Ball grid array millimeter wave broadband matching structure in wafer level packaging and design method

A wafer-level packaging, ball grid array technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as signal line mismatch, and achieve the effect of keeping impedance unchanged, achieving impedance matching, and achieving broadband matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

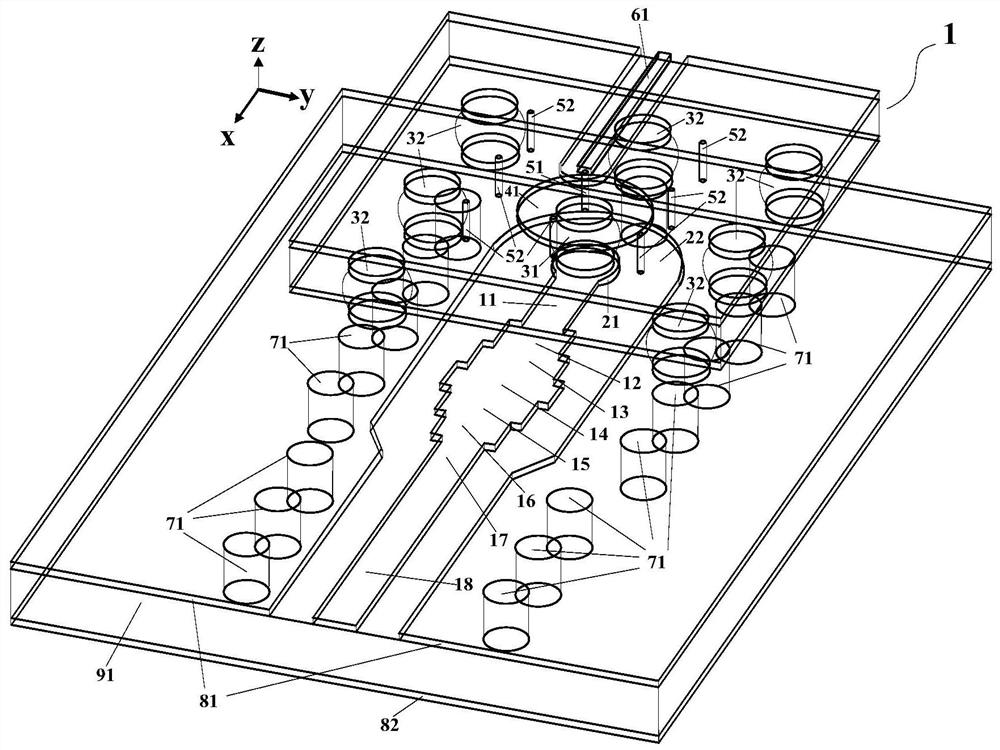

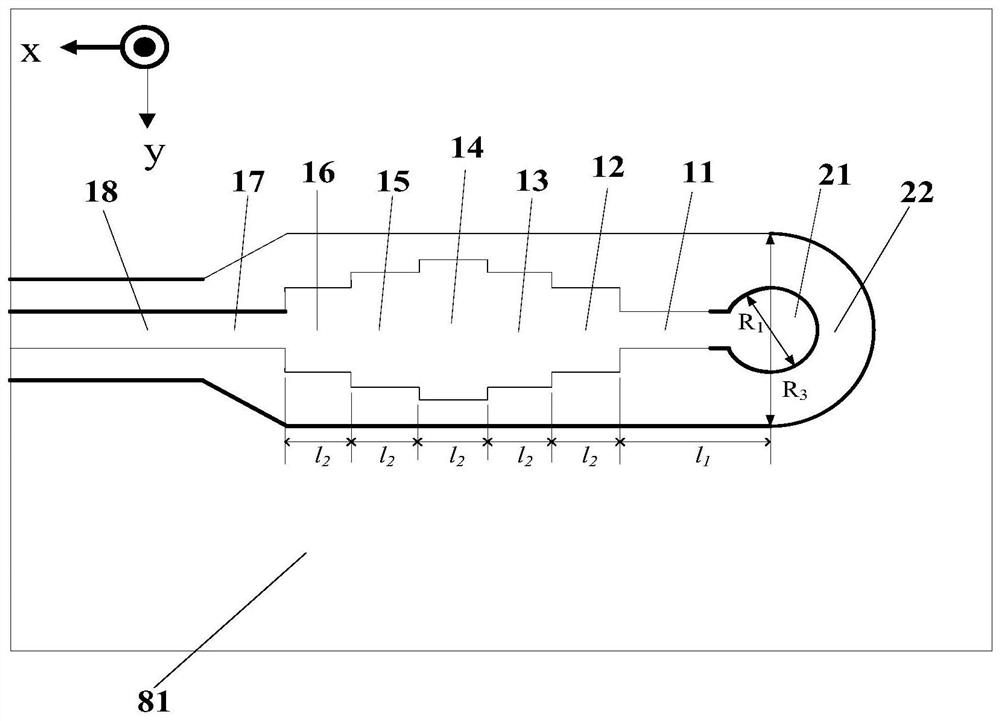

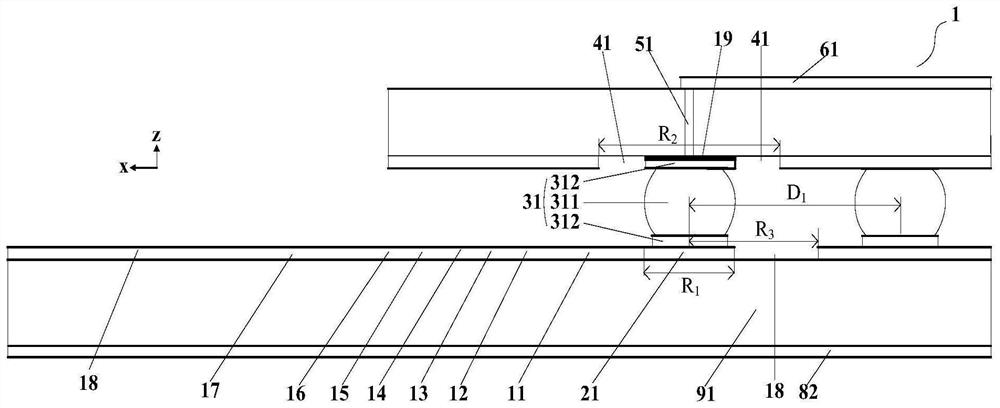

[0055] Such as figure 1 and figure 2 As shown, a ball grid array millimeter-wave broadband matching structure in a wafer-level package includes a silicon-based chip 1, a microwave dielectric substrate 91, metal ground plates 81 on both sides of the upper surface of the microwave dielectric substrate 91, and a microwave dielectric substrate 91. The lower metal ground plate 82 on the lower surface is used to connect the metal ground plates 81 on both sides with the metal via holes 71 of the lower metal ground plate 82 , the circular metal plate 21 and the semicircular gap 22 on the upper surface of the microwave dielectric substrate 91 .

[0056] Such as figure 2 As shown, the upper surface of the microwave dielectric substrate 91 is sequentially connected to the signal line of the first branch 11, the signal line of the second branch 12, the signal line of the third branch 13, the signal line of the fourth branch 14, and the fifth branch along the positive direction of the x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com