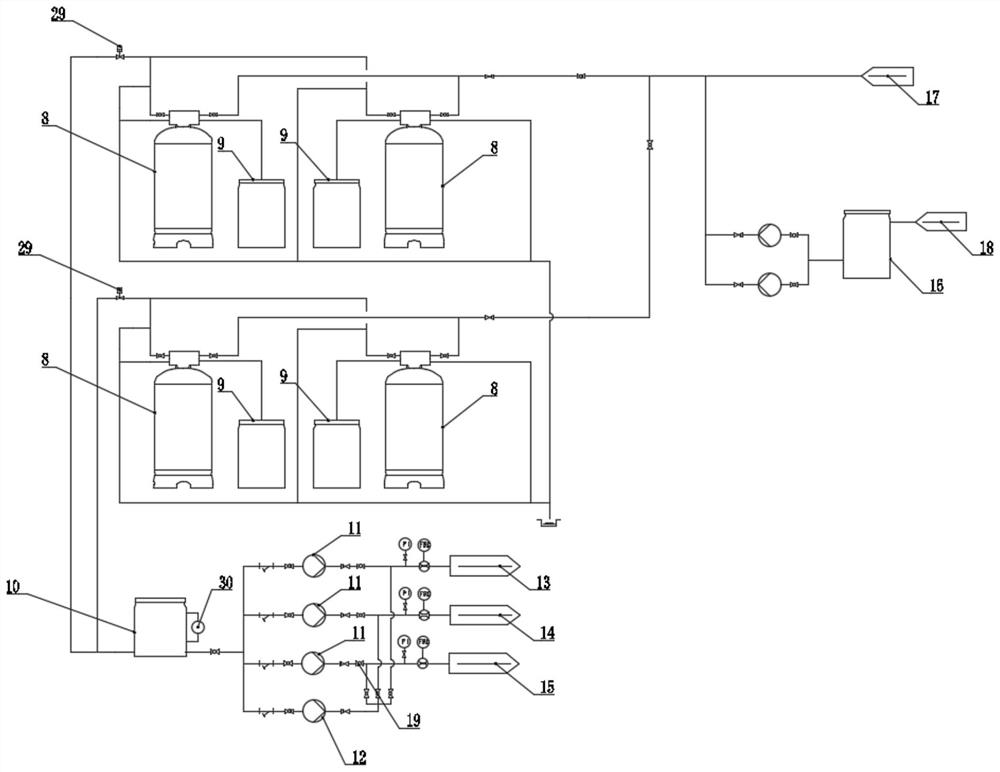

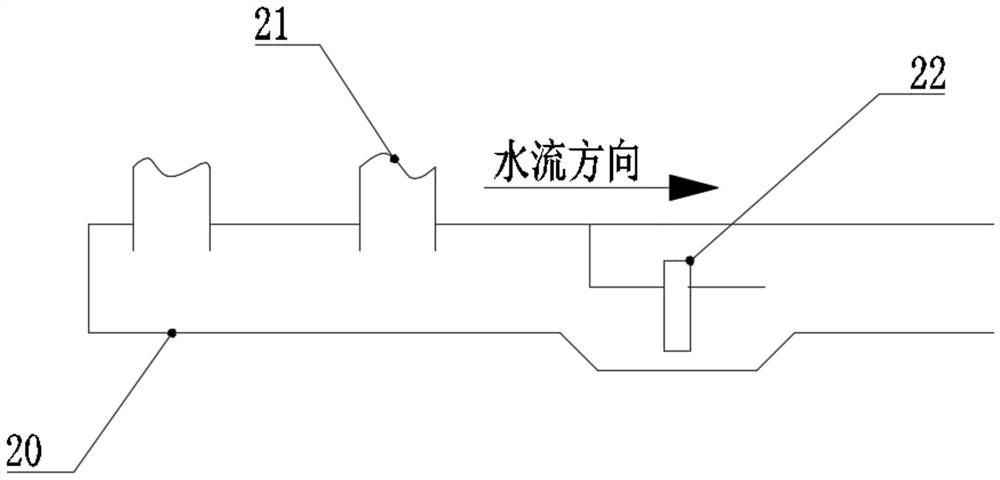

[0044] In this embodiment, a kind of sludge incineration flue gas emission compliance control system is specifically provided. The control system is mainly to control the flue gas emission of the wet tower 1. Therefore, the system is based on the wet tower 1 to improve and Optimized, from the overall technical background, in sludge incineration, including an incinerator, a sludge pretreatment machine for supplying sludge to the incinerator, and the incinerator produces a large amount of smoke when incinerating sludge gas, and these flue gases need to be treated by the wet process tower 1 (wet process desulfurization absorption tower) and then discharged into the air. controllable purpose. In the prior art, the wet tower 1 is equipped with a NaOH modulation tank for dropping into NaOH solution and a replenishment pipeline 3 for replenishing water, and the replenishment pipeline 3 supplements the circulating water for the wet tower 1. The working principle and operation itself ...

Embodiment 2

[0063] On the basis of Example 1, this embodiment also specifically provides a method for controlling the emission of flue gas from sludge incineration to reach the standard. The control realizes automatic and unmanned control, and the method includes:

[0064] (1) Soft water dosing

[0065] Configure the water softener for preparing soft water, put the softened water of the water softener into the soft water storage tank 10, supply soft water to the replenishment pipeline 3 of the NaOH conditioning tank and the wet process tower 1 through the soft water storage tank 10, and supply the soft water to the wet process tower through the NaOH conditioning tank 1 Put in NaOH solution; in order to further realize the fully automatic dosing of soft water, the following control logic is adopted:

[0066]①Install a soft water outlet valve 29 between the water softener and the soft water storage tank 10 and set a first liquid level gauge 30 in the soft water storage tank 10, and measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com