Preparation method for wheat bran dietary fiber

A wheat bran and dietary fiber technology, applied in the field of food processing, can solve problems such as unfavorable industrialization, low product activity, lack of combination, etc., and achieve the effects of improving physiological activity, increasing extraction rate, and preventing and treating obesity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

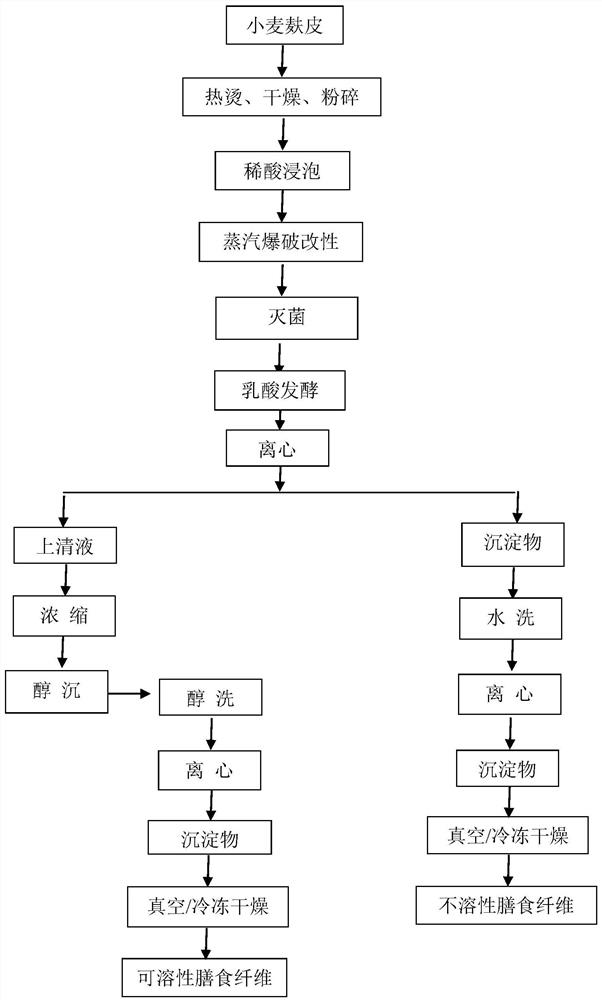

Image

Examples

Embodiment 1

[0030] (1) Blanching of raw materials: Wheat bran is obtained by cleaning the remaining by-products after wheat processing. The scalding temperature is 90°C for 5 minutes. After draining the blanched wheat bran, put it into a 75°C electric heater Dried 20h in the blast oven, its water content is 6%, it is pulverized to 80 orders, obtains the wheat bran powder of pretreatment, the mixing ratio of powder and sulfuric acid is 1g:3mL, and sulfuric acid concentration is 0.4% (v / v), the soaking temperature is 80°C, the soaking time is 5min, the acid hydrolysis solution is filtered off, and the humidity of the skin dregs is 55%;

[0031] (2) steam explosion modification: steam explosion treatment is carried out on the leather dregs particles obtained in step (1), the steam explosion pressure is 3.0MPa, the pressure holding time is 15min, and the steam explosion temperature is 150°C, so that the material is slurried;

[0032] (3) Sterilization: sterilize the material in step (2) at 9...

Embodiment 2

[0041] (1) Blanching of raw materials: Wheat bran is obtained by cleaning the remaining by-products after wheat processing. The scalding temperature is 95°C and the time is 6 minutes. Dried for 30h in a blast drying oven, its water content was 5%, and it was pulverized to 100 mesh to obtain pretreated wheat bran powder. The mixing ratio of powder and sulfuric acid was 1g:5mL, and the sulfuric acid concentration was 1.5% (v / v), the soaking temperature is 85°C, the soaking time is 4min, the acidolysis solution is filtered off, and the humidity of the skin dregs is 70%;

[0042] (2) steam explosion modification: the skin slag particles obtained in step (1) are subjected to steam explosion treatment, the steam explosion pressure is 0.5MPa, the pressure holding time is 18min, and the steam explosion temperature is 120°C to make the material slurry;

[0043] (3) Sterilization: sterilize the material in step (2) at 100° C. for 30 minutes, and cool to room temperature;

[0044] (4) ...

Embodiment 3

[0052] (1) Hot blanching of raw materials: Wheat bran is obtained by cleaning the remaining by-products after wheat processing. The blanching temperature is 100°C, and the time is 1min. Dried 24h in blast oven, its water content is 5%, it is pulverized to 80 order, obtains the wheat bran powder of pretreatment, the mixing ratio of powder and sulfuric acid is 1g:4mL, and sulfuric acid concentration is 0.9% (v / v), the soaking temperature is 75°C, the soaking time is 5min, the acidolysis solution is filtered off, and the humidity of the skin dregs is 45%;

[0053] (2) steam explosion modification: steam explosion treatment is carried out to the hide slag particles obtained in step (1), the steam explosion pressure is 2.0MPa, the pressure holding time is 20min, and the steam explosion temperature is 140°C, so that the material is slurried;

[0054] (3) Sterilization: The material in step (2) was sterilized at 120° C. for 25 minutes, and cooled to room temperature.

[0055] (4) F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com