Method for determining allowable value of interlayer tensile stress design of airplane composite material

A composite material layer and tensile stress technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve low test efficiency, low calculation accuracy of interlayer tensile stress design allowable value, high test cost, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

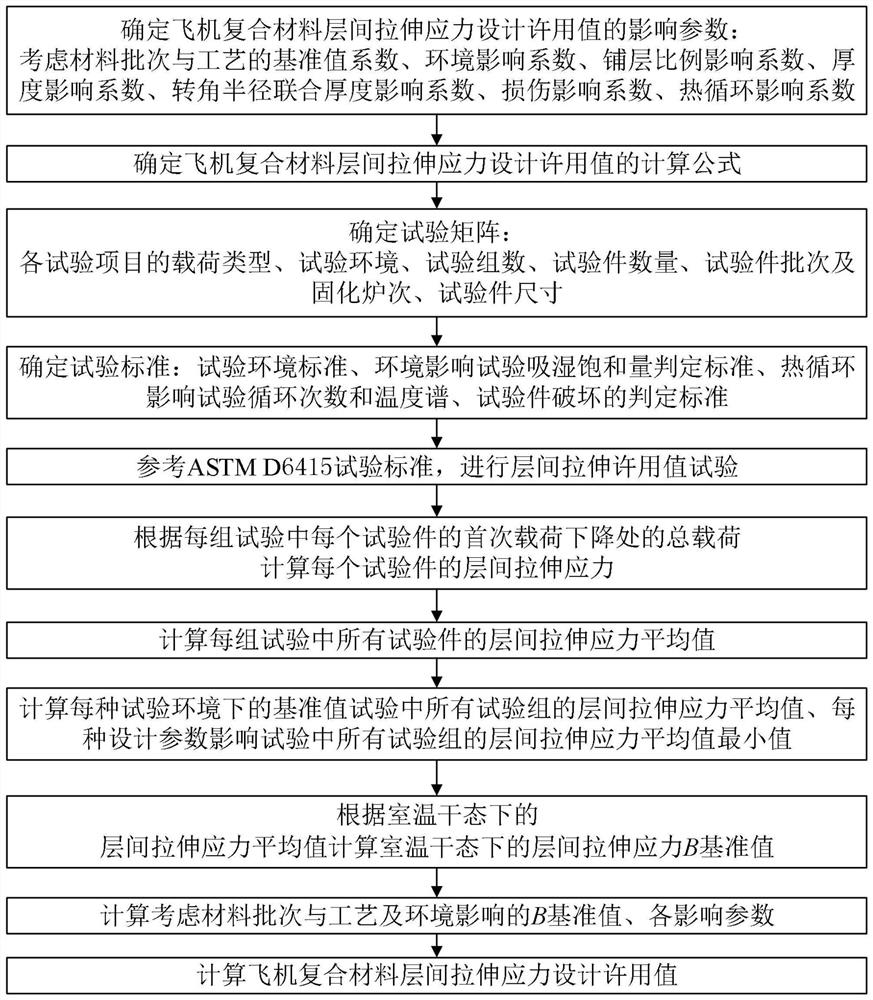

[0087] Such as figure 1 As shown, the method for determining the design allowable value of tensile stress between aircraft composite layers of the present invention comprises the following steps:

[0088] Step 1: Investigate the structural design, manufacturing and service data of relevant types of civil aircraft composite materials, and determine the influencing parameters of the design allowable value of interlayer tensile stress of aircraft composite materials, including B reference value coefficient k that considers material batches and processes b , Environmental impact coefficient k ekdf , ply ratio influence coefficient C layup , Thickness influence coefficient C t , Corner radius joint thickness influence coefficient C r / t , damage influence coefficient C d , thermal cycle influence coefficient C tc .

[0089] Composite material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com