Tunnel blasting intelligent hole distribution method

A tunnel and hole-laying technology, which is applied in blasting and other directions, can solve the problems of increasing the difficulty and cost of support construction, the mechanism of blasting action is not deep enough, and the rock cannot be broken efficiently, so as to achieve the overall blasting effect is safe and stable, easy to operate and load, The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

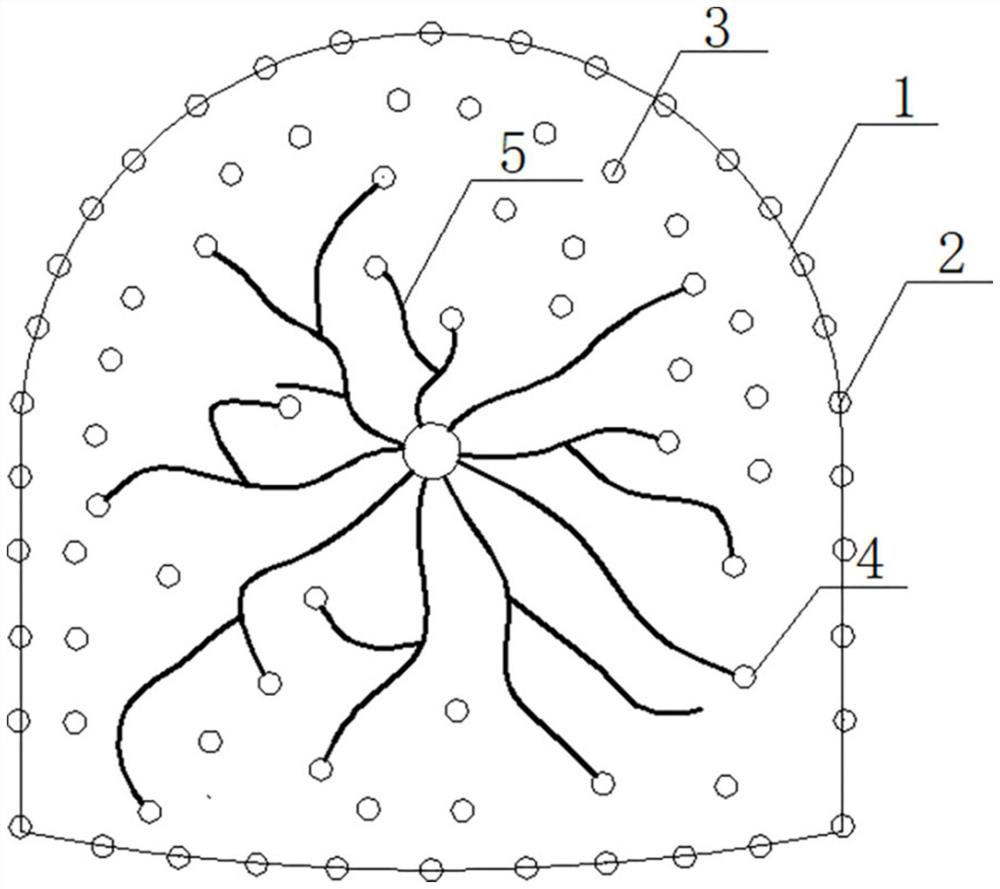

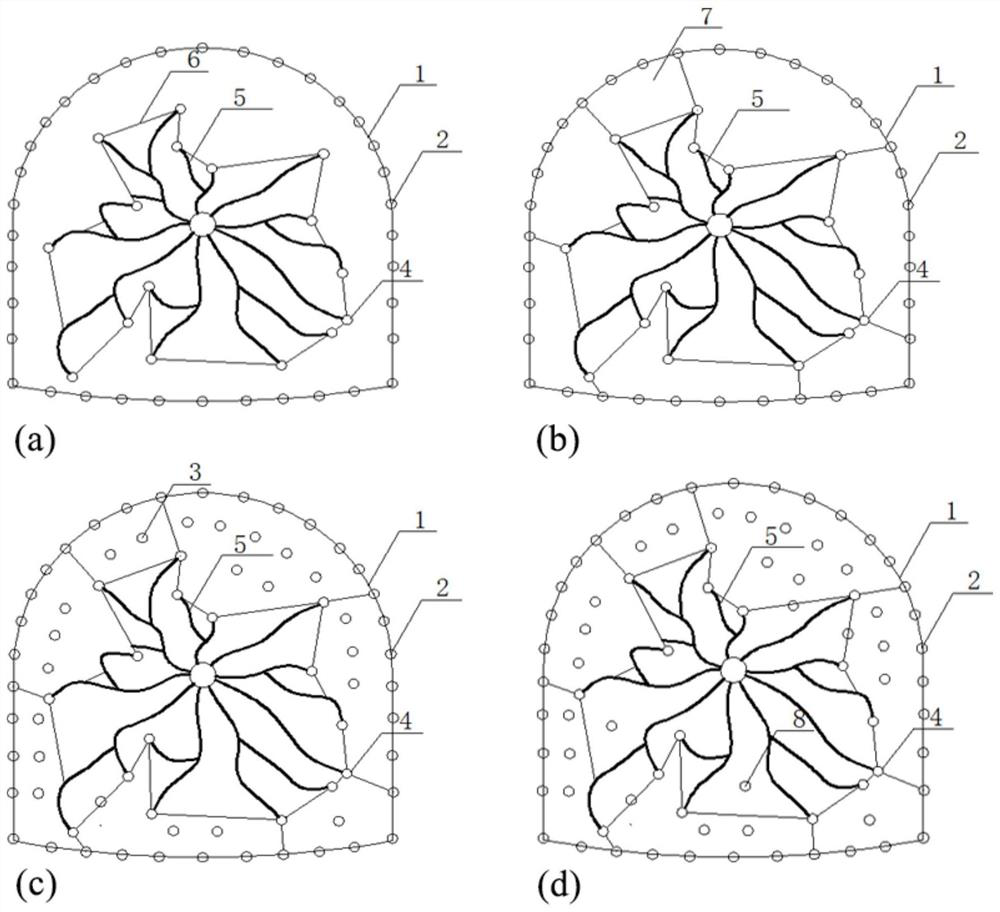

[0033] Such as figure 1 As shown, a tunnel blasting intelligent hole layout method comprises the following steps:

[0034] (1) Peripheral hole 1 and positioning hole 11 are drilled, and positioning hole 11 is located at the centroid center of the excavation surface. Specifically, the cross method can be used for positioning;

[0035] (2) Next, the peripheral eye 1 and the positioning eye 11 are blasted. For the peripheral eye 1, the charge is blasted on a smooth surface, using an uncoupled charge structure; Blasting can effectively form rock cracks 5 around the positioning hole 11, which are used for the layout of the rear cutting hole 4 and auxiliary hole 3; the hole diameter of the positioning hole 11 is about 2 to 3 times that of the peripheral hole 1, and the specific needs are based on the nature of the rock mass. Make corresponding adjustments; when blasting, blast the peripheral eye 1 first, and then blast the positioning eye 11;

[0036] (3) Next, accurately locate t...

Embodiment 2

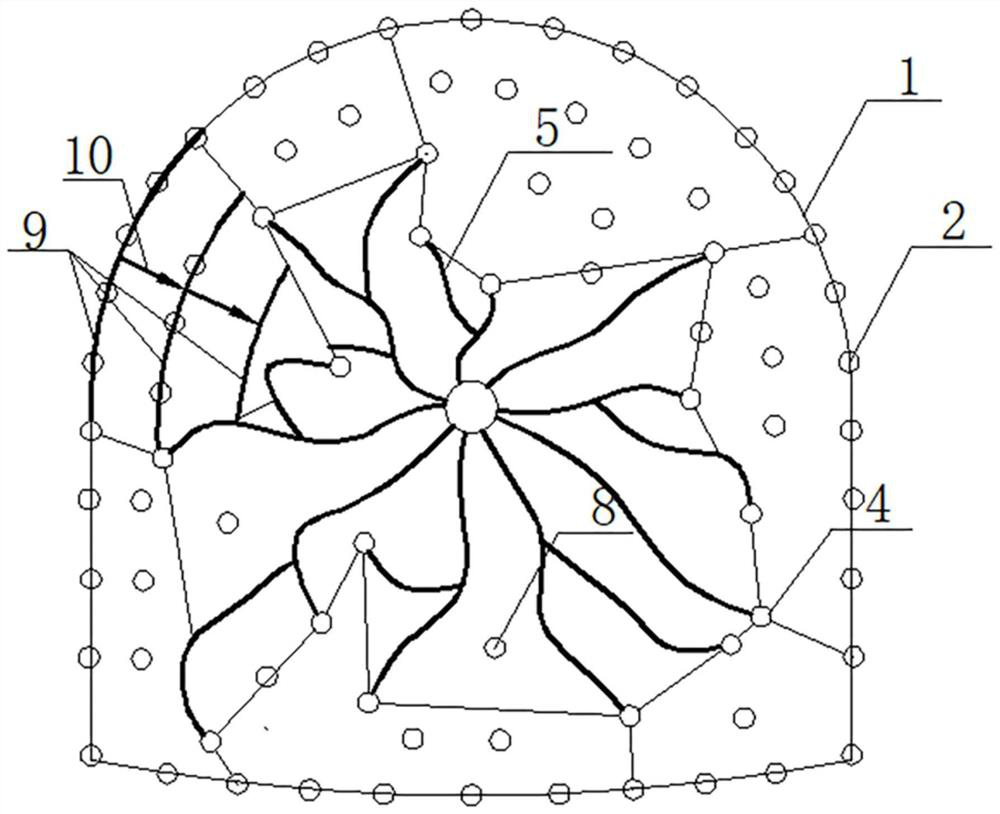

[0041] Such as Figure 4 As shown, it is basically the same as Embodiment 1, the difference is: when the tunnel width is too wide or the height is too high, when the blasting design is carried out, the tunnel plane is divided into different divisional surface blocks 12, and each divisional surface block 12 All can be regarded as a separate tunnel blasting excavation surface, the peripheral eyes are arranged according to the largest outer circle, and the positioning eyes 11 are arranged according to the particle centers of the divided surface blocks 12 . During the blasting, the blasting of the peripheral eye 1 is first carried out, and the positioning eye 11 is blasted in the order from top to bottom. For the upper positioning eye 11, the completion of the blasting of the lower positioning eye 11 is equivalent to forming the free surface. For different division surface blocks 12 The connection area of the 12 can better form the extended crack 5, the layout of the cut hole 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com