Electric heating fusion connection type modified sulfur concrete pipe and manufacturing method thereof

A sulphur concrete, electrothermal melting technology, applied in rigid pipes, manufacturing tools, pipes/pipe joints/fittings, etc., to achieve the effect of good sealing, simple and reliable connection, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

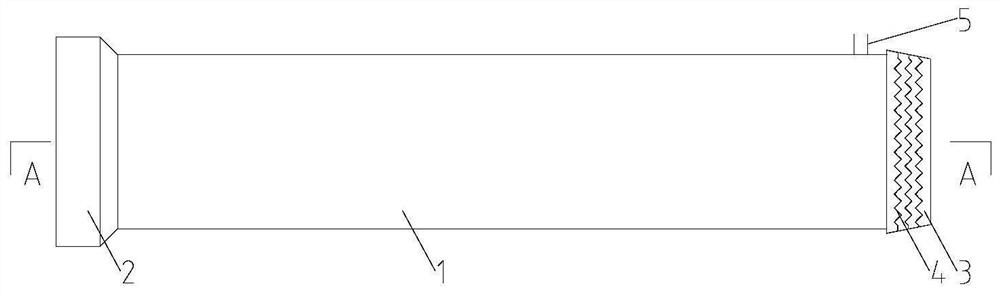

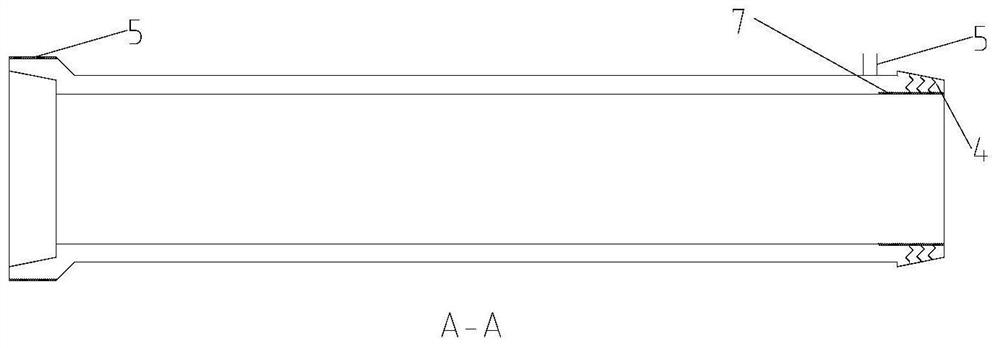

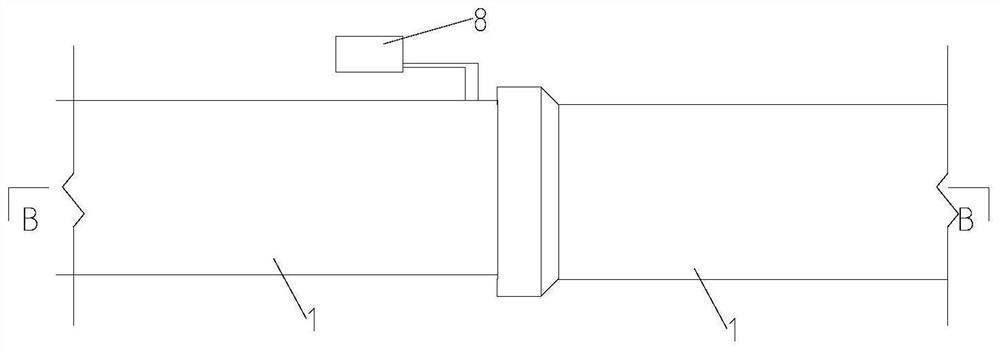

[0041] An electrothermally welded modified sulfur concrete pipe, such as Figure 1 ~ Figure 4 As shown, it includes several sections of pipe fittings inserted sequentially. One end of each section of pipe fitting is a tapered socket, and the other end is a tapered socket. There are multiple coils of electric heating wire 4 wound around the outer periphery, the electric heating wire is wound in a spiral manner, and an electrode joint for connecting to a power supply is provided. The electric heating wire heats up after being energized so that the inner and outer walls of the front and rear pipe fittings are thermally fused and fixed together. The outer wall of the tapered socket and the inner wall of the tapered socket are respectively wrapped with a steel plate lining ring to prevent the material from being softened and deformed by overheating.

[0042] The formula materials of the pipe fittings are (by mass parts): 15% of modified sulfur, 14% of cement micropowder, 51% of gr...

Embodiment 2

[0053] The structure of the pipe fittings in this example is the same as in the first embodiment.

[0054] The formula materials of the pipe fittings are (by mass parts): modified sulfur 17%, mineral powder 14%, granite coarse aggregate 50%, machine-made sand 19%;

[0055] Described modified sulfur formula material is (by mass): waste rubber powder 40%, sulfur 60%;

[0056] The preparation steps of the pipe fittings are as in Example 1.

[0057] The compressive strength of this modified sulfur concrete pipe fitting reaches 61.1MPa, and the flexural strength reaches 12.5MPa.

Embodiment 3

[0059] The structure of the pipe fittings in this example is the same as in the first embodiment.

[0060] The formula materials of the pipe fittings are (in parts by mass): 16% of modified sulfur, 13% of quartz powder, 50% of granite coarse aggregate, and 21% of quartz sand.

[0061] Described modified sulfur formulation material is (by mass): waste rubber powder 42%, sulfur 58%;

[0062] The preparation steps of the pipe fittings are as in Example 1.

[0063] The compressive strength of this modified sulfur concrete pipe fitting reaches 63.4MPa, and the flexural strength reaches 10.3MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com