Solvent recovery system and method for isopropanol urea dewaxing process

A urea dewaxing and recovery system technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve problems such as personal injury and environmental pollution, achieve high recovery rate and reduce energy consumption , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

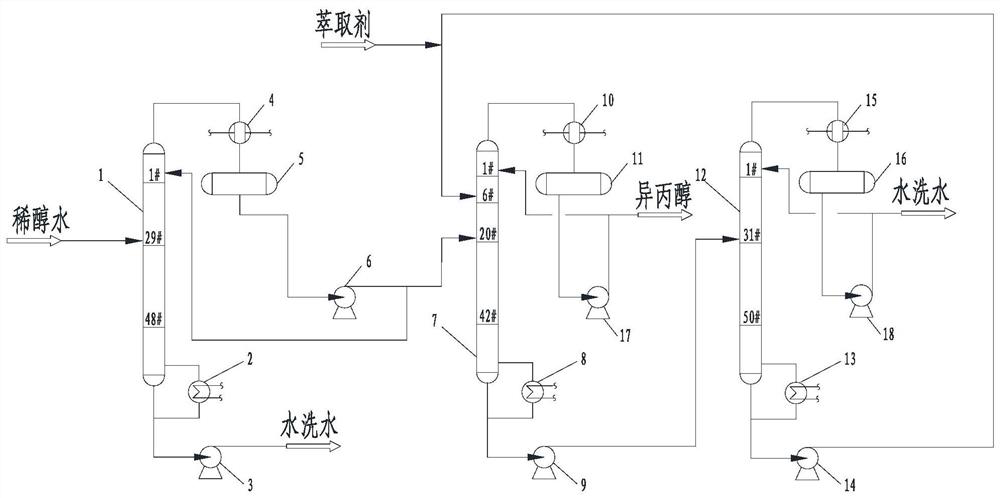

[0033] A solvent recovery system for the isopropanol urea dewaxing process, including an alcohol concentration tower, an extractive distillation tower and a solvent recovery tower connected in sequence; the alcohol concentration tower includes a tower body I1, and a cooler is connected to the top of the tower body I1 in sequence Ⅰ4, reflux tank Ⅰ5, reflux pump 6, the bottom of tower body Ⅰ1 is connected with reboiler Ⅰ2 and tower bottom pump Ⅰ3 in turn; the extractive distillation tower includes tower body Ⅱ7, and the top of tower body Ⅱ7 is connected with cooler Ⅱ10 and reflux tank Ⅱ11 in sequence , reflux pump 17, reboiler Ⅱ8 and tower bottom pump Ⅱ9 are successively connected to the bottom of tower body Ⅱ7; solvent recovery tower includes tower body Ⅲ12, and the top of tower body Ⅲ12 is connected to cooler Ⅲ15, reflux tank Ⅲ16, reflux pump 18, tower The bottom of body III12 is successively connected with reboiler III13 and tower bottom pump III14; the alcohol concentration t...

Embodiment 2

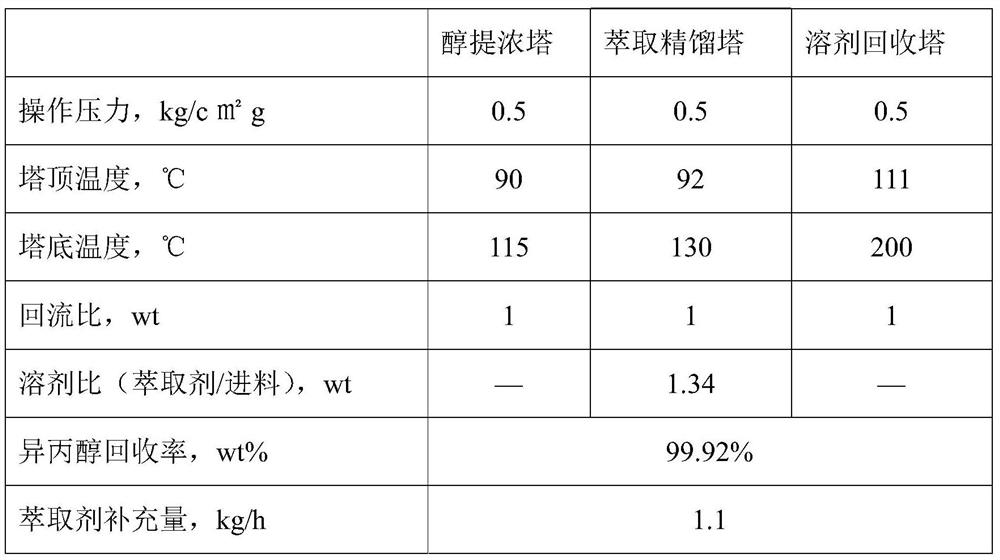

[0035] For the process flow of the alcohol recovery unit of a 100,000 tons / year isopropanol urea dewaxing unit, see figure 1 , the alcohol concentration tower has 48 layers of trays, the extractive distillation tower has 42 layers of trays, and the solvent recovery tower has 50 layers of trays, and the concentration is the mixture of 12.7%wt isopropanol and water (flow 25t / h, temperature 40 ℃) into the alcohol concentration tower 1, obtain about 86.1%wt isopropanol aqueous solution (flow 3.737t / h, temperature 40 ℃) at the tower top, obtain the water of purity 99.99%wt (flow 21.627t / h) at the bottom of the tower Sent to the washing unit for recycling. The top product of the alcohol concentration tower is sent to the extractive distillation tower 7, enters in the 20th tray of the extractive distillation tower, further concentrates, and injects the extractant ethylene glycol at the 6th tray of the extractive distillation tower 7 Alcohol, the isopropanol (flow rate 3.288t / h) of 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com