Method for extracting tea seed oil

A technology of tea seed oil and camellia oleifera, which is applied in the field of vegetable oil extraction, can solve the problems of low extraction efficiency of tea seed oil and affect the output of tea seed oil, etc., and achieve the improvement of ultrasonic cavitation, the efficiency of ultrasonic wall breaking, and the expansion of bubbles Effect of speed and amount of bubble generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

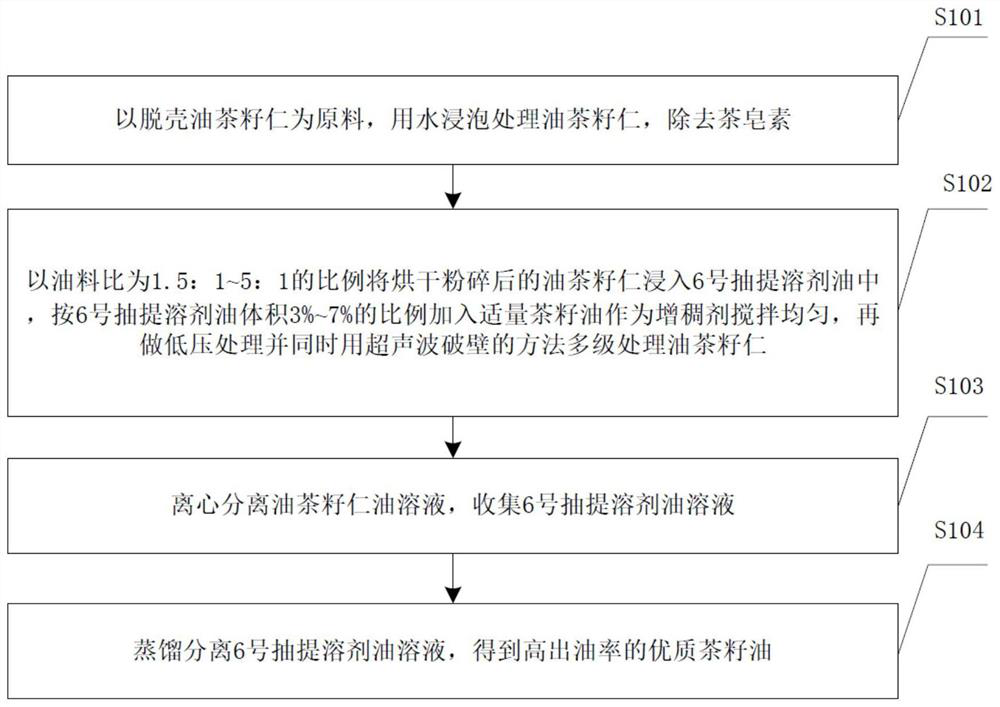

[0026] Embodiment: Take 100 kg of dehulled camellia oleifera seed kernels containing 50.2% oil as raw material, use water as soaking agent, and ultrasonically soak the camellia oleifera kernels under normal temperature conditions to remove tea saponin. Ultrasonic the Camellia oleifera seed aqueous solution for 20-25 minutes every hour, change the water every 5 times of ultrasound, change the water three times in total, remove the soaking water, collect the Camellia oleifera seed kernel, dry and pulverize the Camellia oleifera seed kernel;

[0027] Immerse the dried and pulverized Camellia oleifera seed kernels in No. 6 extraction solvent oil at a ratio of 4:1 to the oil-plant ratio, and add tea seed oil as a thickener at a ratio of 3.5% of the volume of No. 6 extraction solvent oil and stir evenly. Then do low-pressure treatment and process the Camellia oleifera seed kernel with the method of ultrasonic wall breaking at the same time, do first-level ultrasonic wall breaking tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com