Bearing and ablative thermal protection integrated composite missile wing and rudder for hypersonic missile, and preparation method of bearing and ablative thermal protection integrated composite missile wing and rudder

A hypersonic, composite material technology, used in offensive equipment, projectiles, weight reduction, etc., can solve problems such as poor strength, and achieve the effect of increasing effective range and reducing inertial mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method for a hypersonic projectile bearing, ablation and heat-resistant integrated composite projectile wing and rudder, comprising the following steps:

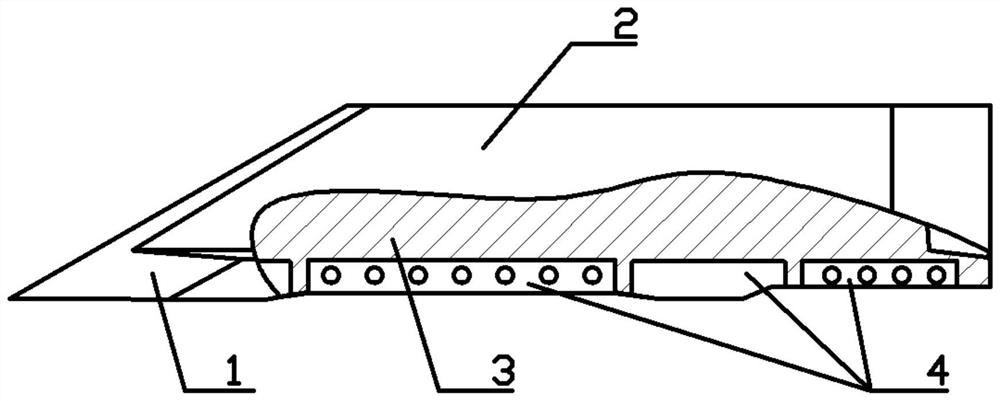

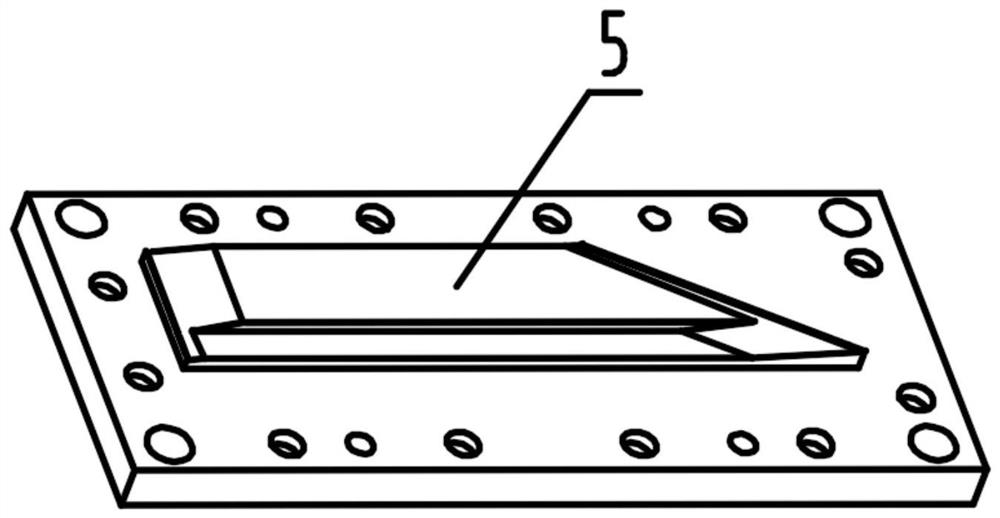

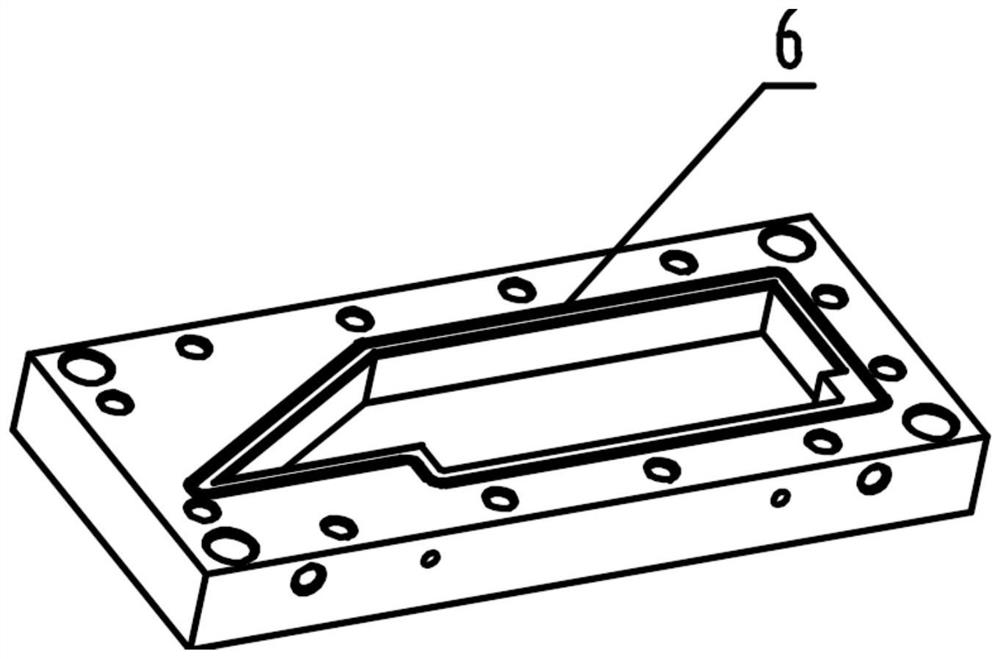

[0048] 1) According to the different models of hypersonic missiles, the requirements for airflow temperature, ablation time, and wingtip displacement under aerodynamic load of the wings and rudders are also different. The overall lay-up structure design of wings and rudders is divided into two parts, namely The wing and rudder load-bearing layer 3 and the ablation-resistant layer 2 of the wing and rudder;

[0049] Using abaqus software to simulate and analyze the load bearing and aerodynamic heating forms of the wing and rudder, it is required that the temperature of the inner wing and rudder bearing layer 3 is lower than the vitrification of the resin system under the condition of bearing the load and heating at high temperature Transition temperature (Tg), in order to avoid the overall deformation > 2m...

Embodiment 2

[0063] A preparation method for a hypersonic projectile bearing, ablation and heat-resistant integrated composite projectile wing and rudder, comprising the following steps:

[0064] 1) According to the different models of hypersonic missiles, the requirements for airflow temperature, ablation time, and wingtip displacement under aerodynamic load of the wings and rudders are also different. The overall lay-up structure design of wings and rudders is divided into two parts, namely The wing and rudder load-bearing layer 3 and the ablation-resistant layer 2 of the wing and rudder;

[0065] Using abaqus software to simulate and analyze the load bearing and aerodynamic heating forms of the wing and rudder, it is required that the temperature of the inner wing and rudder bearing layer 3 is lower than the vitrification of the resin system under the condition of bearing the load and heating at high temperature Transition temperature (Tg), in order to avoid the overall deformation > 2m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com