A kind of fast bonding method of soft board cover film

A covering film and soft board technology, which is applied to the improvement of the metal adhesion of insulating substrates, manufacturing tools, and machine tools suitable for grinding the edge of workpieces. The effect of improving the adhesion strength, glue adhesion is firm, and reducing the probability of degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

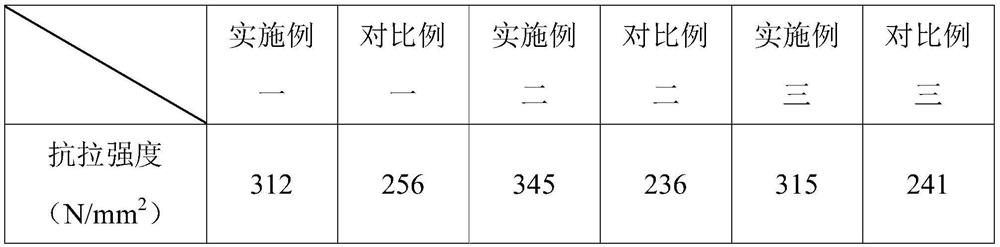

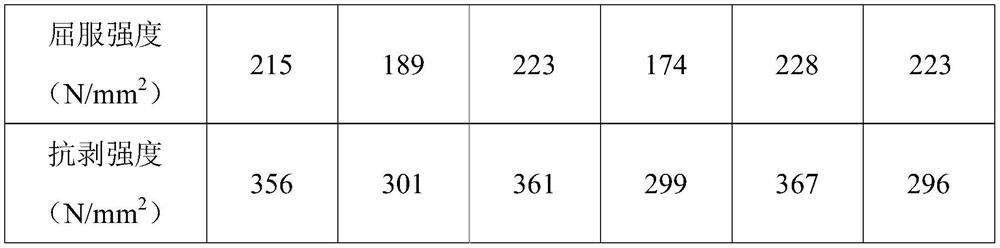

Embodiment 1

[0018] Embodiment 1 The hard board is an aluminum substrate

[0019] Lay the backing paper and the soft board cover film, and cut the backing paper and the soft board cover film into the same shape by laser cutting. The laser cutting frequency is 50kHz, the cutting speed is 350mm / s, the cutting power is 3W, and the cutting process uses nitrogen gas. As a protective gas, the preset nitrogen pressure is 1.0Mpa before cutting; rinse the soft board cover film with running water for 30s, dry it, and then use a steel brush to brush out the hair on the rubber-coated area of the soft board cover film, and the thickness of the hair layer is 0.3mm;

[0020] Lay the cut backing paper on the rubber-coated surface of the hard board, use the scribe method to locate the milling groove, and then perform the following pretreatment on the rubber-coated surface of the hard board:

[0021] Milling: fix the hard plate on the fixture, use MX230 milling cutter with a diameter of 1mm, the milling c...

Embodiment 2

[0026] Embodiment 2 The copper substrate is a hard board

[0027] Lay the pad paper and the soft board cover film, and cut the pad paper and the soft board cover film into the same shape by laser cutting method. The laser cutting frequency is 60kHz, the cutting speed is 450mm / s, the cutting power is 5W, and the cutting process uses nitrogen gas. As a protective gas, the preset nitrogen pressure is 1.0Mpa before cutting; rinse the soft board cover film with running water for 30s, dry it, and then use a steel brush to brush out the hair on the rubber-coated area of the soft board cover film, and the thickness of the hair layer is 0.5mm;

[0028] Lay the cut backing paper on the rubber-coated surface of the hard board, use the scribe method to locate the milling groove, and then perform the following pretreatment on the rubber-coated surface of the hard board:

[0029] Milling: Fix the hard plate on the fixture, use MX230 milling cutter with a diameter of 1mm, the milling cutte...

Embodiment 3

[0034] Embodiment 3 The nickel-based plate is a hard plate

[0035] Lay the backing paper and the soft board cover film, and cut the backing paper and the soft board cover film into the same shape by laser cutting. The laser cutting frequency is 55kHz, the cutting speed is 400mm / s, the cutting power is 4W, and the cutting process uses nitrogen gas. As a protective gas, the preset nitrogen pressure is 1.0Mpa before cutting; rinse the soft board cover film with running water for 30s, dry it, and then use a steel brush to brush out the hair on the rubber-coated area of the soft board cover film, and the thickness of the hair layer is 0.4mm;

[0036] Lay the cut backing paper on the rubber-coated surface of the hard board, use the scribe method to locate the milling groove, and then perform the following pretreatment on the rubber-coated surface of the hard board:

[0037] Milling: fix the hard plate on the fixture, use MX230 milling cutter with a diameter of 1mm, the milling cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com