Lithium iron phosphate cathode slurry of lithium ion battery, preparation method of lithium iron phosphate cathode slurry and cathode pole piece

A lithium-ion battery and lithium iron phosphate technology, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems that lithium iron phosphate active materials are not easy to disperse, and achieve easy dispersion processing, low viscosity, and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

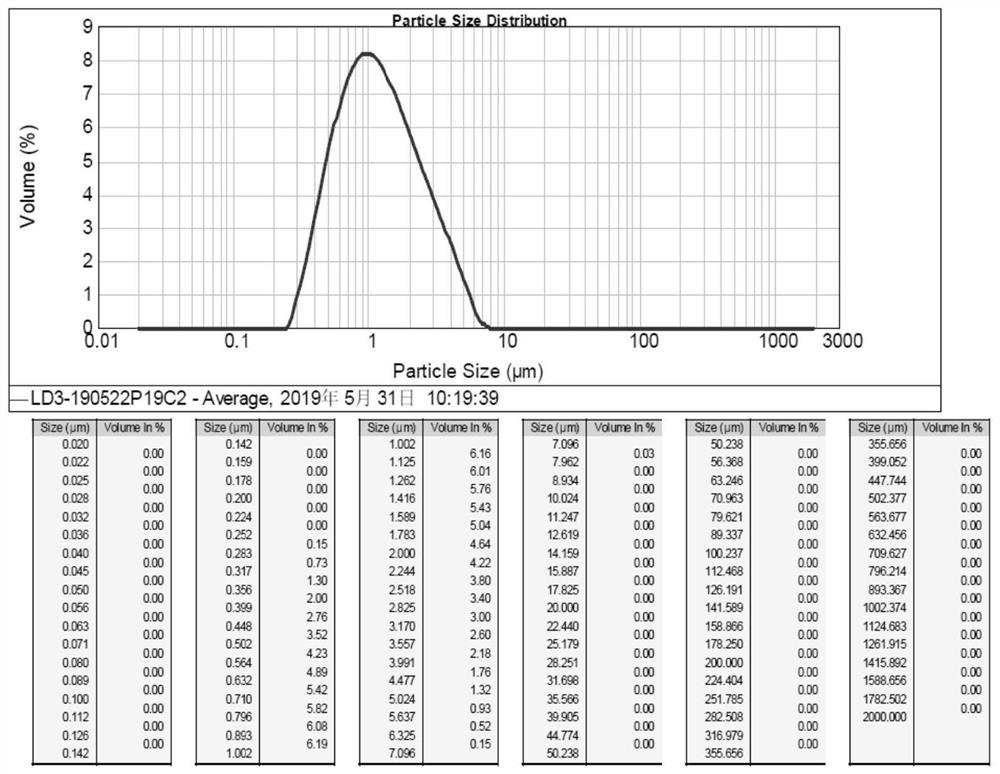

Image

Examples

Embodiment 1

[0053] A lithium iron phosphate positive electrode slurry for a lithium ion battery of the present embodiment has the following formula (each component is in parts by mass):

[0054] Lithium iron phosphate (specific surface area is 8.68m 2 / g) 93 parts;

[0055] 2 parts of 15% acrylate multipolymer solution (substitution degree 1.73);

[0056] 3 parts of polyacrylic resin emulsion;

[0057] 2 parts of SP-Li;

[0058] Among them, the tap density of lithium iron phosphate is 0.92g / cm 3 ; The pH value of the 15% acrylate multi-polymer solution is 6.86, and the viscosity is 2340mPa·S; the specific surface area of SP-Li is 58m 2 / g; During use, 2 parts of 15% acrylate multipolymer solution and 3 parts of polyacrylic resin emulsion are mixed into binder.

[0059] According to the above formula, the preparation method of a lithium iron phosphate positive electrode slurry for a lithium ion battery in this embodiment comprises the following steps:

[0060] (1) Preparation of co...

Embodiment 2

[0065] A lithium iron phosphate positive electrode slurry for a lithium ion battery of the present embodiment has the following formula (each component is in parts by mass):

[0066] Lithium iron phosphate (specific surface area is 8.52m 2 / g) 95 parts;

[0067] 1 part of 15% acrylate multi-polymer copolymer solution (substitution degree 1.73);

[0068] 3 parts of polyacrylic resin emulsion;

[0069] 1 part of SP-Li;

[0070] Among them, the tap density of lithium iron phosphate is 0.93g / cm 3 ; The pH value of the 15% acrylate multi-polymer solution is 6.86, and the viscosity is 2340mPa·S; the specific surface area of SP-Li is 58m 2 / g. When using, mix 1 part of 15% acrylate multi-polymer copolymer solution and 3 parts of polyacrylic resin emulsion into adhesive.

[0071] The preparation method of a lithium iron phosphate positive electrode slurry for a lithium ion battery in this embodiment comprises the following steps:

[0072] (1) Preparation of conductive glue: T...

Embodiment 3

[0077] A lithium iron phosphate positive electrode slurry for a lithium ion battery of the present embodiment has the following formula (each component is in parts by mass):

[0078] Lithium iron phosphate (specific surface area is 9.03m 2 / g) 97 parts;

[0079] 1 part of 15% acrylate multi-polymer copolymer solution (substitution degree 1.73);

[0080] 1 part of polyacrylic resin emulsion;

[0081] 1 part of SP-Li;

[0082] Among them, the tap density of lithium iron phosphate is 0.92g / cm 3 ; The pH value of the 15% acrylate multi-polymer solution is 6.86, and the viscosity is 2340mPa·S; the specific surface area of SP-Li is 58m 2 / g, pH 9.03. When using, mix 1 part of 15% acrylate multipolymer solution and 1 part of polyacrylic resin emulsion to form a binder.

[0083] The preparation method of a lithium iron phosphate positive electrode slurry for a lithium ion battery in this embodiment comprises the following steps:

[0084] (1) Preparation of conductive glue: Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com