An energy-saving straw decomposition machine with automatic control of the distance between grinding discs and its control method

A technology of decomposing machine and moving grinding disc, which is applied in mechanical/thermomechanical pulp, textiles, papermaking, papermaking, etc. It can solve the problems of high power consumption and heavy motor load, and achieve the effects of simple structure design, improved quality and stable current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

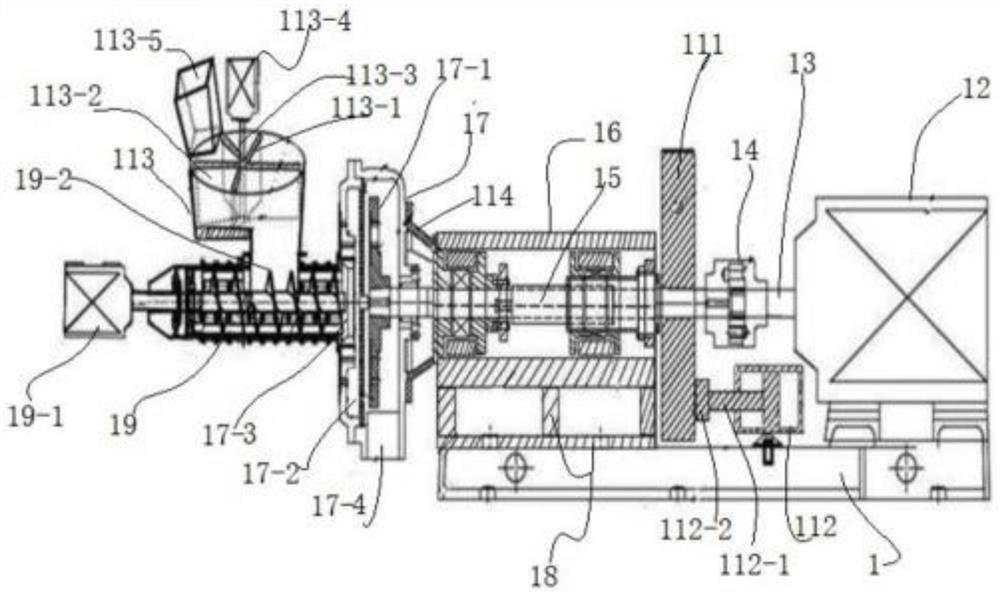

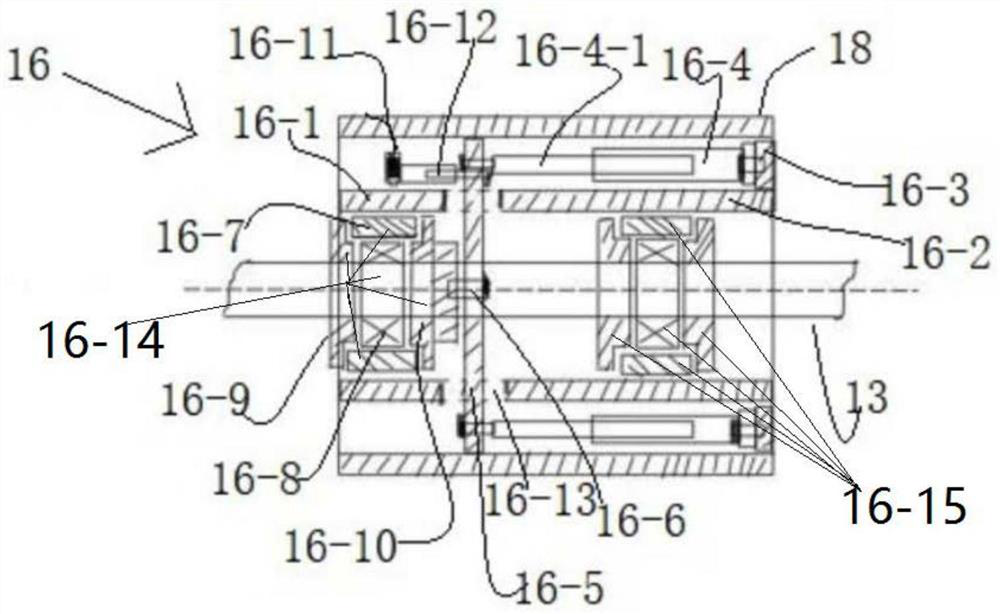

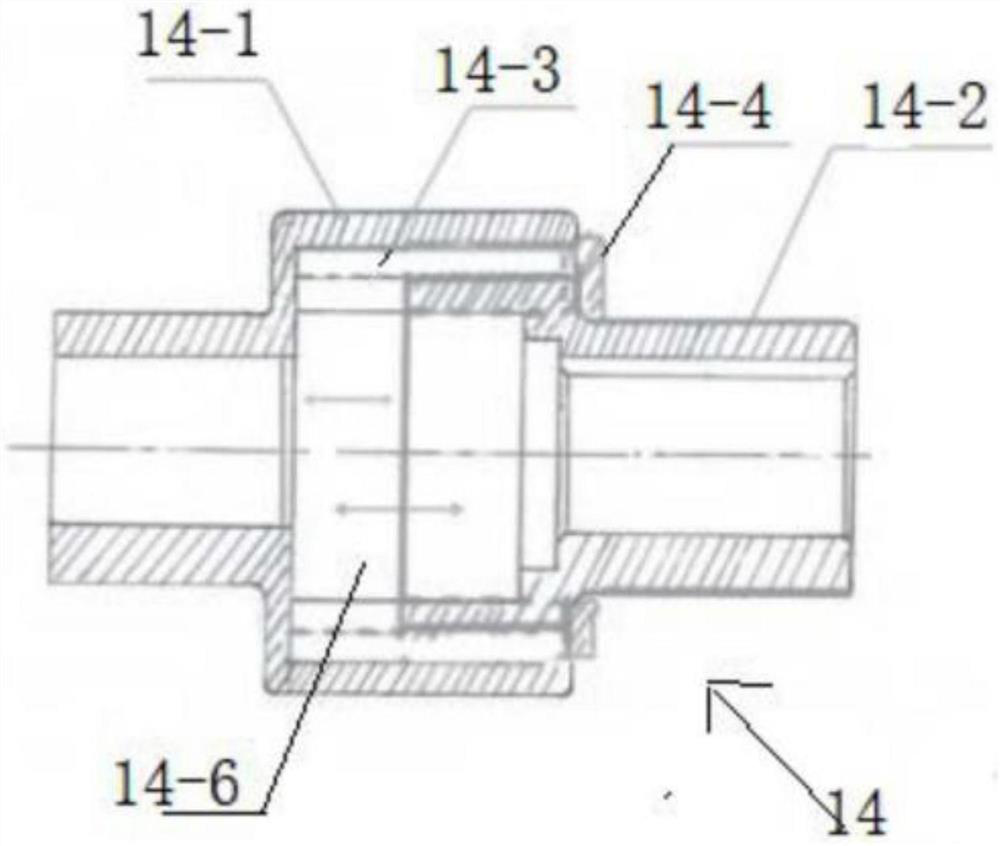

[0058] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , in this embodiment, an energy-saving straw decomposition machine that automatically controls the distance between the grinding discs, including a base 1 for fixing the straw decomposition machine, a main motor 12 fixed at one end of the base 1, and a motor shaft 13 for the main motor 12 It is affixed to the stretchable coupling 14, the stretchable coupling 14 is affixed to one end of the main rotating shaft 15, and the main rotating shaft 15 passes through the fixed seat 16, and the fixed seat 16 is used to support The main rotating shaft 15 in the rotating state, the other end of the main rotating shaft 15 penetrates into the slurry chamber 17 and is fixedly connected with the moving grinding disc 17-1, and the moving grinding disc 17-1 is fixed to the slurry chamber 17 The fixed grinding disc 17-2 inside is opposite, and the slurry after grinding flows out from the slurry outlet 17-4 of the slurry cha...

Embodiment 2

[0079] Referring to Example 1 figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The difference between the energy-saving straw decomposer of embodiment 2 and embodiment 2 is that the power source equipment of the straw decomposer of embodiment 2 is preferably a cylinder (not shown), and the cylinders are provided with 6 groups. The 6 groups of cylinders are centrally symmetrically arranged on the connected rear plate 16-3, the dial blades 113-1 are set to 3 pieces, the diameter of the feeding funnel 113 is 1 meter, and the front coupling sleeve Twelve circular holes 14-5 are provided at the joints between 14-1 and the rear coupling sleeve 14-2. The inertia wheel 111 is made of a hard non-metal material (such as resin, emery or silicon carbide), and the first hydraulic rod 112-1 is made of a hard non-metal material (such as resin, emery or silicon carbide). a) made. The outer cover and bearing assembly are made of hard non-metallic materials (such as resin, corund...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com