A kind of rare earth garnet scintillation crystal and its production method

A technology of scintillation crystals and production methods, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of low transparency, low density of rare earth garnet scintillation crystals, poor chemical stability, etc., and achieve high melting point and radiation conversion Effects of efficiency, good chemical and photochemical stability, ease of doping with rare earth ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

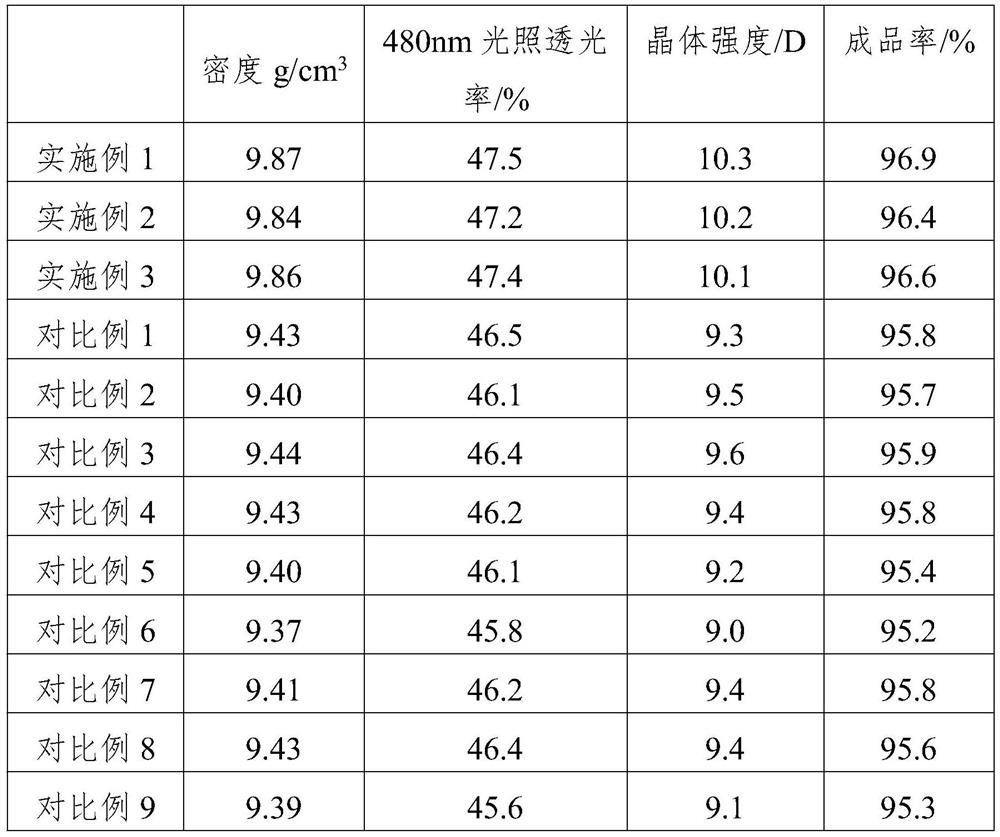

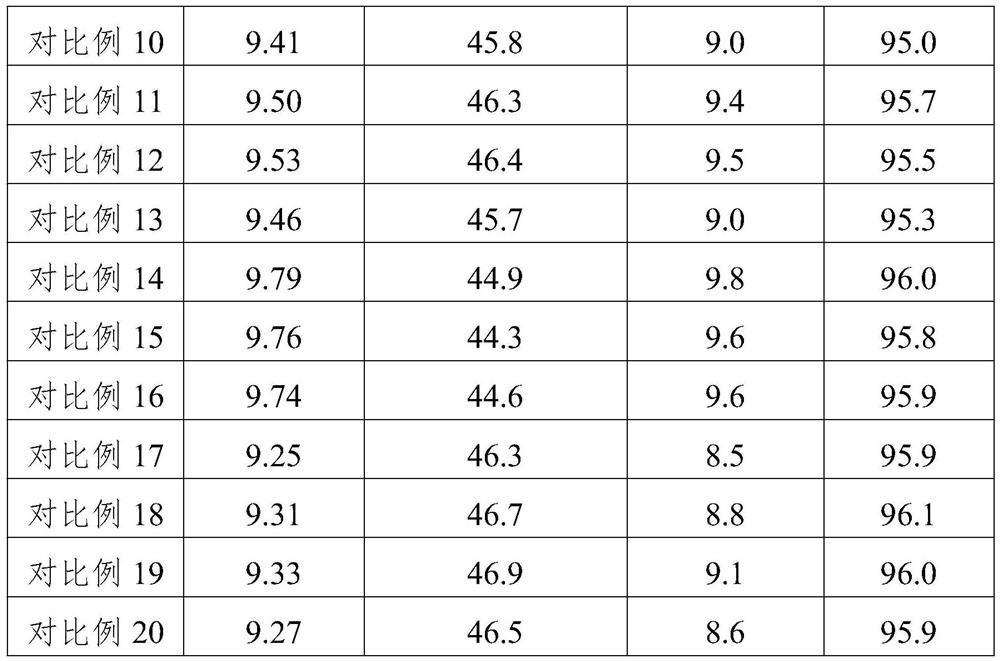

Examples

Embodiment 1

[0028] A rare earth garnet scintillation crystal, which has the following chemical formula: Y 3 sc 2 Al 3 o 12 ;

[0029] Wherein, the effective segregation coefficient of Y in the rare earth garnet scintillation crystal is 0.31, the effective segregation coefficient of Sc is 0.33, and the effective segregation coefficient of Al is 0.38.

[0030] A kind of production method of rare earth garnet scintillation crystal comprises the following steps:

[0031] S1: Weigh 1250g Y in proportion 2 o 3 , 1250g Sc 2 o 3 and 700g Al 2 o 3 , and add 75g of sintering aid, after mixing evenly, raise the temperature to 1425°C at a heating rate of 5°C / min and keep it warm for 1.25h to obtain a mixed powder;

[0032] Among them, the sintering aid is made of the following percentages of raw materials: SiO 2 The mass fraction of MgO accounts for 60%, and the mass fraction of MgO accounts for 40%;

[0033] S2: The mixed powder is made into 40mm particles, and then isostatically pressed...

Embodiment 2

[0036] A rare-earth garnet scintillation crystal with the following chemical formula: Cd 3 sc 2 Ga 3 o 12 ;

[0037] Wherein, the effective segregation coefficient of Cd in the rare earth garnet scintillation crystal is 0.3, the effective segregation coefficient of Sc is 0.33, and the effective segregation coefficient of Ga is 0.36.

[0038] A kind of production method of rare earth garnet scintillation crystal comprises the following steps:

[0039] S1: Weigh 1000g Cd in proportion 2 o 3 , 1000g Sc 2 o 3 and 500g Ga 2 o 3, and add 50g of sintering aid, after mixing evenly, raise the temperature to 1400°C at a heating rate of 5°C / min and keep it warm for 1h to obtain a mixed powder;

[0040] Among them, the sintering aid is made of the following percentages of raw materials: SiO 2 The mass fraction of MgO accounts for 55%, and the mass fraction of MgO accounts for 35%;

[0041] S2: The mixed powder is made into 35mm particles, and then isostatically pressed under a...

Embodiment 3

[0044] A rare-earth garnet scintillation crystal with the following chemical formula: Lu 3 sc 2 In 3 o 12 ;

[0045] Wherein, the effective segregation coefficient of Lu in the rare earth garnet scintillation crystal is 0.32, the effective segregation coefficient of Sc is 0.33, and the effective segregation coefficient of In is 0.4.

[0046] A kind of production method of rare earth garnet scintillation crystal comprises the following steps:

[0047] S1: Weigh 1500g Lu in proportion 2 o 3 , 1500g Sc 2 o 3 and 900g In 2 o 3 , and add 100g of sintering aid, after mixing evenly, raise the temperature to 1450°C at a heating rate of 5°C / min and keep it warm for 1.5h to obtain a mixed powder;

[0048] Among them, the sintering aid is made of the following percentages of raw materials: SiO 2 The mass fraction of MgO accounts for 65%, and the mass fraction of MgO accounts for 45%;

[0049] S2: The mixed powder is made into 45mm particles, and then isostatically pressed und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com